Electric vehicle battery working temperature control device and method

A technology of working temperature and electric vehicles, applied in the direction of battery/fuel cell control devices, electric vehicles, control devices, etc., can solve problems such as no solutions, and achieve the effect of improving reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

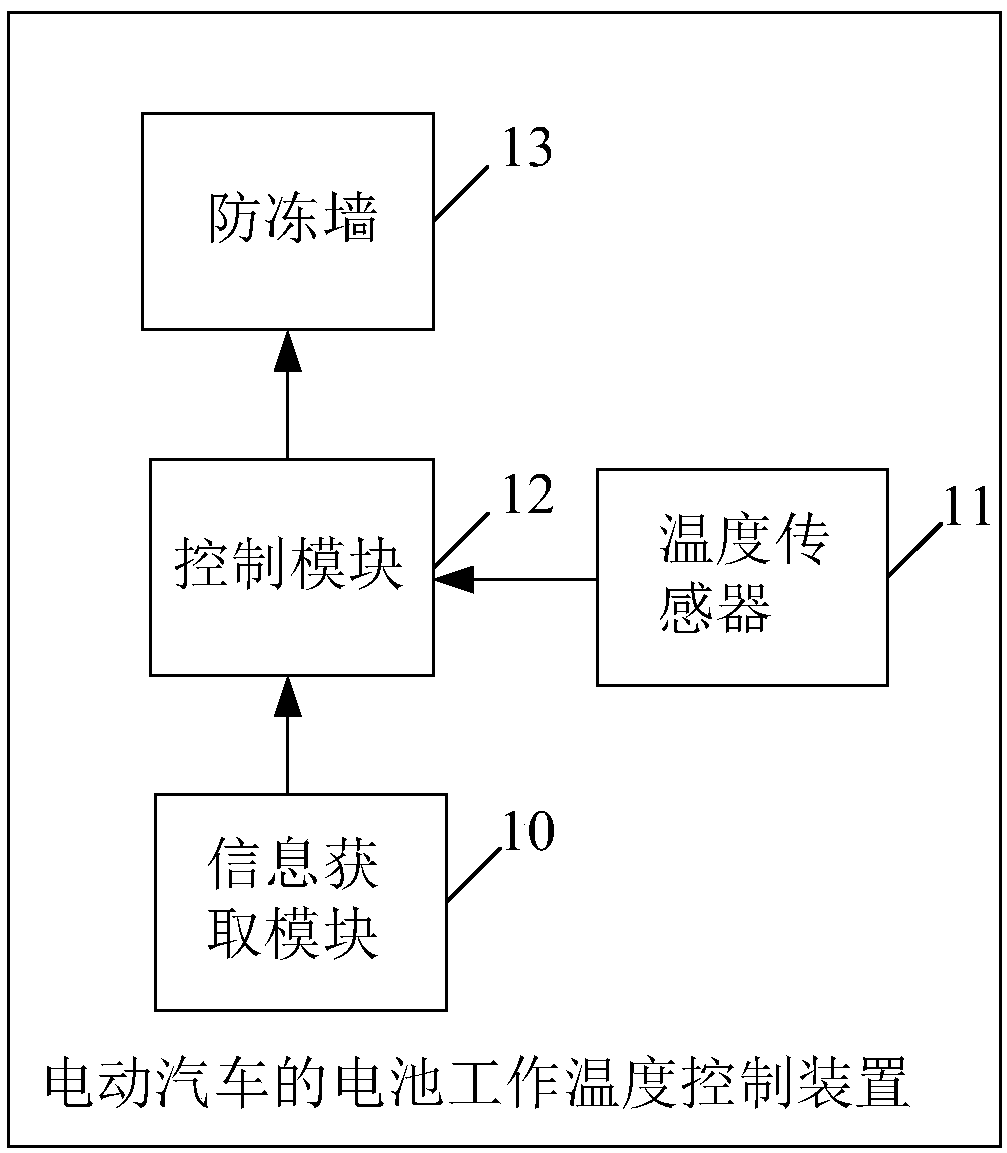

[0025] figure 1 It is a main structural block diagram of the battery operating temperature control device for electric vehicles provided by the first embodiment of the present invention. The battery operating temperature control device of the electric vehicle can automatically adjust the operating temperature of the battery, so that the battery maintains the best charging and discharging characteristics, and improves the reliability and service life of the battery. see figure 1 , the battery operating temperature control device of the electric vehicle includes: an information acquisition module 10 , a temperature sensor 11 , a control module 12 and an antifreeze wall 13 .

[0026] More specifically, the information acquisition module 10 is connected with the control module 12, and is used to acquire the battery charge and discharge state information and battery information when the vehicle power battery is working at different operating temperatures in each use stage, and cha...

no. 2 example

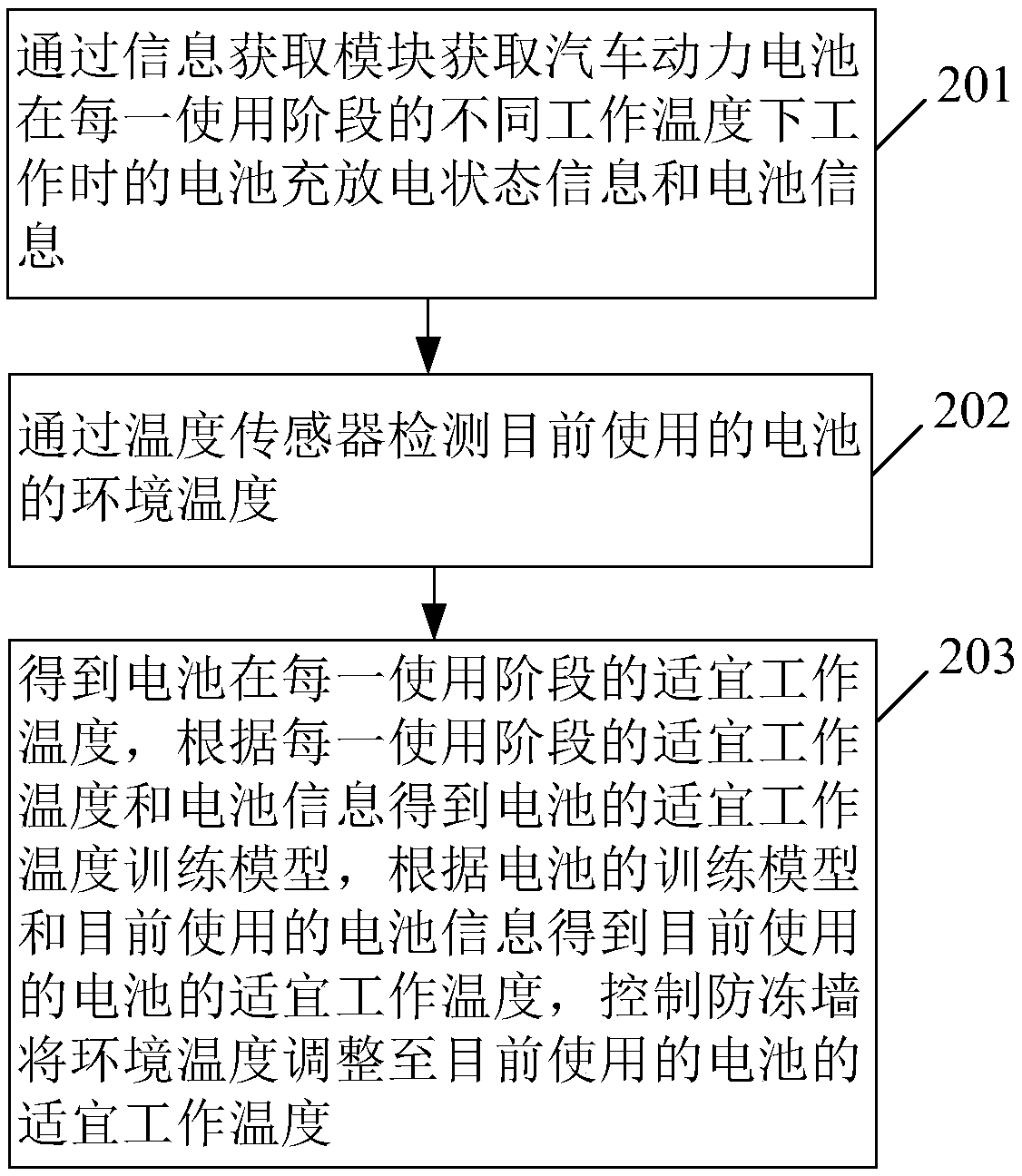

[0047] figure 2 It is a flow chart of the steps of the battery operating temperature control method for electric vehicles provided by the second embodiment of the present invention. The method is applied to the above-mentioned battery operating temperature control device for electric vehicles, please refer to figure 2 , the method for controlling the battery operating temperature of an electric vehicle in this embodiment includes the following steps 201-203.

[0048] Step 201, acquire the battery charge and discharge state information and battery information when the vehicle power battery is working at different operating temperatures in each use stage through the information acquisition module, and provide the acquired battery charge and discharge state information and battery information to the control module;

[0049] Step 202, detecting the ambient temperature of the currently used battery through the temperature sensor, and providing the ambient temperature of the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com