Preparation method for synchronously cold-rolling iron foil by using laminated method

A lamination method and iron foil technology, applied in the direction of metal rolling, can solve the problems of complex equipment, large investment, and significant rolling process, and achieve the effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

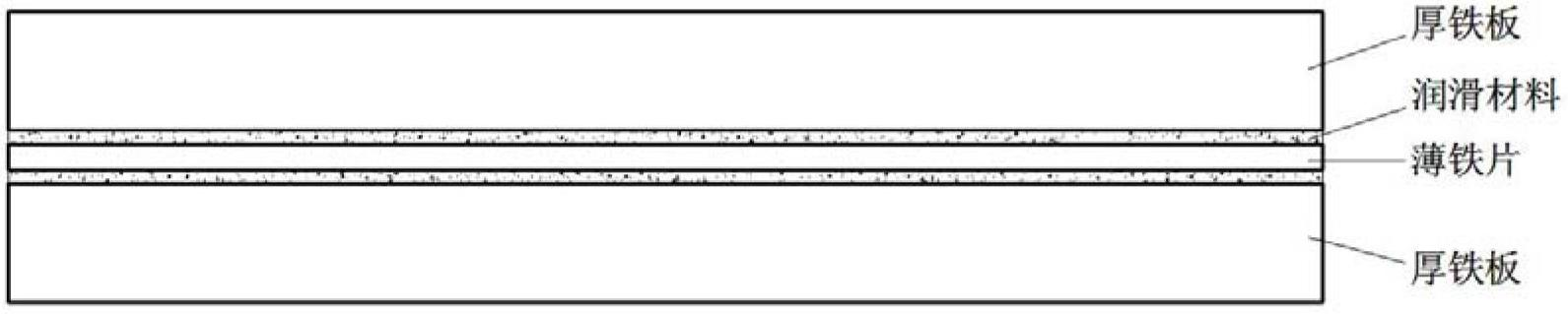

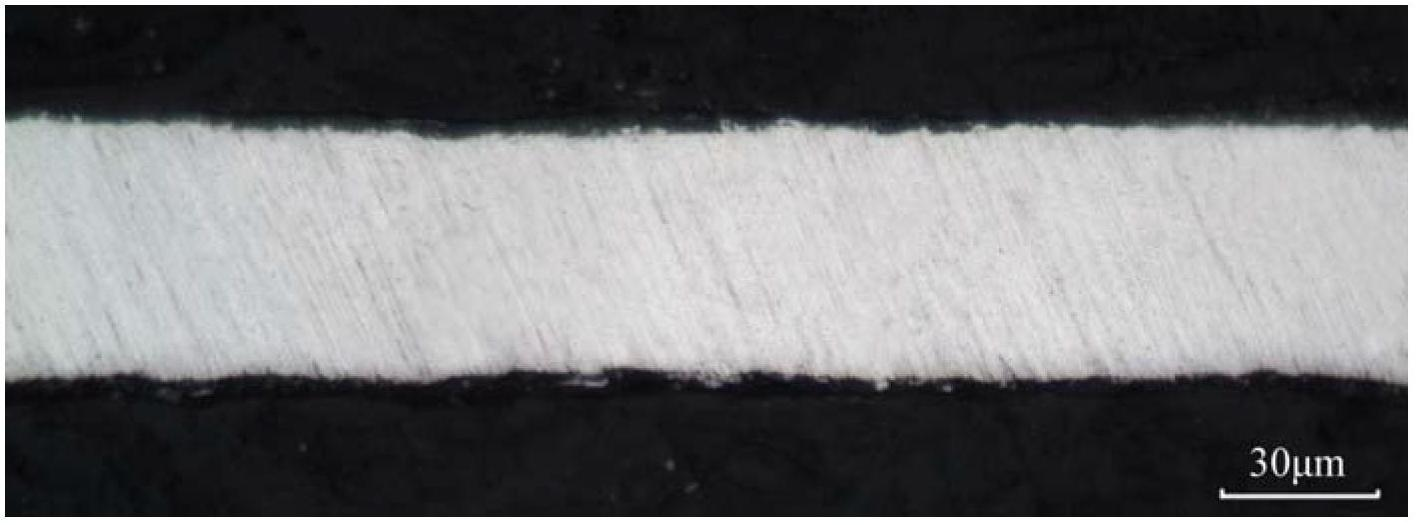

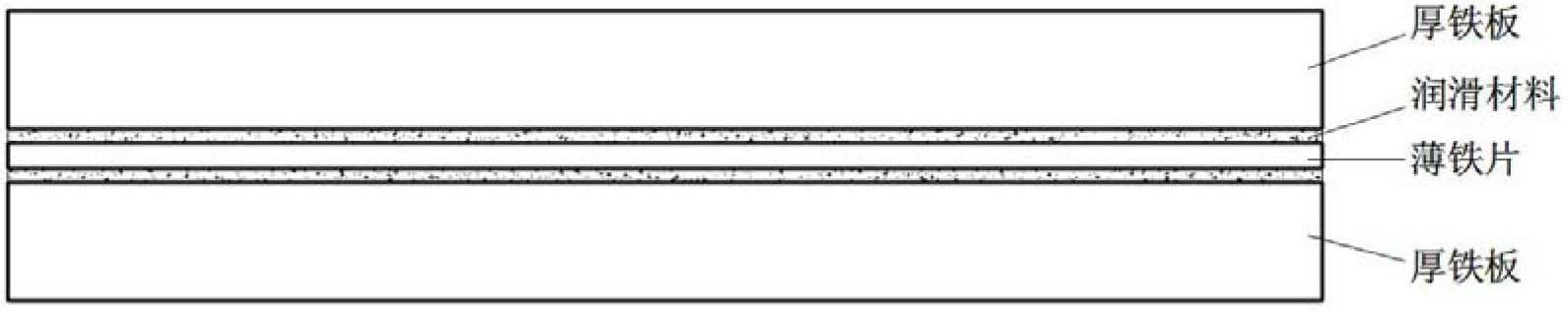

[0026] Select one piece of pure iron with a size of 0.2×100×500mm, and two pieces of pure iron with a size of 4.0×100×500mm; place the 0.2mm thick pure iron piece in a vacuum furnace at 1050°C+10min for recrystallization annealing, 4.0mm The thick pure iron sheet is placed in a vacuum furnace at 500℃+30min for recovery annealing; both sides of the thin iron sheet and one side of the thick iron sheet are polished with 2000 metallographic sandpaper to make the surface roughness reach Ra0.1; Apply graphite on both sides of the sheet, and stack the three pure iron sheets in the order of 4.0 pure iron-0.2 pure iron-4.0 pure iron, and ensure that the laminated contact surface is the surface after bright treatment; riveting the stacked composite sheet head to tail, A two-roll rolling mill is used to carry out two 30% cold rolling reductions; after rolling, the laminated group is untied, and the thin pure iron sheet is taken out. The thickness of the thin iron sheet at this time is abo...

Embodiment 2

[0028] Select one piece of DT4 electrical pure iron with a size of 0.15×100×500mm, and two pieces of DT4 electrical pure iron with a size of 2.0×100×500mm; place the 0.15mm thick electrical pure iron sheet in a vacuum furnace at 950°C+20min for reprocessing Crystallization annealing, 2.0mm thick electrical pure iron sheet is placed in a vacuum furnace at 550°C + 20min for recovery annealing; both sides of the thin iron sheet and one side of the thick iron sheet are treated with a polishing machine to make the surface roughness reach Ra0.05; Then apply extreme pressure lithium-based grease on both sides of the thin iron sheet, and stack the three iron alloy sheets in the order of 2.0 Fe-0.15 Fe-2.0 Fe, and ensure that the contact surface of the stack is the surface after bright treatment; combine the stacks For head and tail riveting, a four-roll mill is used to carry out two 20% cold rolling reductions; after rolling, the laminated group is untied, and the thin pure iron sheet ...

Embodiment 3

[0030] Select one piece of iron-nickel alloy with a size of 0.25×100×500mm, and two pieces of iron-nickel alloy with a size of 1.0×100×500mm; place the 0.25mm thick iron-nickel alloy piece in a vacuum furnace at 850°C+60min for recrystallization annealing, 1.0 mm thick iron alloy sheets are placed in a vacuum furnace at 600°C + 20min for recovery annealing; before stacking, a smooth cold rolling mill is used to cold-roll the thick and thin iron sheets at a reduction rate of 20% to make the iron and nickel Roll out a smooth surface with a roughness better than Ra1.6 on both sides of the alloy; then apply graphite on both sides of the thin iron sheet, and stack the three iron-nickel alloy sheets in the order of 1.0 Fe-0.25 Fe-1.0 Fe; combine the stacks The four corners of the sheet are bonded with 502 glue, and the four-roll mill is used to carry out two cold rolling reductions of 35%; after rolling, the laminated group is untied, and the thin pure iron sheet is taken out. 100 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com