Dithiocarbamic acid (DTC) modified chitosan macromolecule composite membrane and preparation method

A polymer and chitosan technology, applied in chemical instruments and methods, water/sludge/sewage treatment, coating, etc., can solve problems such as low mechanical strength, and achieve easy regeneration, simple operation, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: DTC chitosan / polyethersulfone composite membrane

[0017] 2.5 g of chitosan with a deacetylation degree of 90% was dissolved in 1 wt % acetic acid solution to obtain a 1 wt % chitosan acetic acid aqueous solution. Filter to remove insoluble impurities, stand to remove air bubbles, mix with 0.12wt% glutaraldehyde aqueous solution at a mass ratio of 5:1, and evenly coat the outer surface of the polyethersulfone membrane with an average coating thickness of 0.1 μm at 60°C The film was cured for 1 h, and finally rinsed with deionized water to remove residual glutaraldehyde. Then the membrane was immersed in 0.2mol / L KHCO 3 -K 2 CO 3 (pH10) solution, slowly add 25g of carbon disulfide dropwise, stir gently at 20°C for 15h, then rinse with deionized water, ethanol, diethyl ether, the obtained membrane product is at P 2 o 5 Dry under vacuum at room temperature.

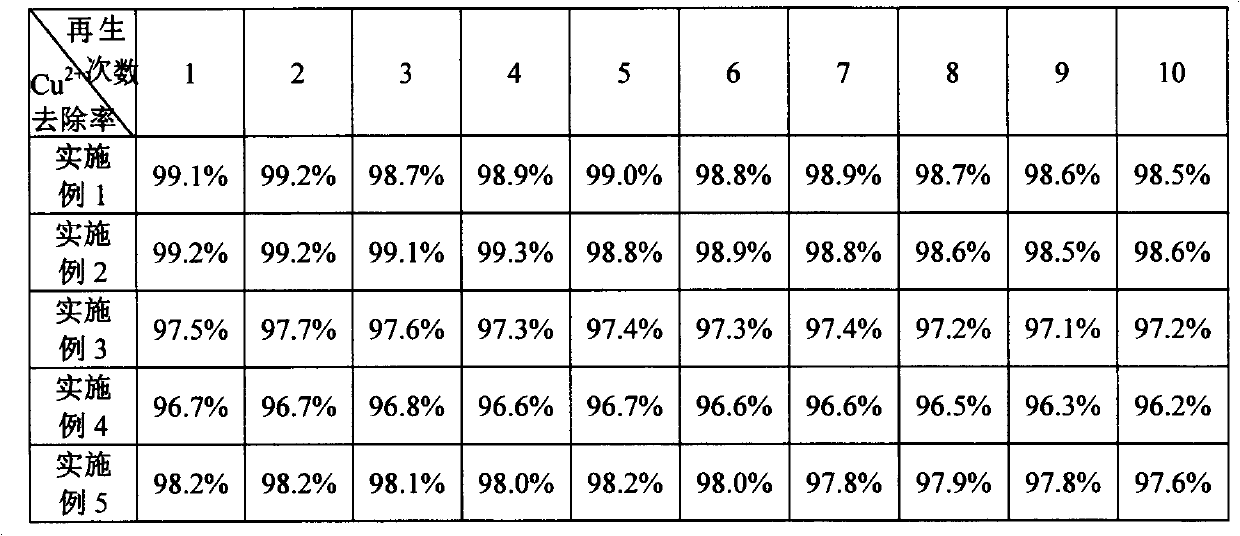

[0018] Take 1 g of the obtained membrane and soak it directly in a water sample containing heav...

Embodiment 2

[0019] Embodiment 2: DTC chitosan / polypropylene composite film

[0020] 5 g of chitosan with a deacetylation degree of 95% was dissolved in 2 wt % acetic acid aqueous solution to obtain a 2 wt % chitosan acetic acid solution. Filter to remove insoluble impurities, let it stand to remove air bubbles, mix with 2wt% glutaraldehyde aqueous solution in a mass ratio of 2:1, and evenly coat it on the polypropylene base film, with an average coating thickness of 0.2 μm, and cure at 70°C Membrane 3h, make chitosan cross-linking reaction. Then the membrane was immersed in 0.2mol / L KHCO 3 -K 2 CO 3 (pH10) solution, slowly add 20g of carbon disulfide dropwise, stir gently at 40°C for 5h, then rinse with deionized water, ethanol, diethyl ether, the obtained membrane product is at P 2 o 5 Dry under vacuum at room temperature.

[0021] Take 1 g of the obtained membrane and soak it directly in a water sample containing heavy metal ions with a concentration of 1 mmol / L for adsorption. Ad...

Embodiment 3

[0022] Embodiment 3: DTC chitosan / polysulfone composite membrane

[0023] 5 g of chitosan with a deacetylation degree of 98% was dissolved in 5 wt % acetic acid aqueous solution to obtain a 10 wt % chitosan acetic acid solution. Filter to remove insoluble impurities, stand to remove air bubbles, mix with 0.15wt% glutaraldehyde solution at a mass ratio of 1:1, and evenly coat the outer surface of the polysulfone membrane with an average coating thickness of 0.25 μm, at 90°C The film was cured for 4 h, and finally rinsed with deionized water to remove residual glutaraldehyde. Then the membrane was immersed in 0.2mol / L KHCO 3 -K 2 CO 3 (pH10) solution, slowly add 25g of carbon disulfide dropwise, stir gently at 30°C for 10h, then wash with deionized water, ethanol, diethyl ether, the resulting membrane product is at P 2 o 5 Dry under vacuum at room temperature.

[0024] Take 1 g of the obtained membrane and soak it directly in a water sample containing heavy metal ions with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com