Valve combination mode of high polymer material combined with ceramic and composite ball valve

A technology combining polymer materials and ceramics, applied in valve details, valve devices, valve housing structures, etc., can solve problems such as gaps, reduce production process complexity and production costs, reduce transportation energy consumption, service life and reliability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

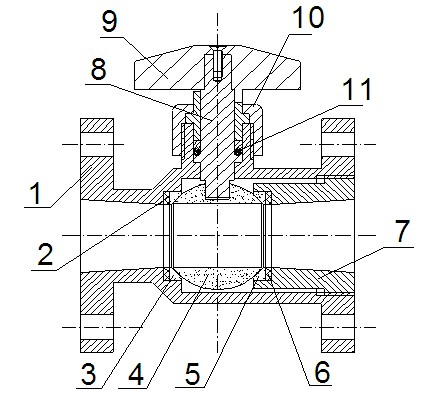

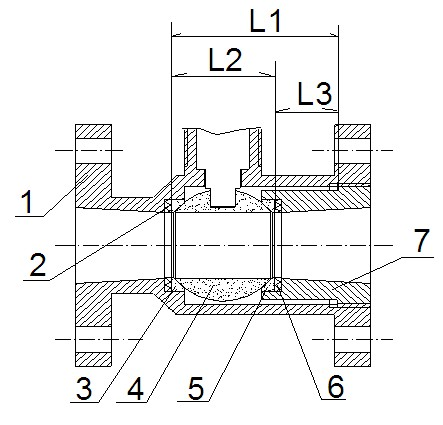

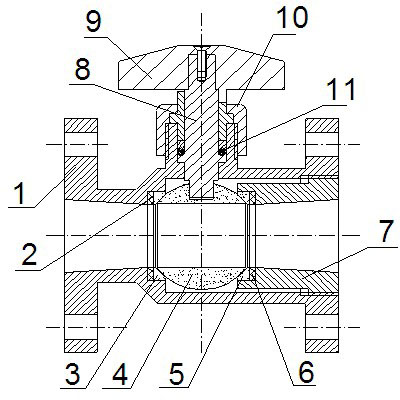

[0039] A spherical valve made of polymer materials and ceramics, consisting of a valve body 1, a left elastic washer 2, a left valve seat 3, a valve core 4, a right valve seat 5, a right elastic washer 6, a compensating compression sleeve 7, Valve stem 8, handle 9, gland 10, valve stem sealing ring 11 etc. are made up. The ceramic valve core 4, the left valve seat 3 and the right valve seat 5 are compressed by the threaded structure between the valve body and the compensating compression sleeve. The valve body is made of polymer material with a certain strength, the compensation compression sleeve is made of another polymer material with a different thermal expansion coefficient than that of the valve body material, and the elastic gasket is made of elastic polymer material. When the working temperature changes, when there is a difference in size between the valve body and the ceramic valve core and valve seat, the compensation compression sleeve realizes the main compensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com