Production process of microwave-cooked dumplings

A production process, dumpling technology, which is applied in the field of microwave dumpling production process, can solve the problems of flavor and nutritional deficiency, product taste decline, etc., and achieve the effect of being easy to eat, smooth and delicate in taste, and having a broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

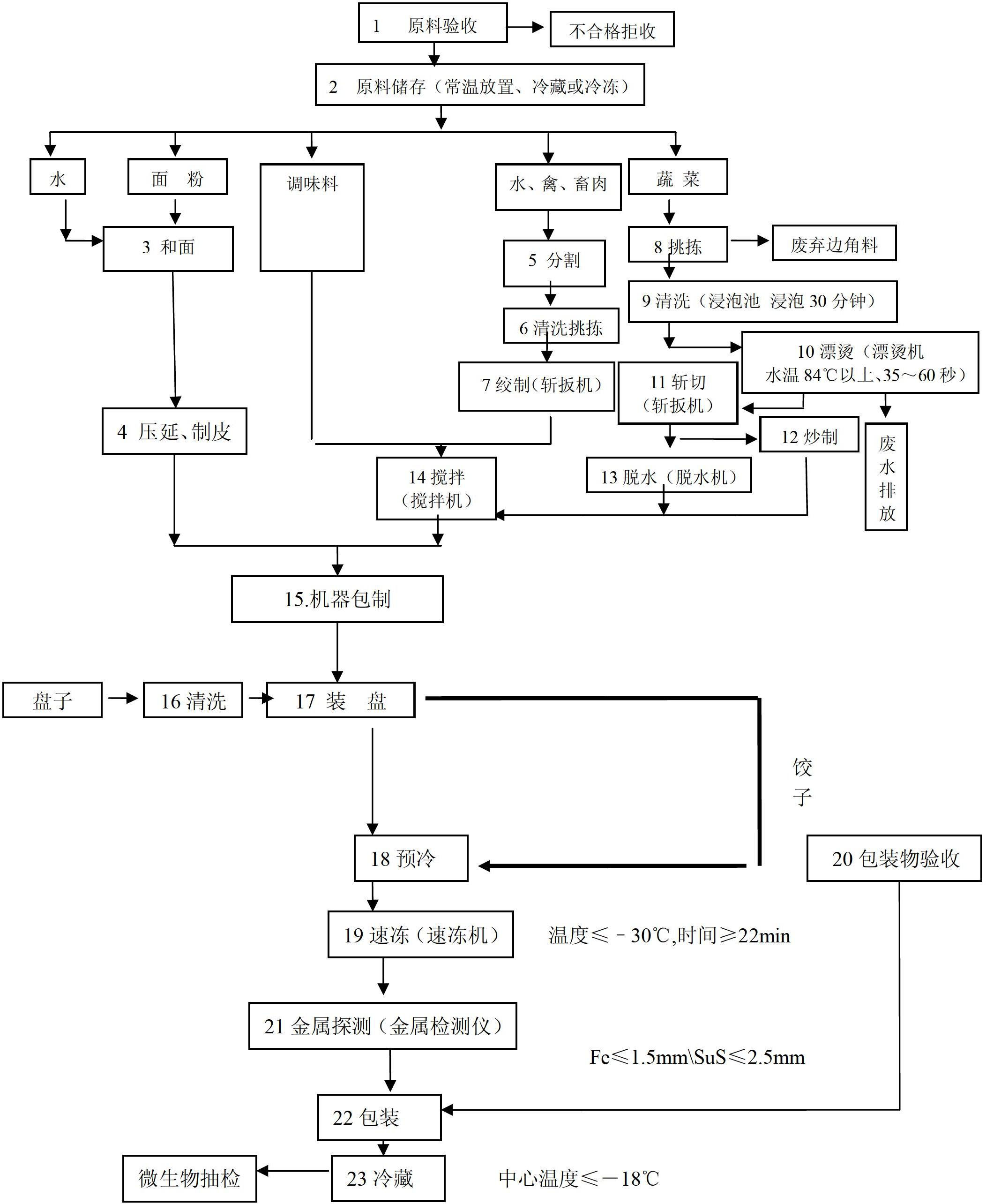

Image

Examples

Embodiment 1

[0023] The production technology of making microwave boiled dumplings comprises:

[0024] 1) Kneading dough: Weigh 10kg of flour, add 20g of salt to the flour, then take 3.3kg of normal temperature water and the above flour at room temperature and use a vacuum dough kneading machine to knead the dough. The kneading time is 18 minutes; no need to scald the dough;

[0025] 2) Mix stuffing: Take 135g of salt, 15g of chicken essence, 77.5g of monosodium glutamate, 200g of light soy sauce, 40g of soft white sugar, 100g of rice wine, 150g of chives, and 62.5g of ginger, mix and stir to make 0.78kg of seasoning; clean and pick fresh meat Use a chopping machine to mince meat; soak the picked vegetables for 20 minutes, then blanch the washed and soaked vegetables at a temperature of 85°C for 35 seconds, then drain the blanched vegetables Finally, chop and pulverize, and finally carry out dehydration treatment; weigh 5kg of meat stuffing, then add 4kg of crushed and dehydrated vegetable...

Embodiment 2

[0031] The production technology of making microwave boiled dumplings comprises:

[0032] 1) Kneading dough: Weigh 20kg of flour, add 40g of salt to the flour, then take 6.6kg of normal temperature water and the above flour at room temperature and use a vacuum dough kneading machine to knead the dough. The kneading time is 19 minutes; no need to scald the dough;

[0033] 2) Mix stuffing: Take 270g of salt, 30g of chicken essence, 155g of monosodium glutamate, 400g of light soy sauce, 80g of soft white sugar, 200g of rice wine, 300g of chives, and 125g of ginger, mix and stir to make 1.56kg of seasoning; clean and pick fresh meat with chopped Mixing machine to make meat stuffing; Soak the picked vegetables for 25 minutes, then blanch the washed and soaked vegetables, the blanching temperature is 87°C, and the blanching time is 45 seconds, then drain the blanched vegetables and chop them Cut and pulverize, and finally carry out dehydration treatment; weigh 10kg of minced meat, t...

Embodiment 3

[0039] The production technology of making microwave boiled dumplings comprises:

[0040] 1) Kneading dough: Weigh 20kg of flour, add 40g of salt to the flour, then take 6.4kg of normal temperature water and the above-mentioned flour at room temperature and use a vacuum dough kneading machine to knead the dough. The kneading time is 20 minutes; no need to scald the dough;

[0041] 2) Mix stuffing: Take 280g of salt, 40g of chicken essence, 160g of monosodium glutamate, 450g of light soy sauce, 90g of soft white sugar, 250g of rice wine, 350g of chives, and 126g of ginger, mix and stir to prepare 1.746kg of seasoning; clean and pick fresh meat with chopped Mixing machine to make meat stuffing; Soak the picked vegetables for 30 minutes, then blanch the washed and soaked vegetables, the blanching temperature is 89°C, and the blanching time is 60 seconds, then drain the blanched vegetables and chop Cut and pulverize, and finally carry out dehydration treatment; weigh 10kg of mince...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com