Sulfur removal agent suitable for production of oil-gas well

A technology of oil and gas wells and alcohol amines, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems affecting the production of oil and gas wells, blocking oil and gas channels, etc., and achieve the effect of rapid response and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

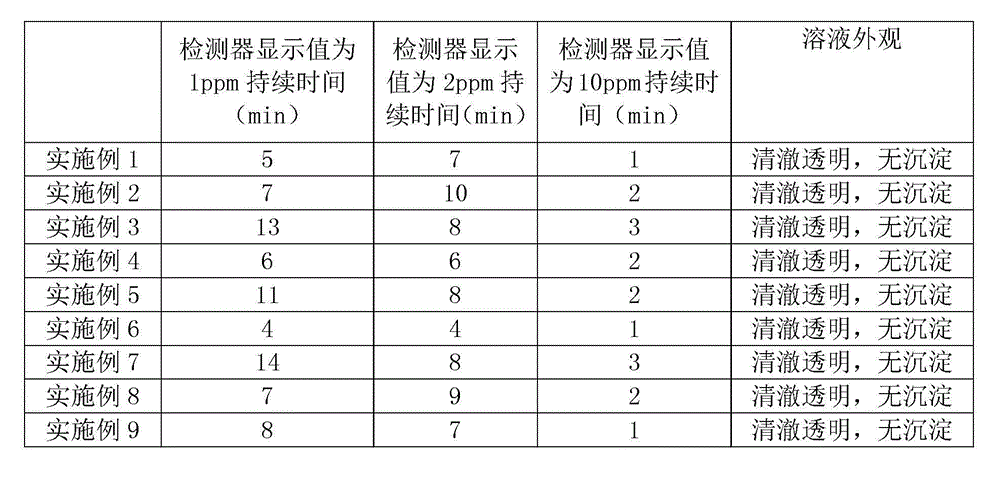

Examples

Embodiment 1

[0019] Put 20g of methanol into a 500ml three-necked flask, then add 30g of hydroxyethylhexahydro-s-triazine and 20g of triethanolamine, stir for 30 minutes, add 130g of water, stir for 10 minutes and mix well to obtain the product.

Embodiment 2

[0021] Put 10g of ethanol in a 500ml three-necked flask, then add 50g of hydroxyethylhexahydro-s-triazine and 10g of methyldiethanolamine, stir for 20 minutes, add 130g of water, stir for 10 minutes and mix well to obtain the product.

Embodiment 3

[0023] Put 40g of methanol into a 500ml three-necked flask, then add 20g of hydroxyethylhexahydro-s-triazine and 40g of monoethanolamine, stir for 40 minutes, add 100g of water, stir for 10 minutes and mix well to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com