Lithium sulphur battery and manufacturing method thereof

A technology of lithium-sulfur battery and preparation process, which is applied in the field of electrochemical applications, and can solve the problems of limited lithium amount and lower specific energy of batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

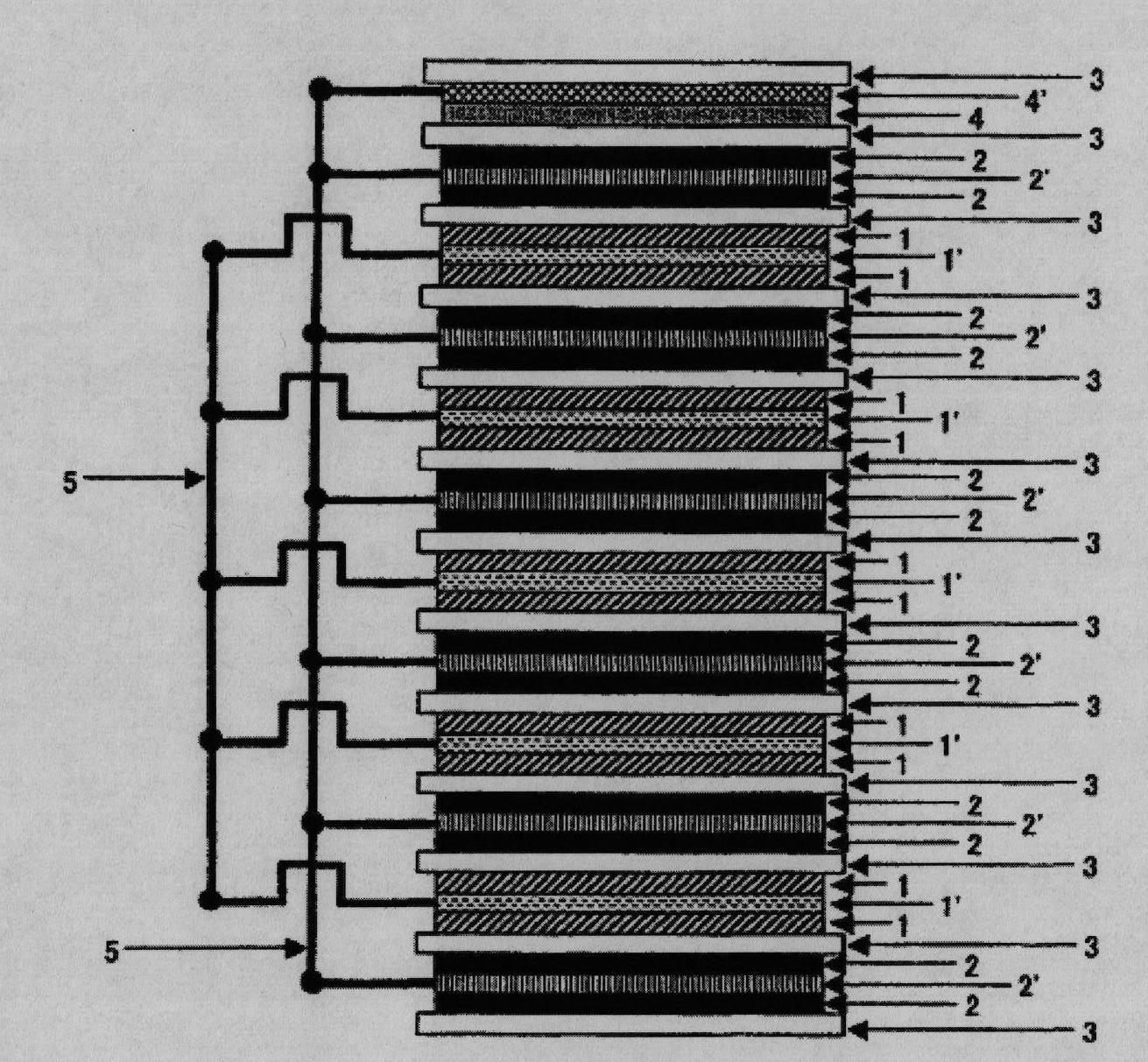

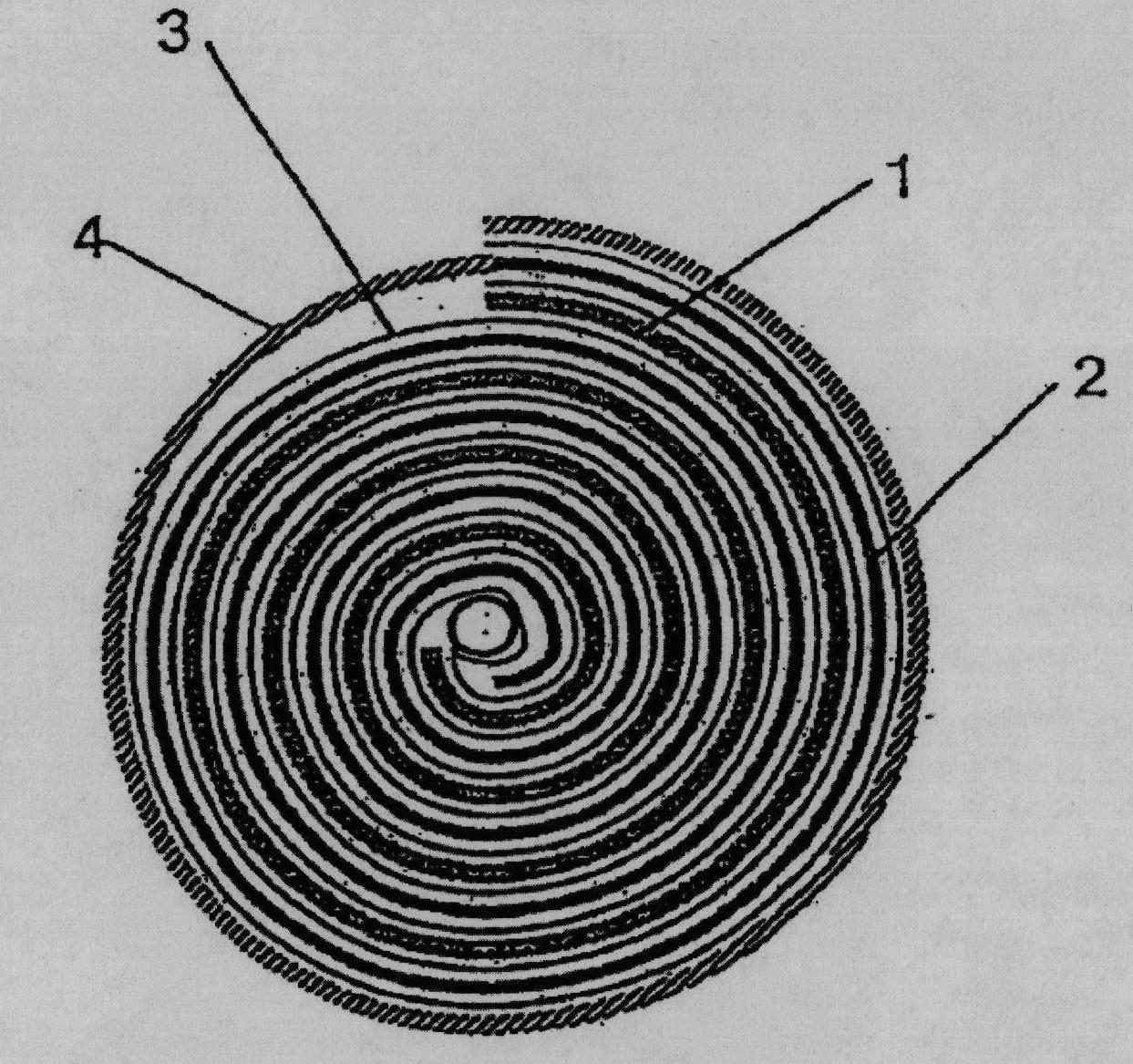

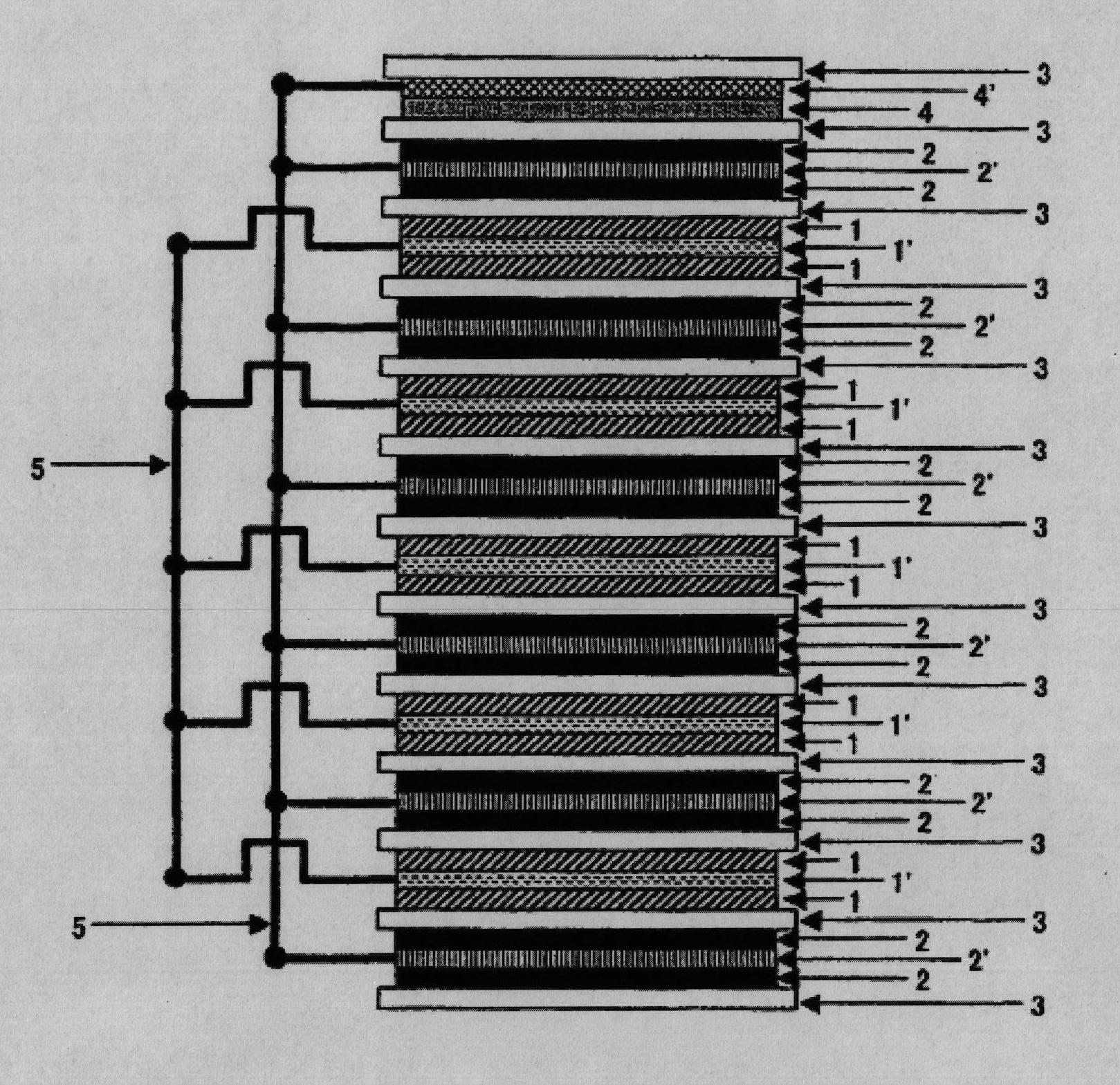

Image

Examples

Embodiment 1

[0020] Example 1: Using sublimed sulfur as the positive electrode, the sulfur powder, acetylene black and polyvinylidene fluoride (PVDF) were mixed uniformly at a mass ratio of 80:10:10, and N-methyl-2-pyrrolidone (NMP) was used as the solvent. Ball milled in a stainless steel ball mill tank at a speed of 250 rpm for 4 hours, and the obtained slurry was evenly coated on both sides of the current collector aluminum mesh, and then dried in a vacuum oven at 60°C for 20 hours. The coating thickness on both sides of the aluminum mesh was consistent. The thickness is 60 microns. Using natural graphite as the negative electrode, the graphite powder, acetylene black, and polyvinylidene fluoride (PVDF) are mixed uniformly at a mass ratio of 80:10:10, and N-methyl-2-pyrrolidone (NMP) is used as the solvent in a stainless steel ball mill tank. Ball mill at a speed of 250rpm for 2h, and evenly coat the obtained slurry on both sides of the current collector copper mesh, and then dry it in a...

Embodiment 2

[0023] Example 2: Using sublimed sulfur as the positive electrode, the sulfur powder, acetylene black and polyvinylidene fluoride (PVDF) were mixed uniformly at a mass ratio of 80:10:10, and N-methyl-2-pyrrolidone (NMP) was used as the solvent. Ball milled in a stainless steel ball mill tank at a speed of 250 rpm for 4 hours, and the obtained slurry was evenly coated on both sides of the aluminum foil of the current collector, and then dried in a vacuum oven at 80°C for 20 hours. The thickness of the coating on both sides of the aluminum mesh was consistent, and the total thickness was Is 60 microns. Using mesophase carbon microspheres as the negative electrode, the graphite powder, acetylene black and polyvinylidene fluoride (PVDF) are mixed uniformly at a mass ratio of 80:10:10, and N-methyl-2-pyrrolidone (NMP) is used as the solvent. Ball milled in a stainless steel ball mill tank at a speed of 250 rpm for 2 hours, the slurry will be uniformly coated on both sides of the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com