Waterproofing method for stress monitoring cable joints for reinforced concrete segments

A reinforced concrete pipe and reinforced concrete technology, applied in the direction of cable terminals, can solve the problems of twisted pair wire exposure in the cable, poor reliability, and affecting the test effect of the stress state of the segment, so as to avoid abnormalities or even missing, and improve the test performance. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in conjunction with accompanying drawing and specific embodiment:

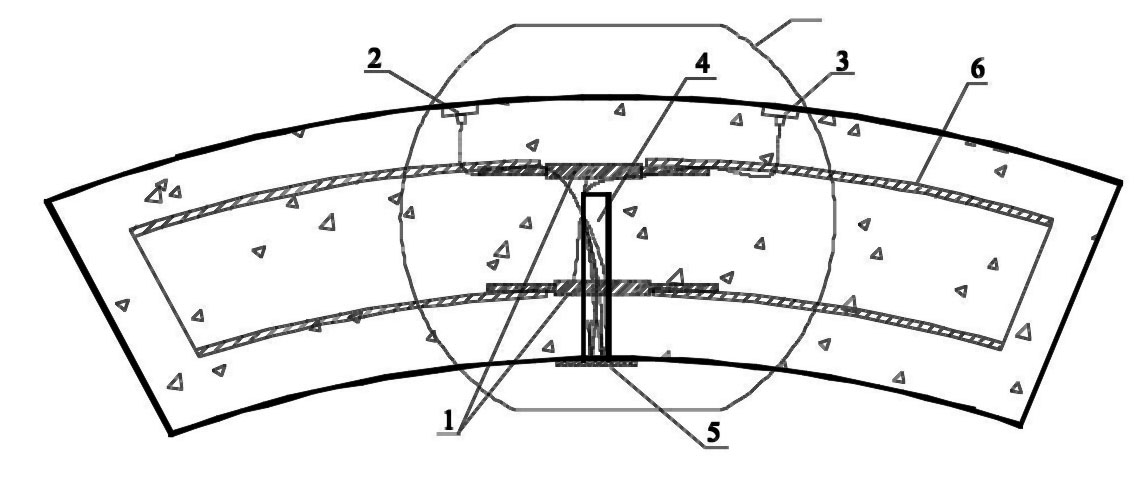

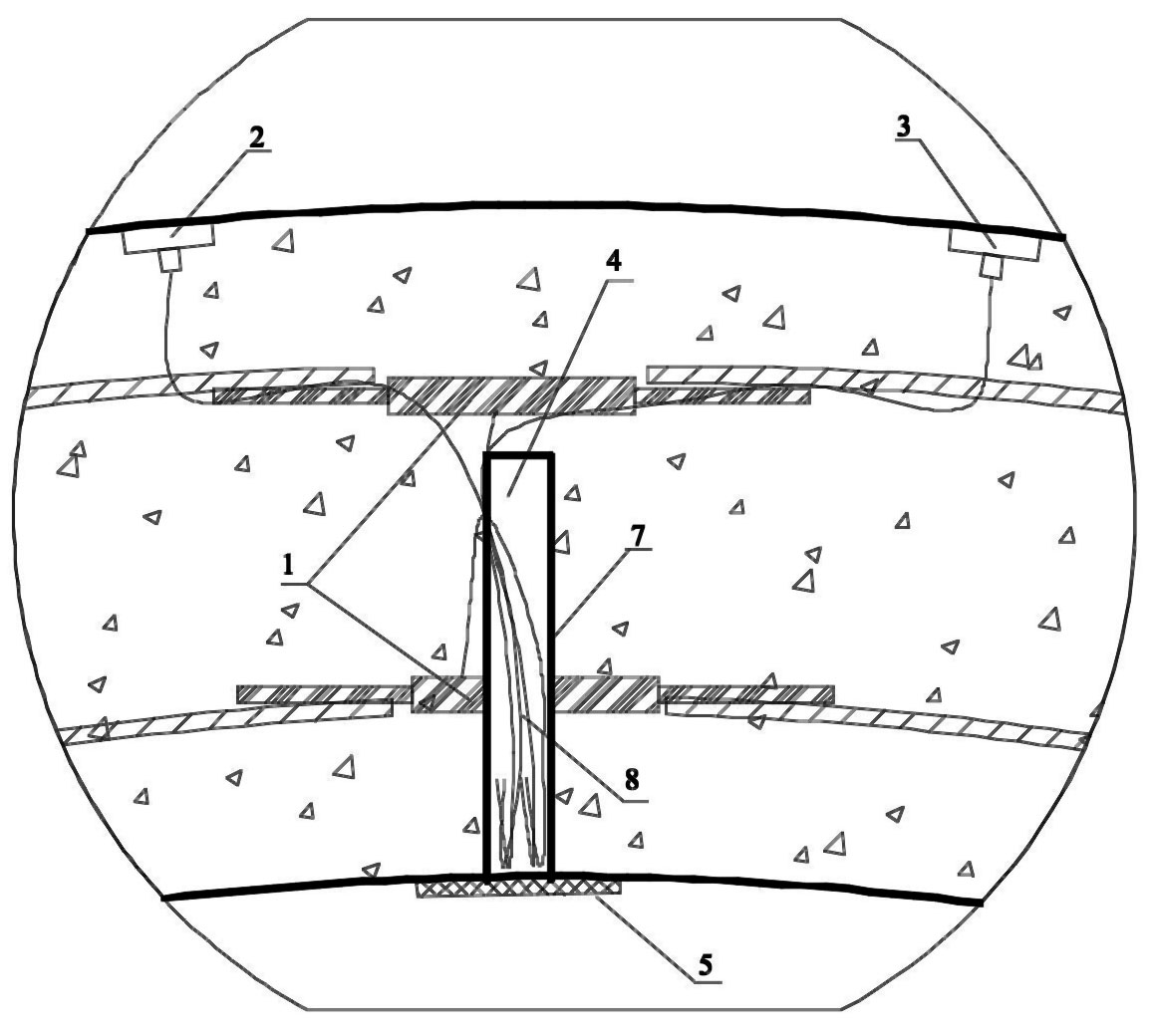

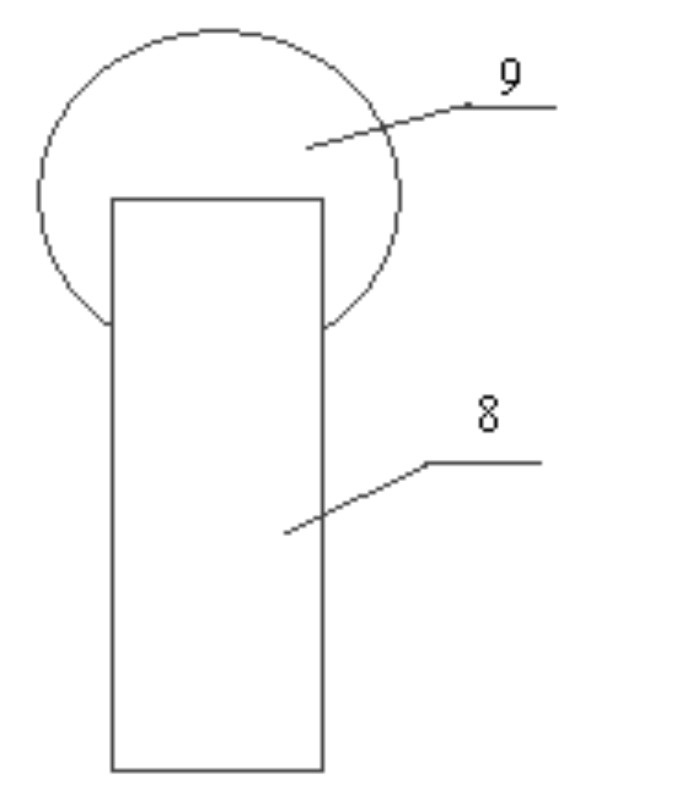

[0018] Such as Figure 1 to Figure 3 As shown, a method for waterproofing the cable joints of reinforced concrete segments under force monitoring, the specific steps are as follows: after the reinforced concrete segment reinforcement cage is put into the mould, before the concrete is poured, the steel bar gauge 1, the earth pressure gauge 2, the pore water The pressure gauge 3 forms the cable 8 of the monitoring element; bind the cable 8 of the monitoring element along the steel bar, cut off the reserved length and mark it well, and seal the cable 8 joint of the monitoring element to achieve preliminary waterproofing of the cable 8 joint The cable 8 connector passes through the pre-made hole on the plastic casing 7 of the grouting hole of the embedded part, stores the reserved cable 8 in the grouting hole 4, and seals the plastic casing 7 and the grouting hole with wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com