Method for preparing glyphosate

A technology of glyphosate and bisglyphosate, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., to reduce energy consumption, realize automatic control, and reduce reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

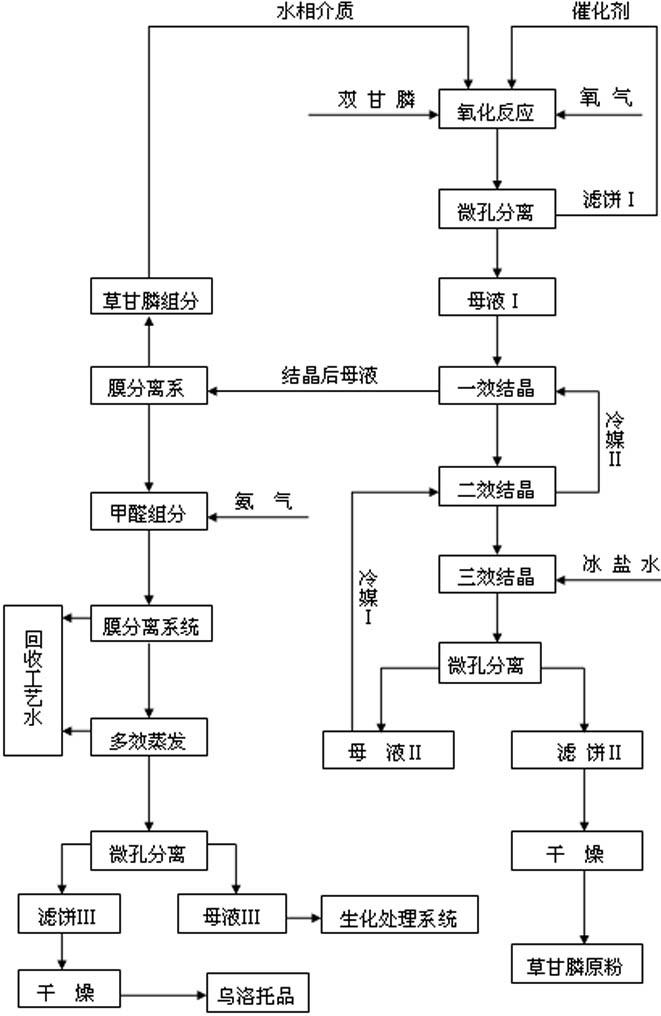

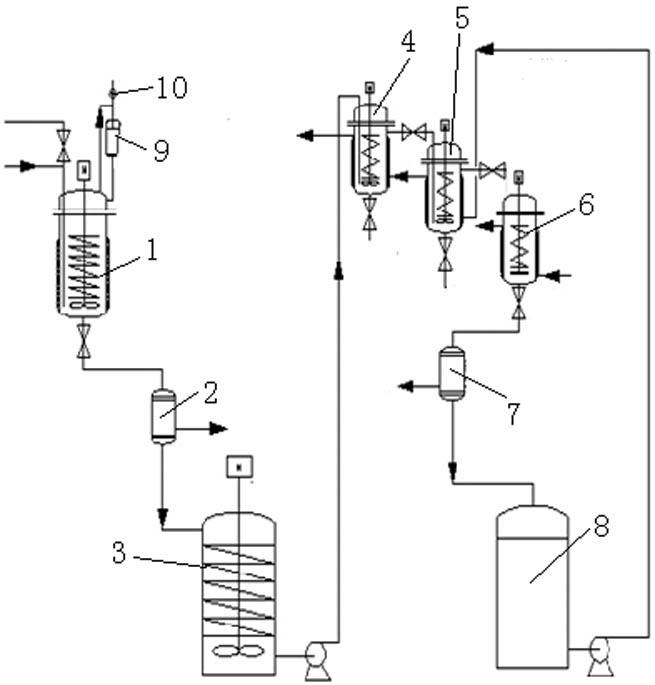

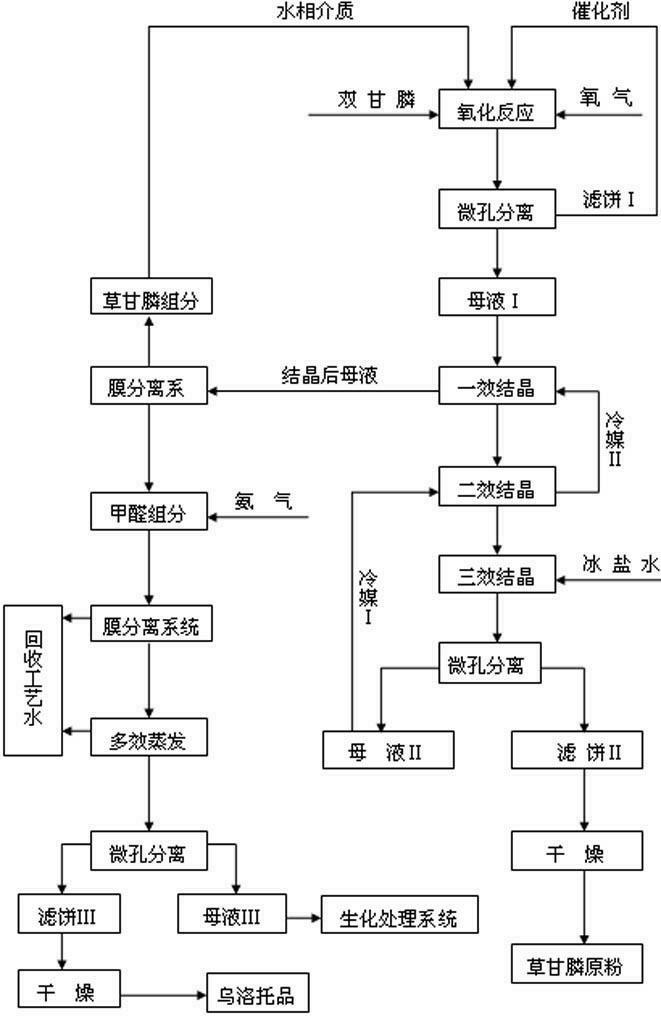

[0038] see figure 1 , figure 2 , 100g of bisglyphosate, 6.6g of activated carbon, and 893g of water were made into a suspension and dropped into the pressure reactor 1. The water is deionized water, the mass fraction of bisglyphosate is greater than 98%, and the specific surface area of activated carbon is 1200m 2 / g. Close the pressure reactor, start stirring, heat, and raise the temperature to 75°C at a stirring speed of 700r / min, feed oxygen at a flow rate of 0.3L / min, control the pressure of the reactor to 0.3MPa, and the reaction time to 90min. Release the pressure to normal pressure, take a sample to detect the diglyphosate, and stop the oxygen flow after the diglyphosate is completely converted. The reaction material is heated to 90° C. and filtered through the first microporous filtration device 2 to obtain filter cake I and mother liquor I. Filter cake I activated carbon was used as a catalyst for the next oxidation reaction. The mass fraction of glyphosate wa...

Embodiment 2

[0041] see figure 1 , figure 2 100g bisglyphosate, 893g water and embodiment 1 reclaim filter cake I activated carbon (add 5% fresh activated carbon of activated carbon consumption percentage in embodiment 1) to be made into suspension, drop in the pressure reaction kettle; Wherein water adopts to remove Ionized water, the mass fraction of bisglyphosate is greater than 98%, and the specific surface area of activated carbon is 1200m 2 / g. Close the pressure reactor, start stirring, heat, and raise the temperature to 75°C at a stirring speed of 700r / min, feed oxygen at a flow rate of 0.3L / min, control the pressure of the reactor to 0.3MPa, and the reaction time to 90min. Release the pressure to normal pressure, take a sample to detect the diglyphosate, and stop the oxygen flow after the diglyphosate is completely converted. The reaction material is heated to 90° C. and then filtered through the first microporous filter device to obtain filter cake I and mother liquor I. ...

Embodiment 3

[0044] see figure 1 , figure 2 , with 100g bisglyphosate, 893g glyphosate crystallization mother liquor (after the mother liquor II of embodiment 1 is used as the refrigerant of embodiment 2) and the recovery filter cake I activated carbon of embodiment 2 (adding 5% of the active carbon consumption percentage in embodiment 2 fresh Activated carbon) is made into a suspension and put into a pressure reactor; the mass fraction of bisglyphosate is greater than 98%, and the specific surface area of activated carbon is 1200 m 2 / g. Close the pressure reactor, start stirring, heat, and control the stirring speed at 700r / min to raise the temperature to 75°C, feed oxygen at a flow rate of 0.3L / min, control the pressure of the reactor to 0.3MPa, and the reaction time to 90min. Release the pressure to normal pressure, take a sample to detect the diglyphosate, and stop the oxygen flow after the diglyphosate is completely converted. The reaction material is heated to 90° C. and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com