A rubber heating pad with automatic temperature control

A heating pad and rubber technology, applied in the fields of rubber heating pads and automatic temperature control rubber heating pads, can solve the problems of no temperature control, low reliability and service life, combustion, etc., and achieve good insulation, reliability and service life. high effect

Active Publication Date: 2015-08-05

TAIYUAN AERO INSTR

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The rubber heating pad with this structure cannot be completely isolated from the electric heating alloy wire and the pipeline, and the insulation is poor; there is no temperature control, and it is easy to cause combustion due to high temperature, and there are problems of low reliability and service life.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

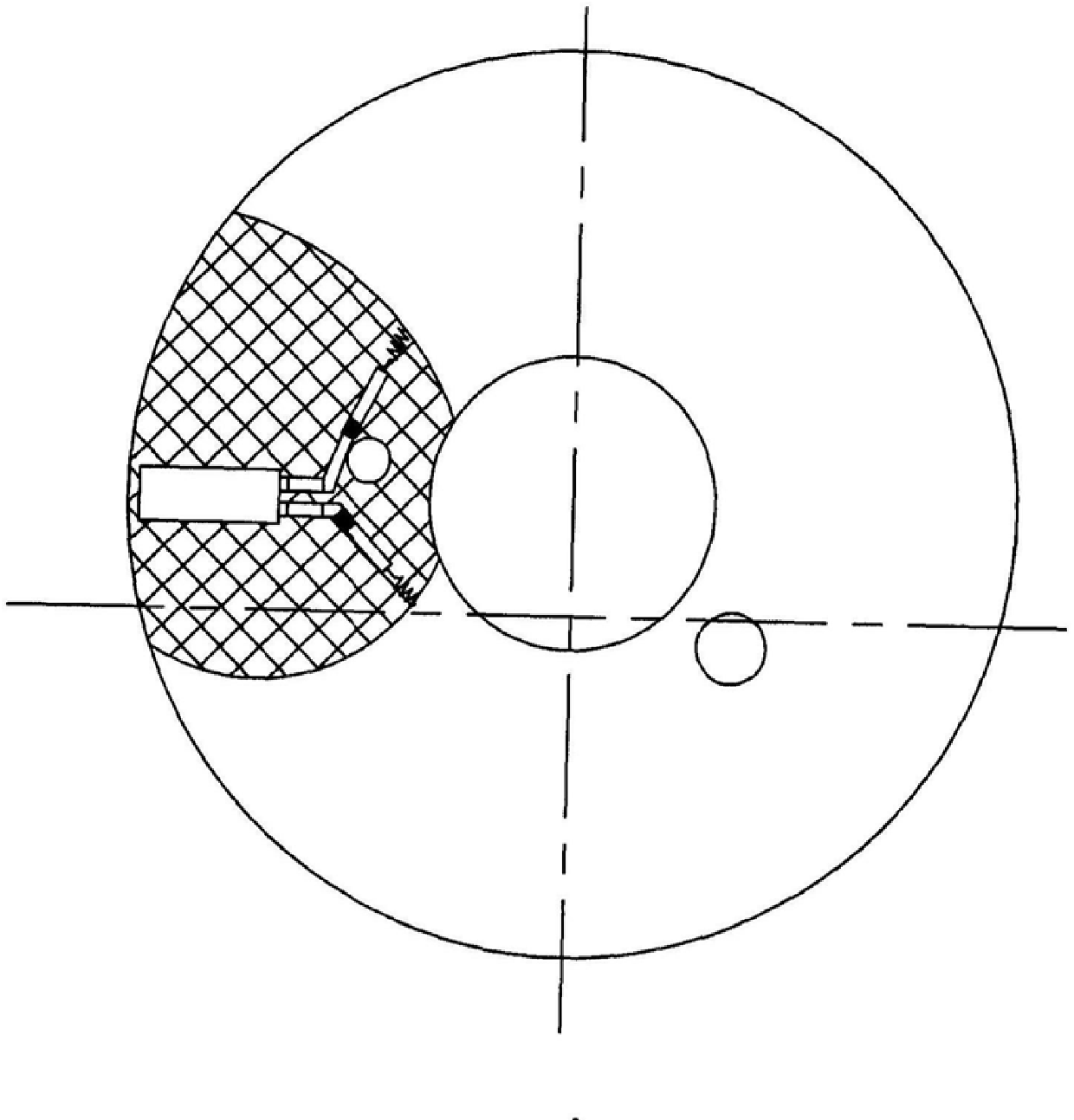

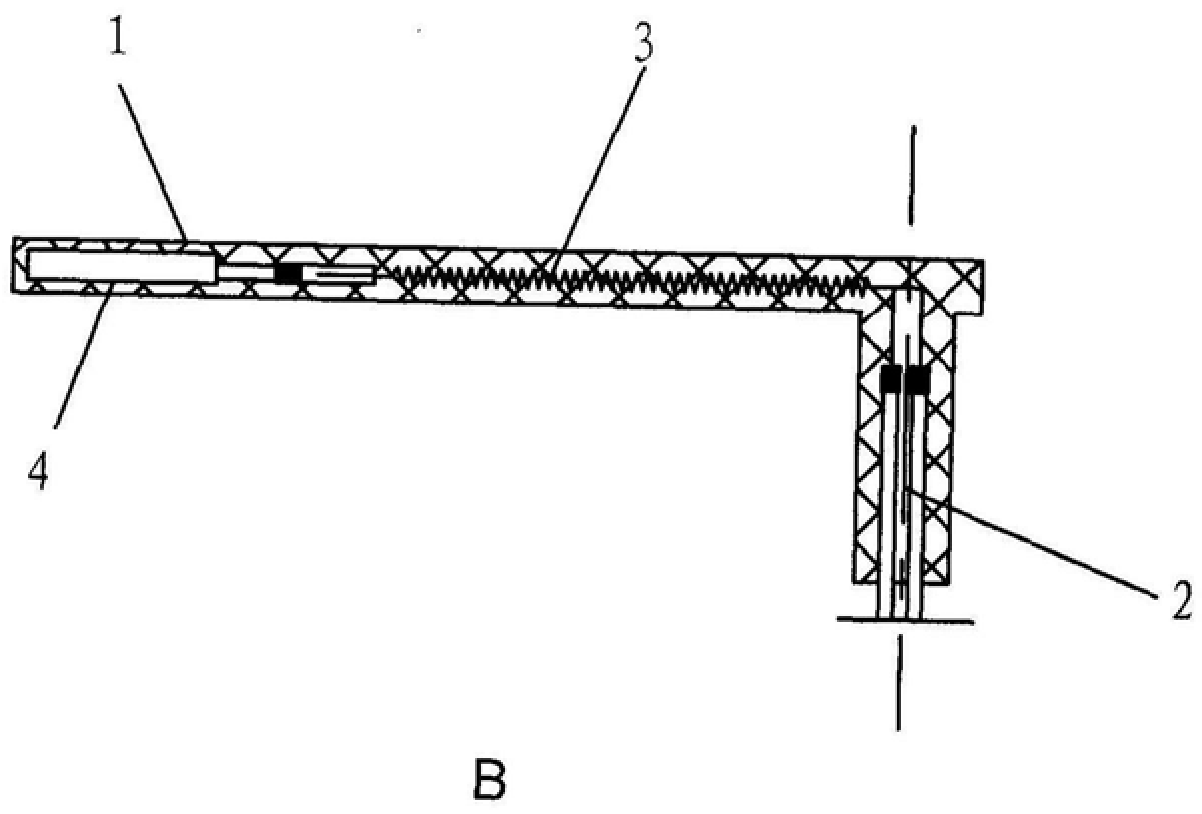

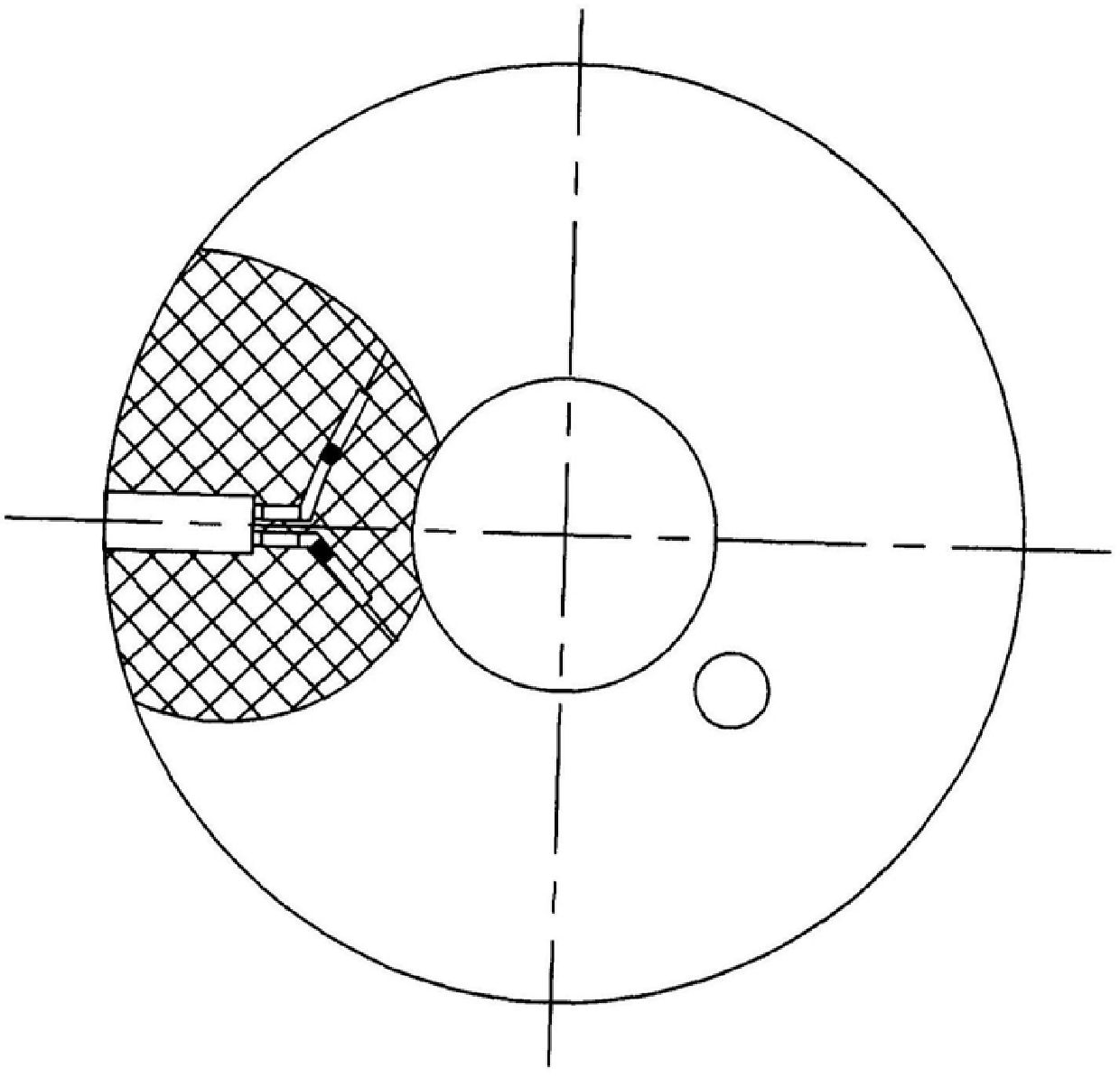

The invention belongs to the airborne equipment technology, and the invention relates to a rubber heating pad used in the water and waste water system of an aircraft, in particular to a rubber heating pad with an automatic temperature control function, that is, an automatic temperature control rubber heating pad. The automatic temperature control rubber heating pad includes rubber seals, electric heating alloy wires, and a thermostat. The electric heating alloy wires and temperature controllers are placed in rubber. Completely isolated, the shape of the electrothermal alloy wire is straight or wound into a spiral state, and the heating circuit is led out by two high temperature resistant wires. The invention is installed in the water filling joint, sewage discharge joint and cleaning joint, which can prevent the water filling joint, sewage discharge joint and cleaning joint from freezing when the aircraft is flying, and the service life can reach 30 years or 30,000 flight hours.

Description

An automatic temperature control rubber heating pad technical field The invention belongs to the airborne equipment technology, and relates to a rubber heating pad used in the water and waste water systems of an aircraft, in particular to a rubber heating pad with automatic temperature control function, that is, an automatic temperature control rubber heating pad. Background technique When the aircraft is flying in the atmosphere, the interface of the water and wastewater system of the aircraft needs to be heated by a rubber heating element to electrically heat the interface of the water and wastewater system, so that the above-mentioned product pipeline interface does not freeze or has the ability to melt ice. If the rubber heating element is not used, the pipeline interface of the water and waste water system of the aircraft will freeze, and in severe cases, the pipeline will be blocked by ice, which will affect the operation of the water and waste water system of the air...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05B3/18F16L9/12

Inventor 庞建君

Owner TAIYUAN AERO INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com