Method for extracting muramidase from egg white

A technology of egg white and lysozyme, applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of long production cycle, unsatisfactory product quality, high production cost, etc., and achieve improved stability, convenient recycling, and increased content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

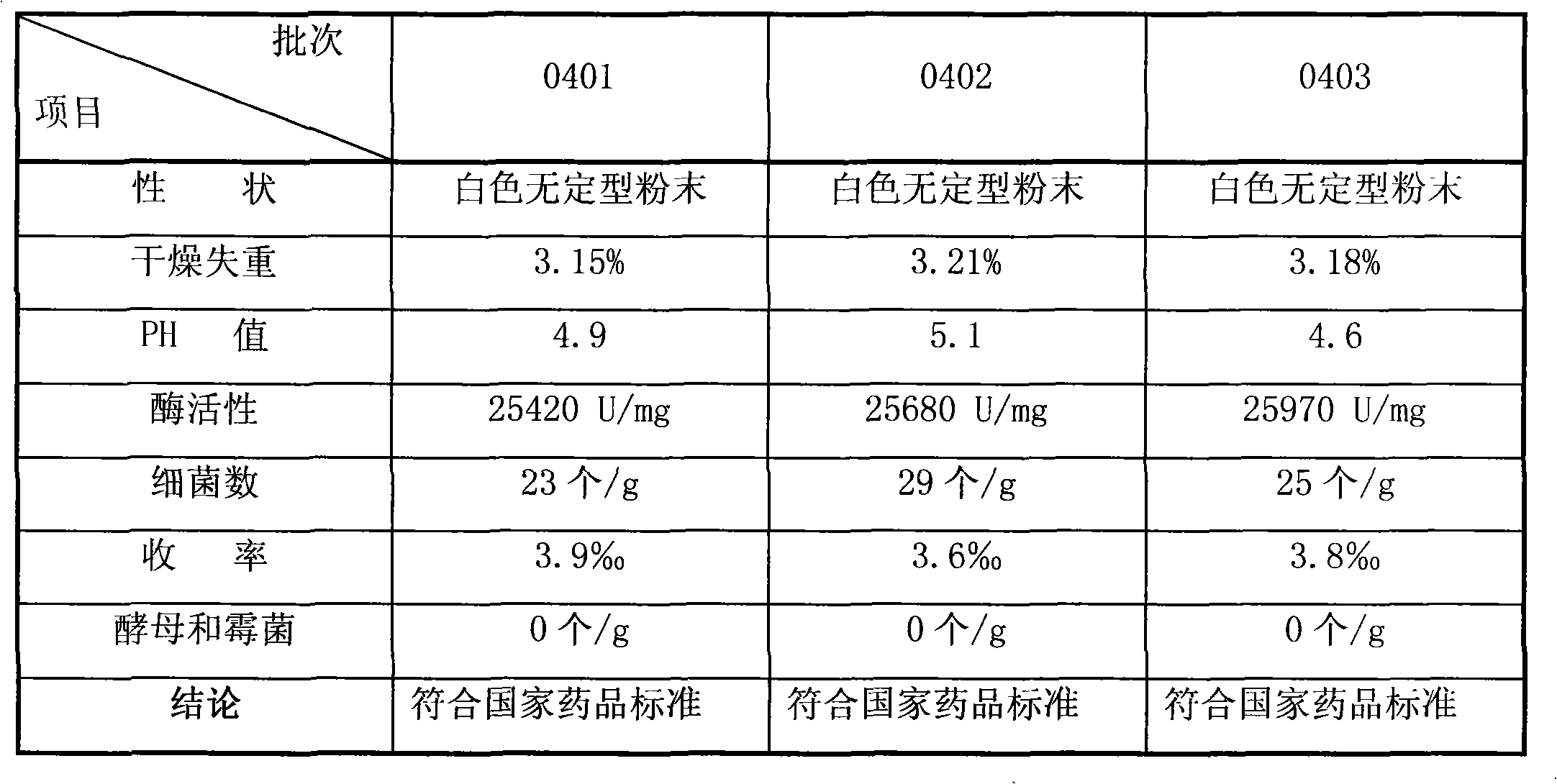

Examples

Embodiment 1

[0039] A method for extracting lysozyme from egg whites, comprising the steps of:

[0040] (1) Preparation of extract:

[0041] Take 1000g of deionized water, adjust the pH value to 3 with lactic acid, then add 50g of sodium chloride, stir and dissolve, and make an extract with a mass percentage of sodium chloride of 5%;

[0042] (2) Selective precipitation of lysozyme:

[0043] The extract obtained in step (1) is subjected to the isoelectric point and temperature selective precipitation of egg white miscellaneous proteins. First, the extract is heated to 90° C., and then 1000 g of egg white liquid is added while stirring, stirred and mixed evenly, and lactic acid is used to control the concentration of the mixed liquid. If the pH value is less than 4.5, and the temperature is controlled at 80°C-85°C, an obvious white flocculent precipitate will appear, keep it warm for 45 minutes to make the precipitate fully;

[0044] (3) separation and purification:

[0045] Cool the mix...

Embodiment 2

[0051] A method for extracting lysozyme from egg whites, comprising the steps of:

[0052] (1) Preparation of extract:

[0053] Take 1000g of deionized water, adjust the pH value to 5 with lactic acid, then add 10g of sodium chloride, stir and dissolve, and make an extract with a mass percentage of sodium chloride of 1%;

[0054] (2) Selective precipitation of lysozyme:

[0055] The extract obtained in step (1) is subjected to the isoelectric point and temperature selective precipitation of egg white miscellaneous proteins. First, the extract is heated to 60° C., and then 500 g of egg white liquid is added while stirring, stirred and mixed evenly, and lactic acid is used to control the concentration of the mixed liquid. If the pH value is less than 4.5, and the temperature is controlled at 60°C-65°C, an obvious white flocculent precipitate will appear, keep it warm for 30 minutes to make the precipitate fully;

[0056] (3) separation and purification:

[0057] Cool the mixe...

Embodiment 3

[0063] A method for extracting lysozyme from egg whites, comprising the steps of:

[0064] (1) Preparation of extract:

[0065] Take 1000g of deionized water, adjust the pH value to 2 with lactic acid, then add 40g of sodium chloride, stir and dissolve, and make an extract with a mass percentage of sodium chloride of 4%;

[0066] (2) Selective precipitation of lysozyme:

[0067] The extract obtained in step (1) is subjected to the isoelectric point and temperature selective precipitation of egg white miscellaneous proteins. First, the extract is heated to 80° C., and then 750 g of egg white liquid is added while stirring, stirred and mixed evenly, and lactic acid is used to control the concentration of the mixed liquid. If the pH value is less than 4.5, and the temperature is controlled at 80°C-85°C, an obvious white flocculent precipitate will appear, keep it warm for 15 minutes to make the precipitate fully;

[0068] (3) separation and purification:

[0069] Cool the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com