Self-assembled modified polylactic acid material of lysozyme and mushroom polysaccharide sulfate and preparation method thereof

A technology of polylactic acid materials and lentinan, which is applied in the field of biomedical materials and biomacromolecular self-assembly, can solve the problems of lack of bioactive groups on the surface of polylactic acid materials, reduced biocompatibility, and no antibacterial properties. Achieve the effect of maintaining natural conformation and biological activity, improving biocompatibility, and good antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

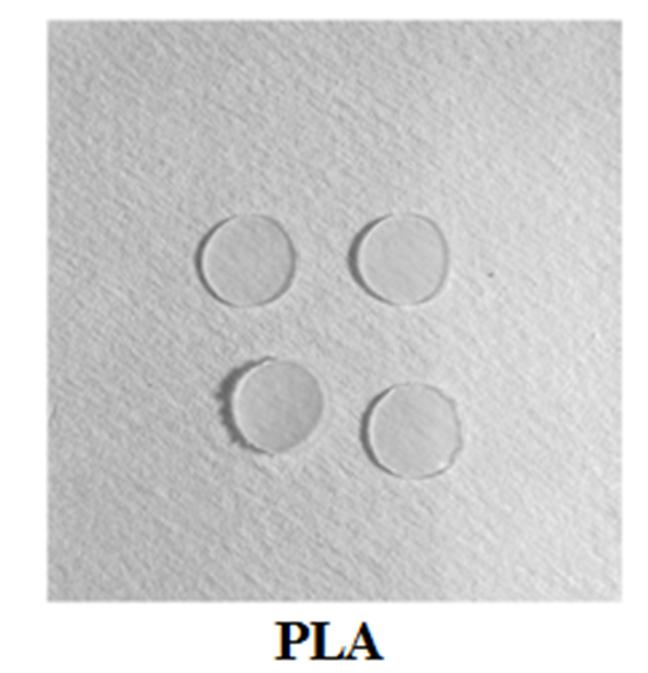

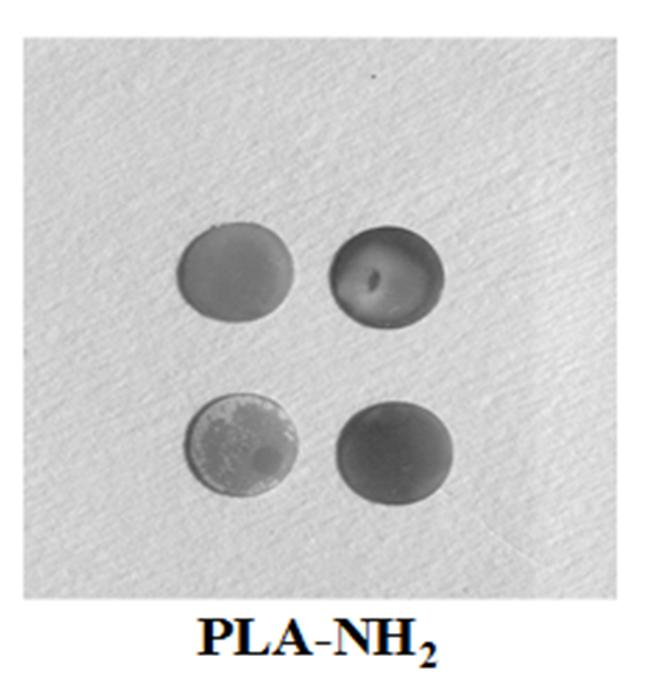

Image

Examples

Embodiment 1

[0038] A kind of preparation method of polylactic acid material modified by lysozyme and lentinan sulfate self-assembly, it comprises the following specific steps:

[0039] 1) Preparation of lentinan sulfate derivatives:

[0040] Add 0.6g lentinan into a reaction flask containing 50mL dimethyl sulfoxide, stir at 20°C for 12 hours, then slowly add 9mL pyridine dropwise at a rate of 2mL / min, continue stirring for 30 minutes, and then the reaction Place the bottle in an ice bath, slowly add 3.7 mL of chlorosulfonic acid (the molar ratio of chlorosulfonic acid to pyridine is 1:2) drop by drop with a constant pressure funnel at a rate of 0.5 mL / min, and then raise the temperature to 80 Continue to stir the reaction for 100 minutes at ℃, cool to room temperature after the reaction stops, adjust the pH to 7.0 with a NaOH solution with a concentration of 5wt%, and obtain a reaction solution; then inject the obtained reaction solution into a regenerated cellulose dialysis bag (36mm, Mw...

Embodiment 2

[0059] A kind of preparation method of polylactic acid material modified by lysozyme and lentinan sulfate self-assembly, it comprises the following specific steps:

[0060] 1) Preparation of lentinan sulfate derivatives:

[0061] Add 1.2g lentinan into a reaction flask containing 100mL dimethyl sulfoxide, stir at 30°C for 18 hours, then slowly add 18mL pyridine dropwise at a rate of 4mL / min, continue stirring for 40 minutes, and then the reaction Place the bottle in an ice bath, slowly add 7.4mL of chlorosulfonic acid (the molar ratio of chlorosulfonic acid to pyridine is 1:2) dropwise with a constant pressure funnel at a rate of 1mL / min under stirring, and then heat up to 80°C Continue to stir the reaction for 120 minutes, cool to room temperature after the reaction stops, adjust the pH to 7.0 with 5wt% NaOH to obtain a reaction solution; then inject the obtained reaction solution into a regenerated cellulose dialysis bag (36mm, Mw: 8000-14000) , dialyzed in NaOH solution wi...

Embodiment 3

[0073] A kind of preparation method of polylactic acid material modified by lysozyme and lentinan sulfate self-assembly, it comprises the following specific steps:

[0074] 1) Preparation of lentinan sulfate derivatives:

[0075] Add 0.6g lentinan into a reaction flask containing 50mL dimethyl sulfoxide, stir at 25°C for 16 hours, then slowly add 18mL pyridine dropwise at a rate of 3mL / min, continue stirring for 35 minutes, and then the reaction Place the bottle in an ice bath, slowly add 3.7mL of chlorosulfonic acid (the molar ratio of chlorosulfonic acid to pyridine is 1:4) dropwise with a constant pressure funnel at a rate of 1mL / min under stirring, and then heat up to 80°C Continue to stir the reaction for 120 minutes, cool to room temperature after the reaction stops, adjust the pH to 7.0 with 10wt% NaOH to obtain a reaction solution; then inject the obtained reaction solution into a regenerated cellulose dialysis bag (36mm, Mw: 8000-14000) , dialyzed in a NaOH solution ...

PUM

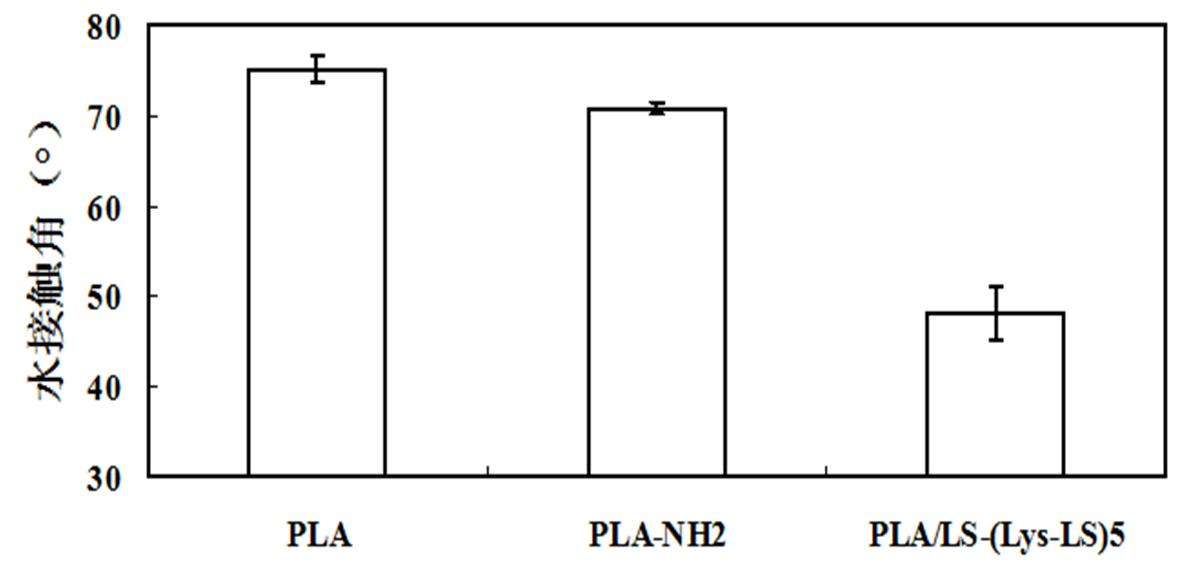

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com