R-t-b rare earth sintered magnet

A R-T-B, sintered magnet technology, applied in the direction of permanent magnets, magnetic materials, magnetic objects, etc., can solve the problems of reduced residual magnetic flux density of permanent magnets, increased cost, expensive heavy rare earth elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

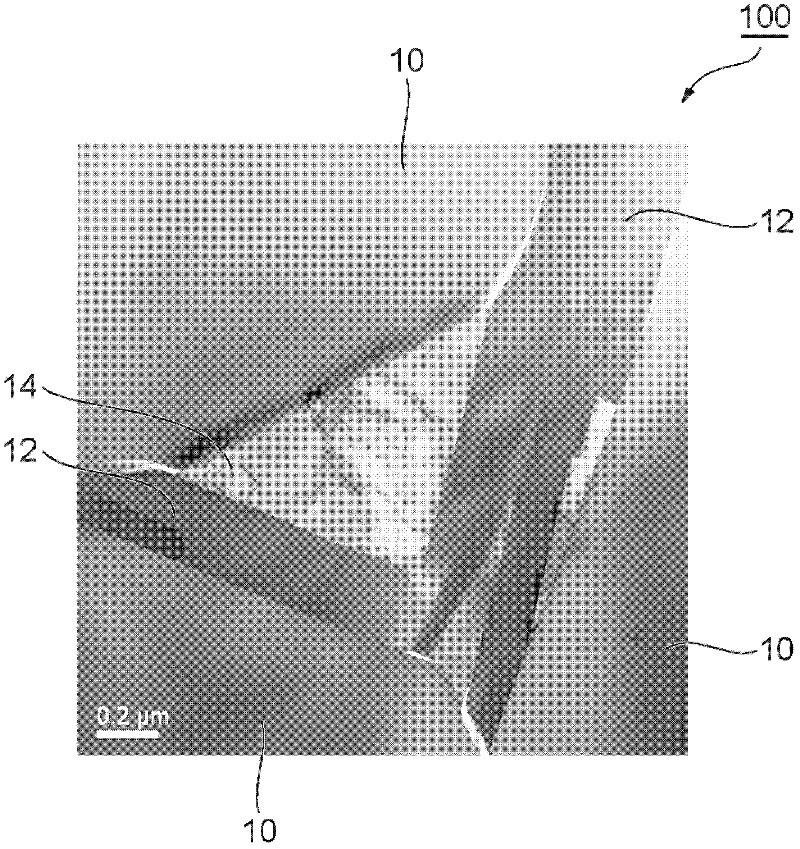

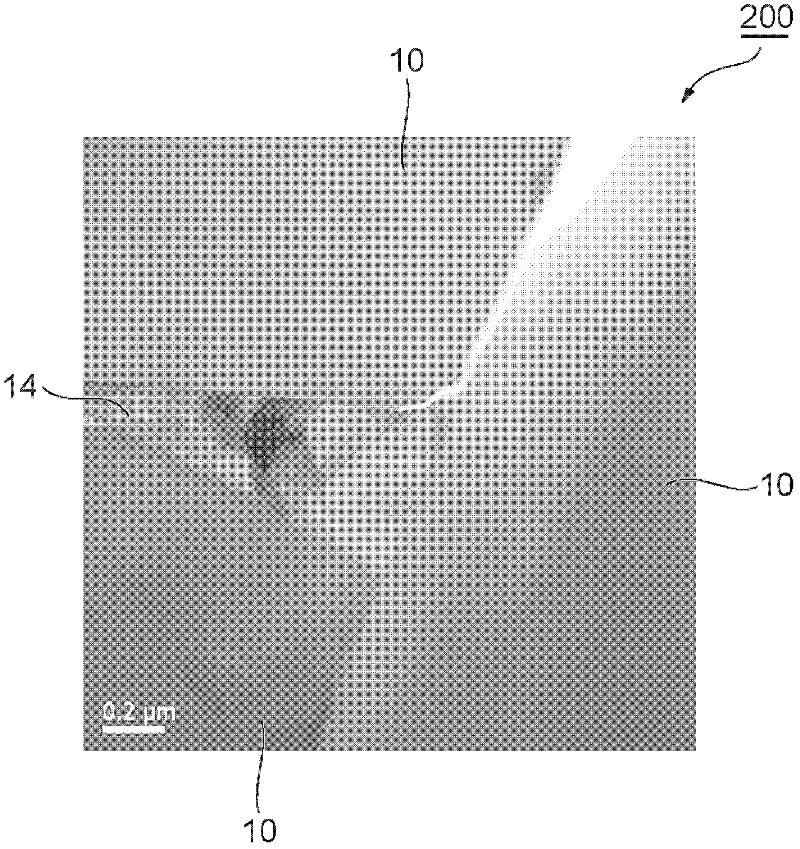

Image

Examples

Embodiment 1

[0058] (Example 1) Two types of alloys A and B having predetermined compositions were prepared by strip casting. In addition, both alloys A and B contain 0.2% by mass of Al (aluminum). Proportion and mix alloy A and alloy B according to the mass ratio of 9:1, and carry out coarse pulverization. Specifically, after allowing the mixed alloy to absorb hydrogen gas at room temperature, it was heated at 650° C. for 1 hour in an inert gas atmosphere to perform a dehydrogenation treatment to obtain a pulverized product. Thereafter, the obtained pulverized product was cooled to room temperature in an inert gas atmosphere.

[0059]10% by mass of lauric acid amide powder was added to the obtained pulverized product as a pulverization aid, and it was mixed for 30 minutes under an inert atmosphere using a Nauta mixer. Thereafter, it was pulverized with a high-pressure nitrogen jet mill to obtain a raw material fine powder having an average particle size (corresponding to a volume-based ...

Embodiment 2

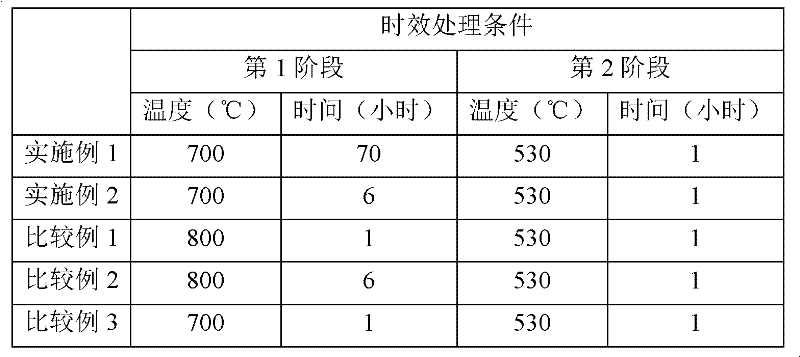

[0062] (Example 2, Comparative Examples 1-3)

[0063] R-T-B based rare earth sintered magnets were produced in the same manner as in Example 1, except that the conditions of the aging treatment were as shown in Table 1.

[0064] [Table 1]

[0065]

[0066] [Evaluation of Magnetic Properties]

[0067] Use a BH tracer (BH tracer) to measure the magnetic properties of the R-T-B series rare earth sintered magnets of each of the examples and comparative examples produced, and obtain Br (remanent magnetic flux density), HcJ (coercive force) and Hk / HcJ (squareness ratio). The obtained results are summarized in Table 2. The squareness ratio is obtained by the following formula (1) using HcJ and Hk. The squareness ratio is an index of magnet performance, and indicates the degree to which a hysteresis loop measured using a B-H recorder has an angle in the second quadrant. Hk in the formula (1) is the external magnetic field strength when the ratio of the magnetization to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com