Lithium titanate negative electrode material and preparation method thereof

A negative electrode material, lithium titanate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low tap density and low volume specific energy density of lithium-ion batteries, and achieve the effect of high volume specific energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

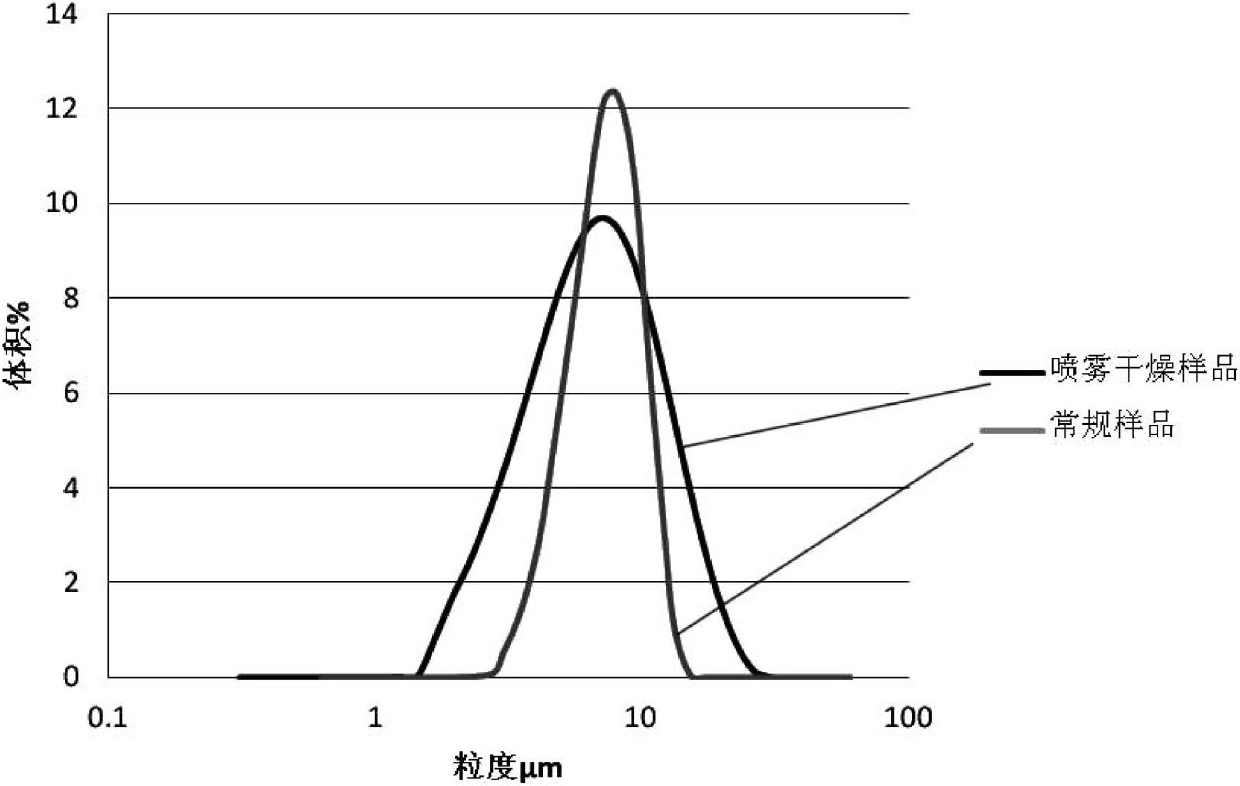

[0019] The invention provides a preparation method of lithium titanate negative electrode material, which specifically comprises the following steps: making LiOH·H 2 O and TiO 2 Add in a molar ratio of 0.7~0.9:1, mix well to obtain the first material; add deionized water to the first material at a solid-to-liquid volume ratio of 3:1, and pulverize into a suspended second material; dry the second material to obtain Precursor; sintering the precursor at 600-900° C. for 5-20 hours to obtain a third material; sieving the third material with 400 meshes to obtain a lithium titanate negative electrode material, the lithium titanate negative electrode material being spherical.

[0020] In the step of drying the second material to obtain the precursor, the second material is spray-dried to obtain a spherical precursor.

[0021] Since the spherical precursor has a higher density than other loose particles, the obtained lithium titanate negative electrode material has a higher tap densi...

Embodiment 1

[0036] LiOH·H 2 O and TiO 2Weigh at a molar ratio of 0.812:1; add the above-mentioned weighed raw materials and appropriate amount of deionized water into a wet pulverizer to pulverize into powder; then carry out spray drying, adjust the feed pump frequency to 34Hz, feed speed The drying temperature was set at 7.5kg / hr, and the drying temperature was set at 170°C to obtain the precursor; the precursor was sintered at a high temperature, the high temperature sintering temperature was controlled at 700°C, and the sintering time was controlled at 20 hours; after sintering and cooling, 400-mesh sieve was carried out. Finally, lithium titanate negative electrode materials with particle sizes of D50=8 μm, D10=4 μm, and D90=20 μm were obtained.

[0037] Test results of charge and discharge experiments: figure 2 As shown, the lithium titanate negative electrode material in Example 1 is made into a battery and then charged and discharged. The results show that the discharge capacity...

Embodiment 2

[0041] LiOH·H 2 O and TiO 2 Weigh according to the molar ratio of 0.7:1; add the above-mentioned weighed raw materials and appropriate amount of deionized water into a wet pulverizer to pulverize into powder; then carry out spray drying, adjust the feed pump frequency to 30Hz, feed speed The drying temperature is 7kg / hr, and the drying temperature is set at 150°C to obtain a lithium titanate precursor; the lithium titanate precursor is sintered at a high temperature, the high temperature sintering temperature is controlled at 600°C, and the sintering time is controlled at 20 hours; after sintering and cooling, the product is then A 400-mesh sieve was carried out to finally obtain lithium titanate negative electrode materials with particle sizes of D50=6 μm, D10=1 μm, and D90=10 μm.

[0042] Test results of charge and discharge experiments: The lithium titanate negative electrode material in Example 2 was made into a battery and then charged and discharged. The results showed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com