Vacuum distillation method for improving distillate yield

A distillation method and vacuum distillation column technology, applied in the field of vacuum distillation, can solve the problems of reduced pressure drop in the oil transfer line, no plug flow, restriction, etc., to prevent cracking and coking, shorten residence time, and simple vaporization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 illustrates the effect of the vacuum distillation method provided by the present invention.

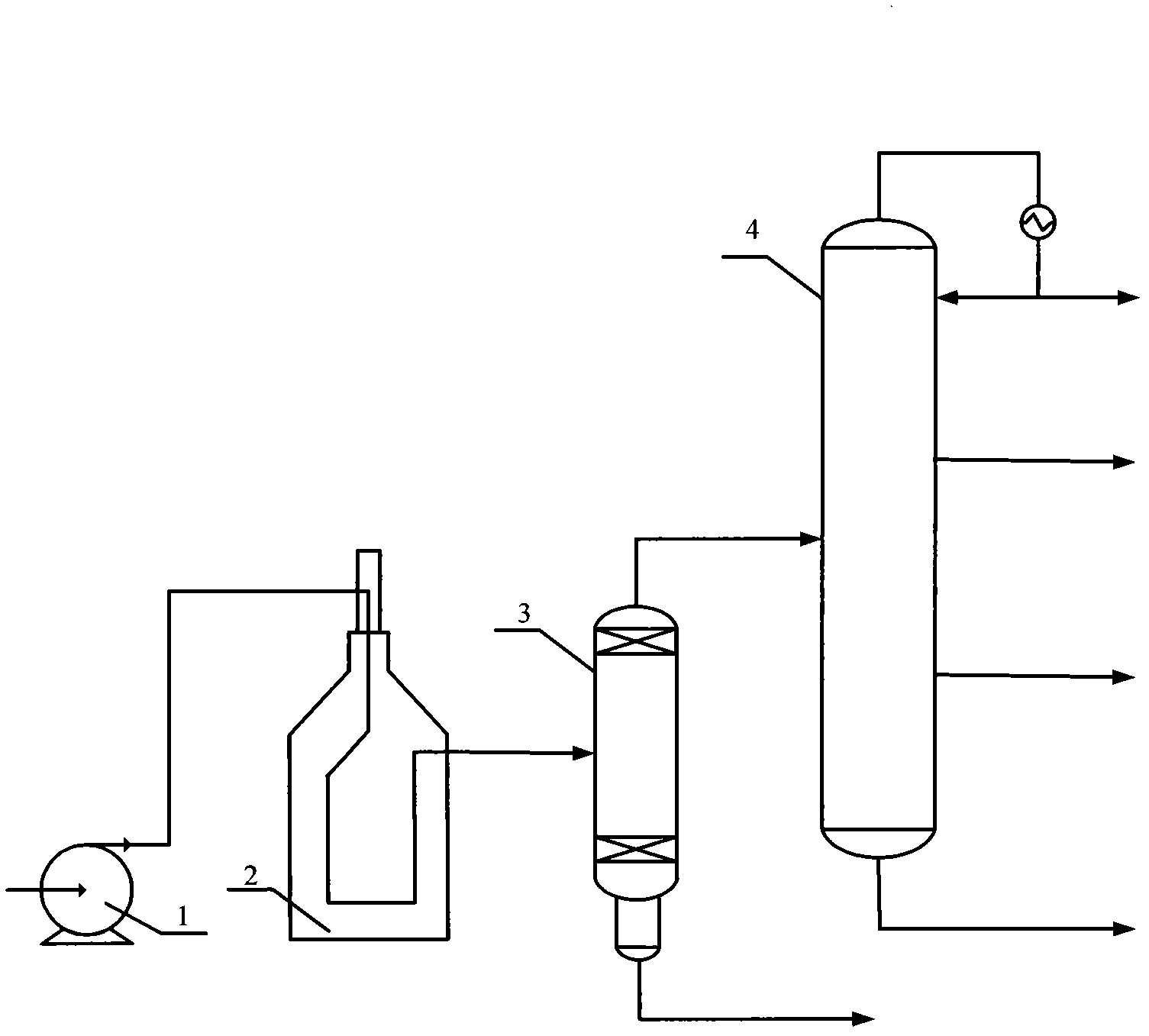

[0034] Process such as figure 1 As shown, the residual oil at 350°C is pressurized by the pump 1 and then enters the decompression furnace 2. After being heated to a tower inlet temperature of 395°C, it enters the intermediate vaporization tower 3. The diameter of the vaporization tower is 1.2 of the diameter of the decompression tower. times, the bottom of the vaporization tower is 6 solid-valve trays, the opening ratio of the trays is 8%, the top of the tower is equipped with a wire mesh demister, the pressure of the vaporization tower is 8kPa, and the load of the heating furnace is 228MJ / t of raw materials. The temperature drop from the furnace outlet to the vaporization tower is 8°C. In the vaporization tower, the light component flashes into a vapor phase and enters the vacuum tower 4 to separate the vacuum distillate oil. The pressure at the top of the vacuum tow...

Embodiment 2

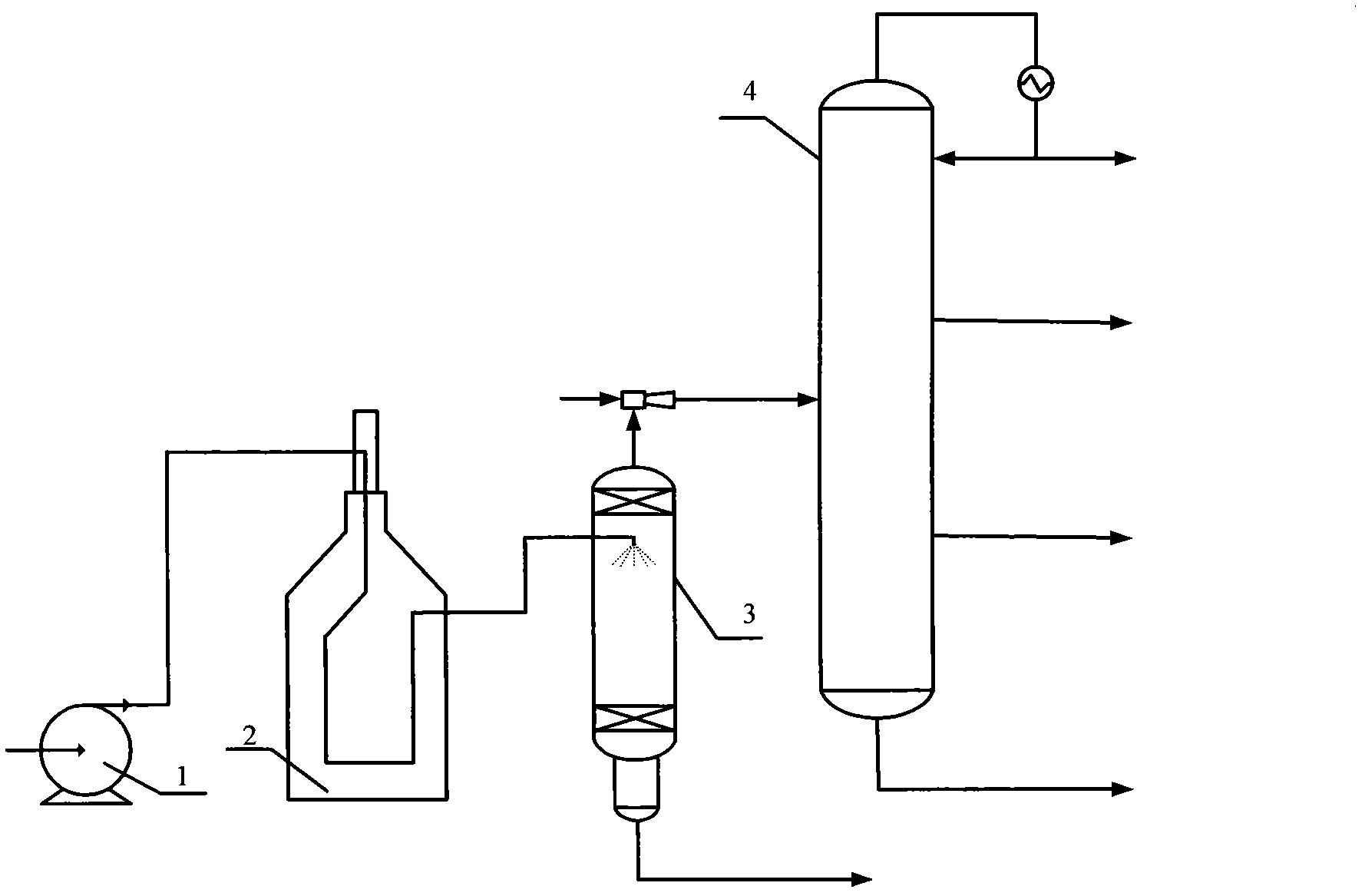

[0036] Example 2 illustrates the effect of the vacuum distillation method provided by the present invention on the vaporization process in the atomization enhanced vaporization tower.

[0037] Process such as figure 2 As shown: 350°C normal-pressure residual oil enters the decompression furnace 2 after being pressurized by the pump 1, and enters the intermediate vaporization tower 3 after being heated to a tower inlet temperature of 430°C to complete the atomization and vaporization process. The diameter of the vaporization tower is reduced 0.8 times the diameter of the pressure tower, the bottom of the vaporization tower is a high-flux grid packing, the height of the packing is 1.2m, the top of the tower is equipped with a wire mesh demister, the pressure before the entrance of the vaporization tower is 500kPa, and the load of the heating furnace is 233MJ / t raw material, the temperature drop from the outlet of the heating furnace to the vaporization tower is 4°C, and the at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com