Plastic particle filter

A technology of plastic particles and filters, applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc., can solve the problems of easy blockage of filters, inability to work continuously, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

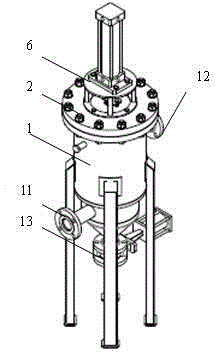

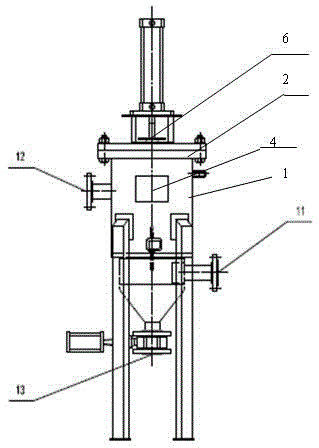

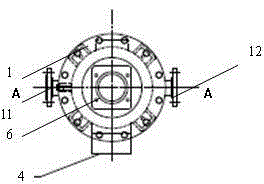

[0030] Attached figure 1 Schematic diagram of the three-dimensional structure of the present invention, attached figure 2 The present invention's main view schematic diagram, appended image 3 top view diagram and attached Figure 4 image 3 The A-A sectional schematic diagram shows:

[0031] A plastic particle filter of the present invention comprises a filter cartridge 1, an upper cover 2 arranged on the top of the filter cartridge 1, a wedge-shaped mesh filter element 3 arranged in the filter cartridge 1, and a liquid inlet 11 is arranged on the side of the filter cartridge 1, A liquid outlet 12 is provided on the upper side, and a slag discharge port 13 is provided at the bottom of the filter cartridge, which is controlled by the PLC controller 4, wherein: a liquid inlet valve is provided at the liquid inlet 12, and a slag discharge valve is provided at the slag discharge port 13, The liquid inlet valve and slag discharge valve are controlled by the PLC controller 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com