Rubber compound for ultrahigh voltage post insulator and preparation method thereof

A composite insulator and ultra-high voltage technology, applied in the field of rubber material manufacturing, can solve the problems of easy scorch of rubber materials, shed tearing, air bubbles, etc., and achieve the effect of excellent mold release and long scorch period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

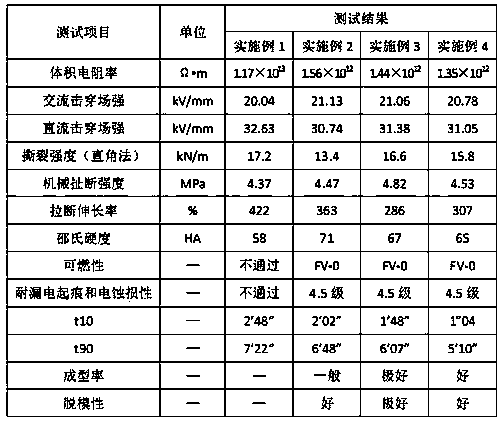

Embodiment 1

[0052] A compound rubber formula for UHV pillar composite insulators and its preparation method, the preparation method is as follows: put 120 parts of methyl vinyl silicone rubber with a vinyl content of 0.08% into a vacuum kneader, and put 0.4 parts of stearic acid , 0.5 parts of boric acid, 0.5 parts of vinyltrimethoxysilane, 40 parts of white carbon black are added in 4 times, and 10 parts of hydroxyl silicone oil are added in 4 times. The material must form a group before each new feeding. After the last feed into agglomerates, heat up until the rubber material reaches 155±5°C, heat-treat for 60 minutes, discharge and park for more than 24 hours to obtain silica rubber; put 80 parts of methyl ethylene with a vinyl content of 0.16% into the vacuum kneader Based silicone rubber, put 2 parts of zinc oxide, 0.4 parts of stearic acid, 0.5 parts of vinyltrimethoxysilane, 70 parts of aluminum hydroxide with a median particle size of 1-2 μm and 70 parts of hydrogen with a median p...

Embodiment 2

[0055]A compound rubber formula for UHV pillar composite insulators and its preparation method, the preparation method is as follows: put 130 parts of methyl vinyl silicone rubber with a vinyl content of 0.08% into a vacuum kneader, and put 0.5 parts of stearic acid , 0.6 parts of boric acid, 0.6 parts of vinyltrimethoxysilane, 50 parts of white carbon black are added in 4 times, and 11 parts of hydroxy silicone oil are put in in 4 times. The material must be agglomerated before each new feeding. After the last feed into agglomerates, heat up until the rubber material reaches 155±5°C, heat treatment for 60 minutes, discharge and park for more than 24 hours to obtain silica rubber; put 90 parts of methyl ethylene with a vinyl content of 0.16% into the vacuum kneader Base silicone rubber, put 4 parts of zinc oxide, 0.5 parts of stearic acid, 0.6 parts of vinyltrimethoxysilane, 110 parts of aluminum hydroxide with a median particle size of 1-2 μm and 110 parts of hydrogen with a m...

Embodiment 3

[0058] A compound rubber formula for UHV pillar composite insulators and its preparation method, the preparation method is as follows: put 140 parts of methyl vinyl silicone rubber with a vinyl content of 0.08% into a vacuum kneader, and put 0.6 parts of stearic acid , 0.7 parts of boric acid, 0.7 parts of vinyltrimethoxysilane, 60 parts of white carbon black are added in 4 times, and 10 parts of hydroxyl silicone oil are put in in 4 times. The material must form a group before each new feeding. After the last feed into agglomerates, heat up until the rubber material reaches 155±5°C, heat treatment for 60 minutes, discharge and park for more than 24 hours to obtain silica rubber; put 100 parts of methyl ethylene with a vinyl content of 0.16% into the vacuum kneader Based silicone rubber, put 6 parts of zinc oxide, 0.6 parts of stearic acid, 0.7 parts of vinyltrimethoxysilane, 110 parts of aluminum hydroxide with a median particle size of 1-2 μm and 110 parts of hydrogen with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com