Puffing feed for preventing whitening of black carp body color and preparation method thereof

A technology of extruded feed and body color, applied in animal feed, animal feed, application, etc., to achieve good palatability, increase market share, and enhance body color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

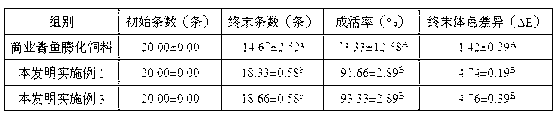

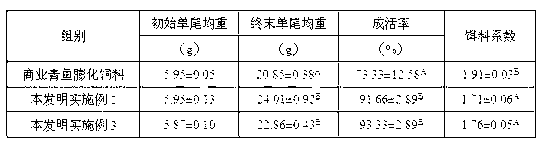

Examples

Embodiment 1

[0025] Present embodiment prepares 100kg extruded feed, and its preparation method is:

[0026] 1) Weigh the following raw materials respectively: fish meal 11kg, peeled soybean meal 24kg, rapeseed meal 11kg, squid paste 3.5kg, meat and bone meal 7kg, beer yeast 3.5kg, pine needle powder 4kg, locust leaf powder 3.5kg, seaweed powder 3.5kg, Vitamin C phosphate 0.12kg, choline chloride 0.38kg, corn gluten powder 5.5kg, flour 19kg, soybean oil 1kg, calcium dihydrogen phosphate 1.5kg, fish premix 1.5kg;

[0027] 2) Mix the above-mentioned weighed raw materials evenly, and pulverize them with a superfine pulverizer produced by Wuhan Mingbo Equipment Co., Ltd. (model SWFL130), so that all raw materials can pass through the 80-mesh screen;

[0028] 3) Put the pulverized material into the conditioner, pass through 13kg, 93°C water vapor for conditioning for 8 minutes, and then make the raw material enter the extrusion granulator at a temperature of 95°C for granulation;

[0029] 4) D...

Embodiment 2

[0032] Present embodiment prepares 100kg extruded feed, and its preparation method is:

[0033] 1) Weigh the following raw materials respectively: fish meal 12kg, peeled soybean meal 20kg, rapeseed meal 14kg, squid paste 2.5kg, meat and bone meal 9kg, brewer’s yeast 3.5kg, pine needle powder 4kg, locust leaf powder 3.5kg, seaweed powder 3.5kg, Vitamin C phosphate 0.1kg, choline chloride 0.4kg, corn gluten powder 4.5kg, flour 19kg, soybean oil 1kg, calcium dihydrogen phosphate 1.5kg, fish premix 1.5kg;

[0034] 2) Mix the above-mentioned weighed raw materials evenly, and pulverize them with a superfine pulverizer produced by Hubei Sanjiang Co., Ltd. (model TDCWF.132), so that all raw materials can pass through the 80-mesh screen;

[0035] 3) Put the pulverized material into the conditioner, pass through 13kg, 95°C water vapor for conditioning for 7 minutes, and then let the raw material enter the extrusion granulator at a temperature of 97°C for granulation;

[0036] 4) Dry th...

Embodiment 3

[0039] Present embodiment prepares 100kg extruded feed, and its preparation method is:

[0040] 1) Weigh the following raw materials respectively: fish meal 11kg, peeled soybean meal 23kg, rapeseed meal 12kg, squid paste 2.5kg, meat and bone meal 8kg, beer yeast 3.5kg, pine needle powder 4kg, locust leaf powder 3.5kg, seaweed powder 3.5kg, Vitamin C phosphate 0.2kg, choline chloride 0.3kg, corn gluten powder 3.5kg, flour 21kg, soybean oil 1kg, calcium dihydrogen phosphate 1.2kg, fish premix 1.8kg;

[0041] 2) Mix the above-mentioned weighed raw materials evenly, and pulverize them with a superfine pulverizer produced by Wuhan Mingbo Equipment Co., Ltd. (model SWFL130), so that all raw materials can pass through the 80-mesh screen;

[0042] 3) Put the pulverized material into the conditioner, pass through 11kg of steam at 90°C for 8 minutes, and then let the raw material enter the extruder granulator at a temperature of 95°C for granulation;

[0043] 4) Dry the extruded feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com