Real-time monitoring system and method of CO2 discharging amount of blast furnace

A technology for real-time monitoring system and emissions, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as non-real-time and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

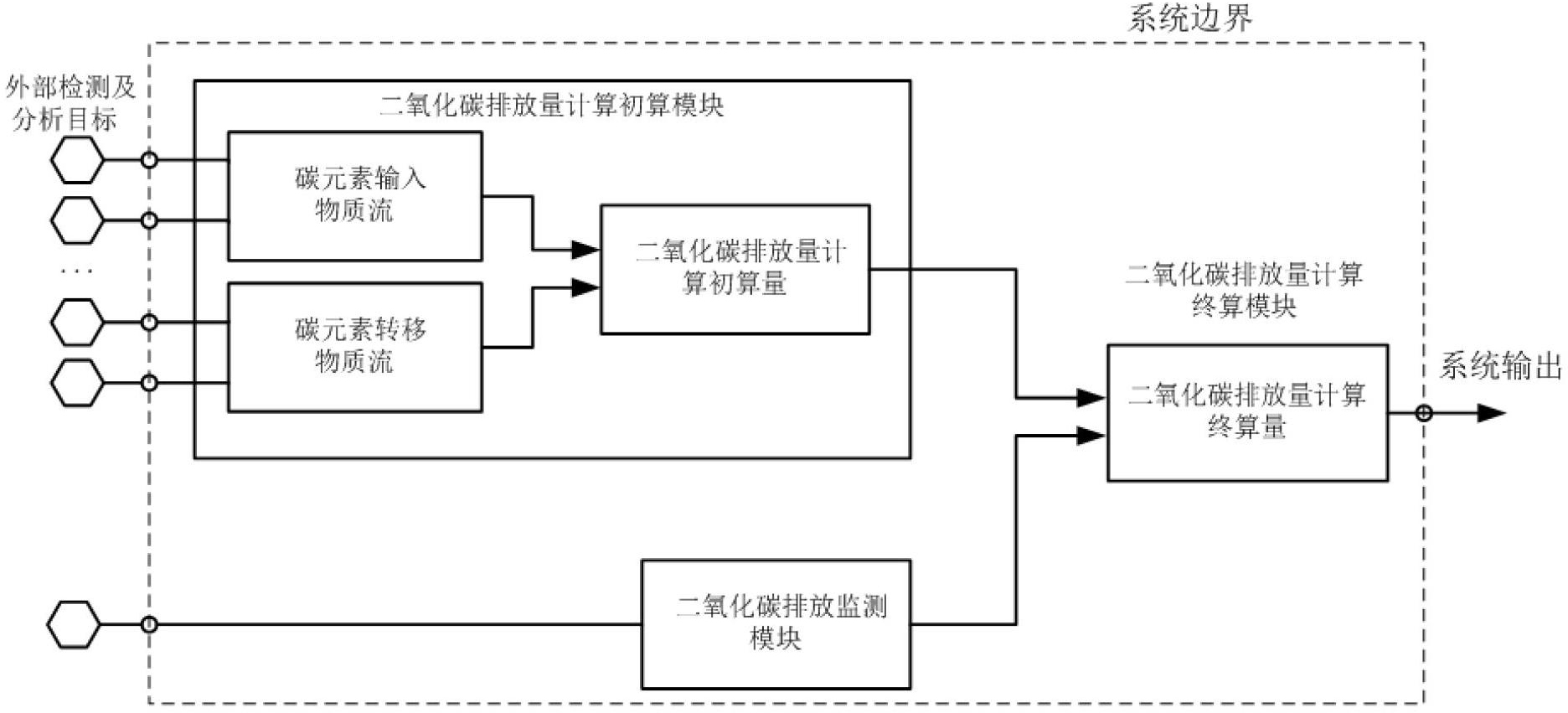

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

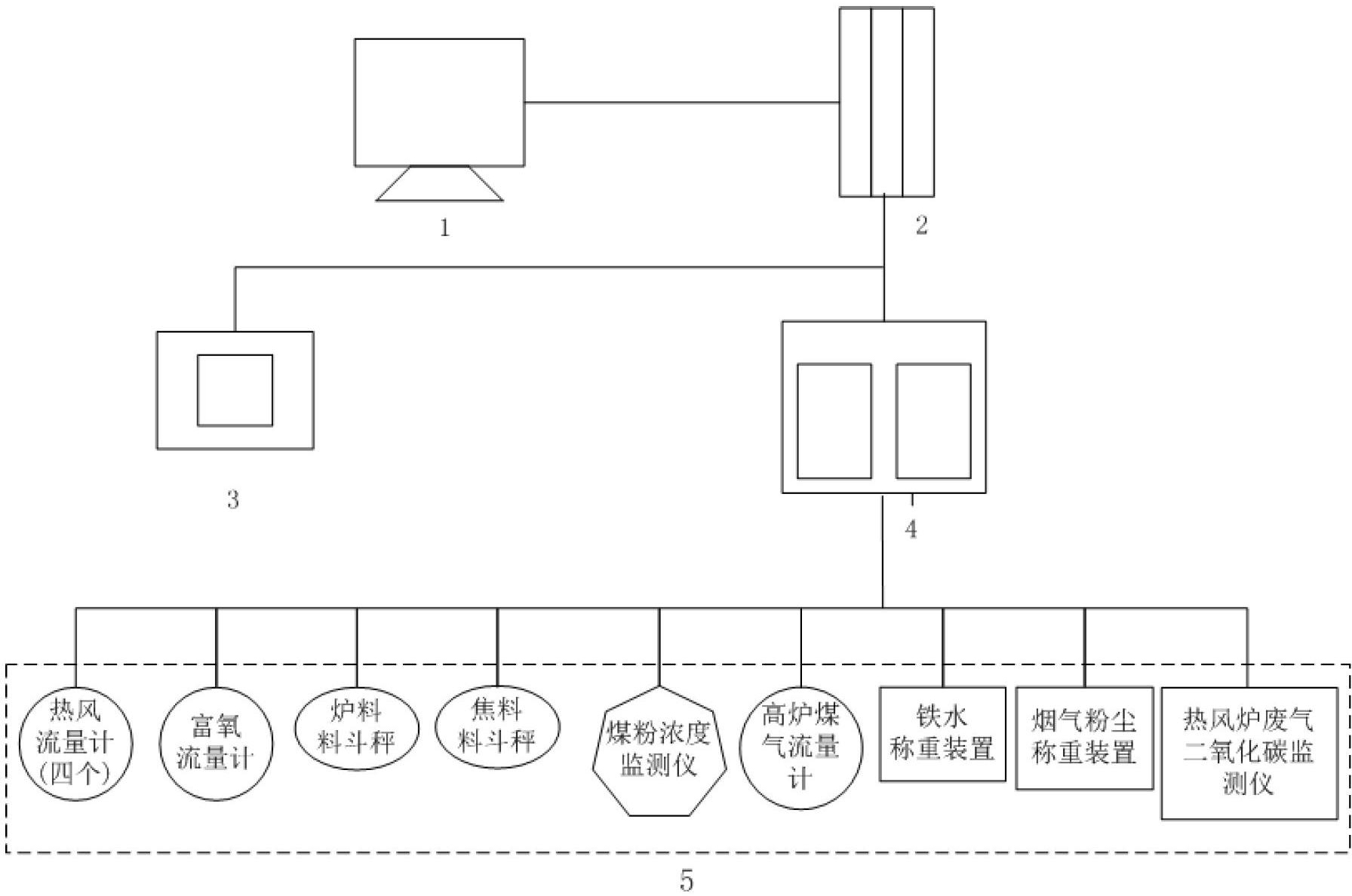

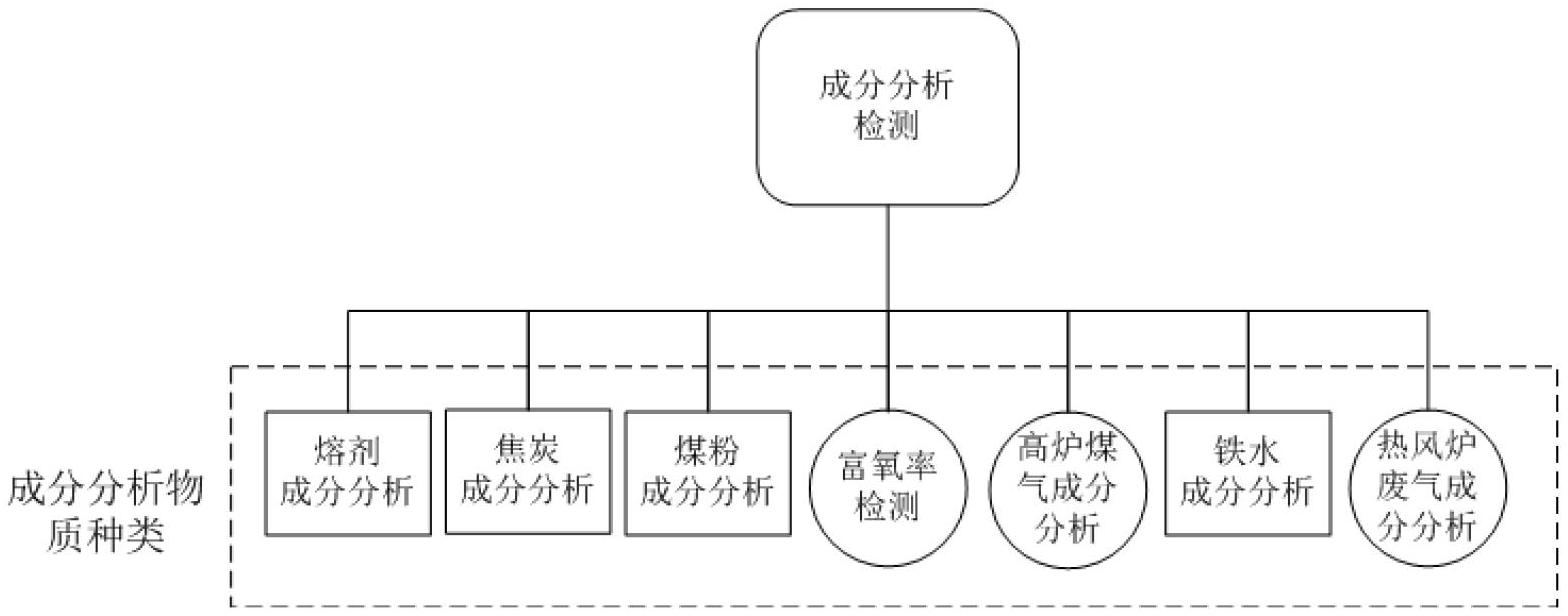

[0076] The real-time monitoring system for blast furnace carbon dioxide emissions involves a large amount of carbon material flow data on the blast furnace system, including real-time material flow and material composition analysis and testing data. The types of materials involved and monitoring equipment such as Figure 5 The material flow and monitoring equipment marked in , are mainly distributed as follows: coke hopper scales and furnace charge hopper scales for weighing incoming coke and materials are installed at the charging port on the top of the blast furnace; At the blast outlet at the location, the substances that are blown include hot air, oxygen-enriched and coal powder. The hot air comes from the alternate air supply of the four hot blast stoves on site, so four hot blast air outlets are installed at the outlet pipes of the four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com