Process for processing arc-shaped spring

A processing technology and arc-shaped technology, which is applied in the field of arc-shaped spring processing technology, can solve the problems of low yield, unsatisfactory spring consistency, and low production efficiency, and achieve low cost, easy control of parameters, and good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

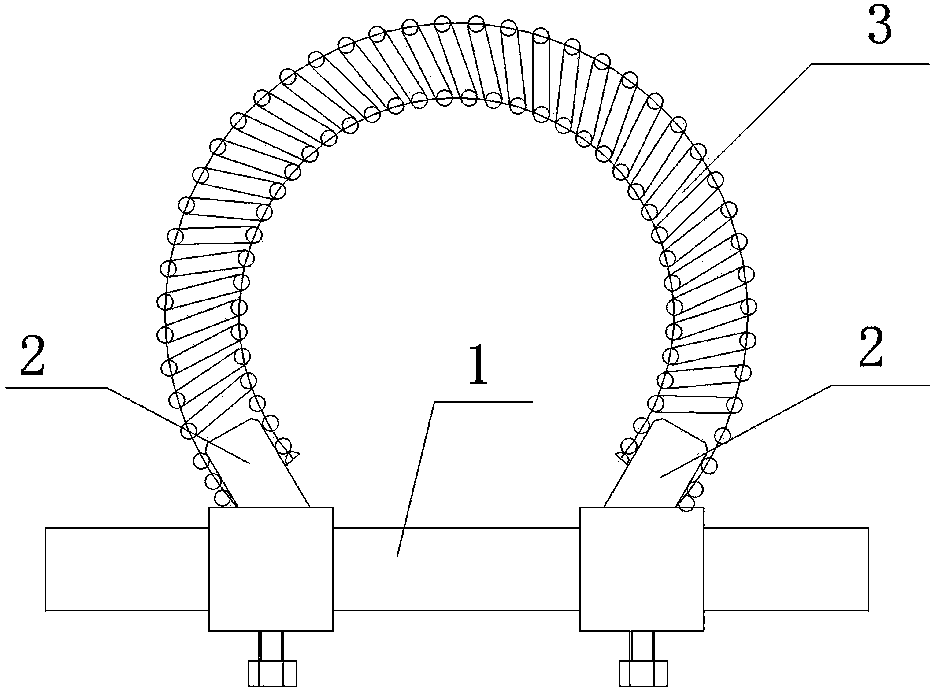

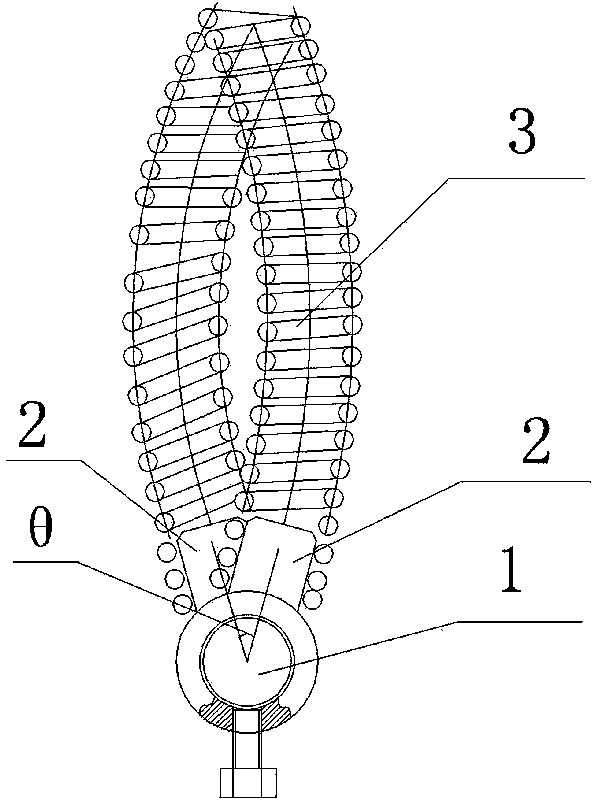

[0047] A processing technology for arc springs, which uses OTEVA 75SC material as the raw material for processing, checks the raw materials and eliminates unqualified products, and rolls the spring. The spring coiling is carried out on a computer numerical control spring coiling machine with more than four axes. The steel wire blank is wound into a cylindrical coil spring by tightening the two ends of the spring according to the prefabricated height, outer diameter and number of turns. After coiling the spring, keep the annealing temperature at 410°C in the tempering furnace for stress relief annealing, the holding time is 60 minutes, and the residual stress on the surface of the spring is less than 150Mpa. After annealing, grind the two ends of the spring, the grinding angle is 270~330 degrees, and the remaining thickness of the end is greater than 0.15d (d is the diameter of the steel wire). The center of the bow-shaped spring is bent to form a bow-shaped spring. The angle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com