Device for recycling organic entrained spent acid extracted through wet process and recycling method by using recycling device

A recovery device and organic technology, applied in the field of wet extraction organic entrained residual acid recovery device, can solve problems such as waste, increased input costs, and impact on product quality, so as to reduce production costs, improve product quality, and reduce acid ammonia consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

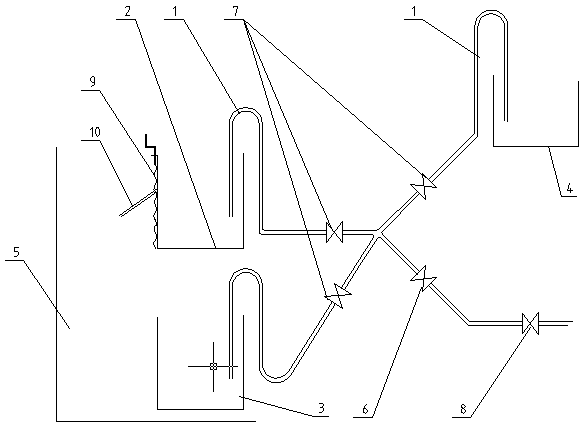

[0011] Example 1 as figure 1 Shown: A recovery device for organic entrained residual acid by wet extraction, the main tank 5 in the extraction, separation and smelting includes a multi-stage clarification chamber 2 and a mixing chamber 3; Bucket 4 and main tank 5, the clarification chamber 2 of the last stage, mixing chamber 3, blank organic turnover tank 4 and main tank 5 communicate with each other through siphon 1; The siphon pipe 1 is introduced into the clarification chamber 2, and then enters the main tank 5 through the water phase overflow port of the clarification chamber 2 itself, and the liquid level height of each part is the same; the water phase overflow port 10 of the final stage main tank clarification chamber 2 is connected to The screw screw 9 is connected, and the rotation of the screw screw 9 can adjust the height of the water phase overflow of the last stage clarification chamber 2 of the main body tank, thereby controlling the height of residual acid allow...

Embodiment 2

[0013] Example 2 as figure 1 As shown: the method for recovering residual acid entrained by wet extraction using the recovery device described in Example 1, including: the clarification chamber 2, the mixing chamber 3, and the blank organic turnover barrel 4 of the last stage in the extraction, separation and smelting are connected to each other through a siphon 1 ; The residual acid of the blank organic turnover barrel 4 and the mixing chamber 3 is introduced into the clarification chamber 2 through the siphon 1, and then enters the main tank 5 through the water phase overflow port of the clarification chamber 2 self, and the liquid level height of each position is the same; finally The water phase overflow port 10 of the clarification chamber 2 of the primary main tank is connected to the screw screw 9, and the rotation of the screw screw 9 can adjust the height of the water phase overflow port 10 of the clarification chamber 2 of the main tank, thereby controlling the allowa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com