Method for preparing hydroxyapatite nanocrystals or microcrystals by using plant as template

A hydroxyapatite and nanocrystal technology, applied in the field of material chemistry, can solve problems such as unreported and unreported hydroxyapatite particles, and achieve the effects of easy removal, industrialization promotion, and increased specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

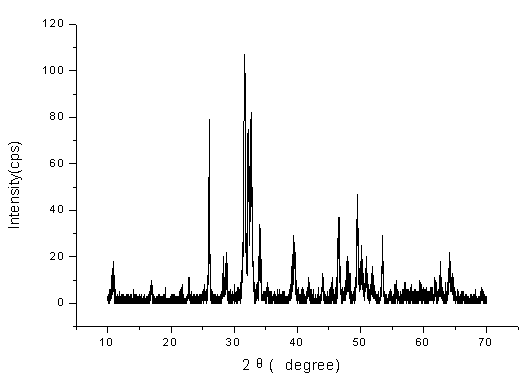

Image

Examples

Embodiment 1

[0043] Example 1: The method for preparing hydroxyapatite nanocrystals or microcrystals using plants as a template is as follows:

[0044] (1) Dissolve diammonium hydrogen phosphate in deionized water, stir to completely dissolve it into a uniform transparent solution, add cotton as a plant template, and dissolve 0.05 moles of diammonium hydrogen phosphate per liter of deionized water, per liter of phosphate Add 1g of plant template to the solution;

[0045] (2) Stir the phosphate solution at 400 rpm, and place it in an oil bath at 25°C for 24 hours. While the oil bath is constant, add calcium carbonate to the phosphate solution while stirring. The constant temperature is over After that, continue to stir for 30 minutes, then sonicate for 15 minutes, and finally cool to room temperature naturally, where the molar ratio of Ca:P is 1.67, and the pH of the solution is maintained at 8 (adjust the pH with sodium hydroxide);

[0046] (3) Filter the liquid obtained in step (2), collect th...

Embodiment 2

[0049] Example 2: The method for preparing hydroxyapatite nanocrystals or microcrystals using plants as a template is as follows:

[0050] (1) Dissolve sodium phosphate in deionized water, stir to make it completely dissolve into a uniform transparent solution, add cotton as a plant template; in which 0.1 mole of sodium phosphate is dissolved per liter of deionized water, and 3g per liter of phosphate solution is added (2) Stir the phosphate solution at 450 rpm and place it in an oil bath at a constant temperature of 50°C for 9 hours. While the oil bath is at a constant temperature, add calcium carbonate while stirring the phosphate solution After the constant temperature is over, continue to stir for 45 minutes, then ultrasonic for 30 minutes, and finally cool to room temperature naturally, where the molar ratio of Ca:P is 1.67, and the pH value of the solution is maintained at 8.5 (the pH value is adjusted with potassium hydroxide);

[0051] (3) Filter the liquid obtained in ste...

Embodiment 3

[0054] Example 3: The method for preparing hydroxyapatite nanocrystals or microcrystals using plants as a template is as follows:

[0055] (1) Dissolve sodium monohydrogen phosphate in deionized water, stir to make it completely dissolve into a uniform transparent solution, add cotton to it as a plant template; among them, dissolve 1 mole of sodium monohydrogen phosphate per liter of deionized water, per liter of phosphate Add 6g of cotton template to the solution;

[0056] (2) Stir the phosphate solution at 800rpm, and place it in an oil bath at 45℃ for 18h. While the oil bath is constant, the calcium nitrate solution is dripped at a speed of 5ml / min while stirring. Add the phosphate solution, after the constant temperature is over, continue to stir for 30 minutes, then sonicate for 25 minutes, and finally cool to room temperature naturally, where the molar ratio of Ca:P is 1.67, and the pH value of the solution is maintained at 10 (adjust the pH value with ammonia);

[0057] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com