Energy-saving and waste-utilizing concrete block or board and production method thereof

A technology for waste blocks and plates, applied in the field of building materials, can solve the problems of low strength, long demoulding time, large capital investment, etc., and achieve the effects of excellent thermal insulation performance, good economic benefits, and good fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

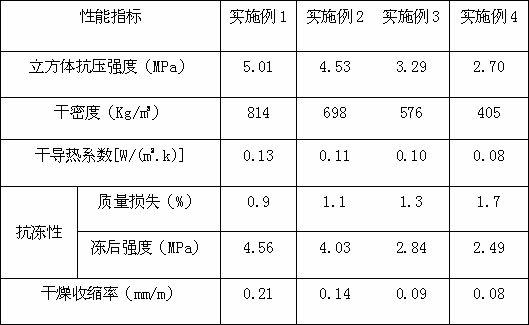

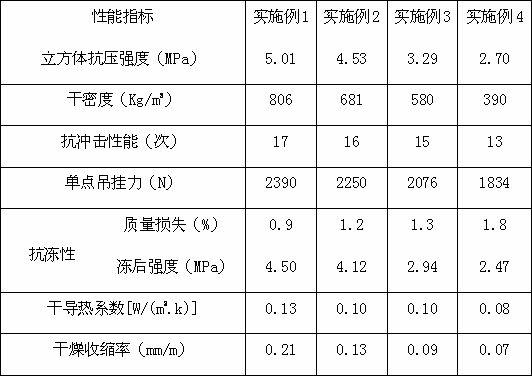

Embodiment 1

[0053] Example 1, an energy-saving and waste-recycling block and plate, according to desulfurization gypsum 100, S95 slag powder 80, superfine fly ash 100, cement 30, foaming agent 0.2, alkaline activator 2, early strength agent 0.5, Water reducer 0.02, mineral fiber 0.35, triethanolamine 0.02 weight ratio prepared. Wherein the foaming agent is dissolved in water equivalent to 150 times its weight. The water consumption for preparing slurry is 45% of the total weight of desulfurized gypsum, slag powder, superfine fly ash and cement. The steam curing system adopted is a static stop temperature of 15°C, a static stop time of 2h, a heating rate of 5°C / h, a constant temperature of 50°C, a constant temperature time of 5h, a cooling rate of 20°C / h, and a cooling target temperature of 15°C. The properties of this energy-saving and waste-recycling block and plate are shown in Table 1 and Table 2, respectively.

Embodiment 2

[0054] Example 2, an energy-saving and waste-recycling block and plate, according to desulfurization gypsum 100, S75 slag powder 90, superfine fly ash 20, cement 55, foaming agent 0.5, alkaline activator 6, early strength agent 4, Water reducer 0.75, mineral fiber 3.50, triethanolamine 0.010 weight ratio prepared. Wherein the foaming agent is dissolved in water equivalent to 150 times its weight. The water consumption for preparing slurry is 50% of the total weight of desulfurized gypsum, slag powder, superfine fly ash and cement. The steam curing system adopted is a static stop temperature of 20 °C, a static stop time of 4 h, a heating rate of 10 °C / h, a constant temperature of 60 °C, a constant temperature time of 8 h, a cooling rate of 25 °C / h, and a cooling target temperature of 20 °C. The properties of this energy-saving and waste-recycling block and plate are shown in Table 1 and Table 2, respectively.

Embodiment 3

[0055] Example 3, an energy-saving and waste-recycling building block and board, according to desulfurization gypsum 100, S75 slag powder 110, superfine fly ash 80, cement 50, foaming agent 0.7, alkaline activator 8, early strength agent 5, Water reducer 0.90, mineral fiber, 1.50, triethanolamine 0.08 weight ratio prepared. Wherein the foaming agent is dissolved in water equivalent to 150 times its weight. The water consumption for preparing the slurry is 55% of the total weight of desulfurized gypsum, slag powder, superfine fly ash and cement. The steam curing system adopted is 25°C static stop temperature, 6h static stop time, 10°C / h heating rate, 65°C constant temperature, 10h constant temperature time, 35°C / h cooling rate, and 20°C cooling target temperature. The properties of this energy-saving and waste-recycling block and plate are shown in Table 1 and Table 2, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com