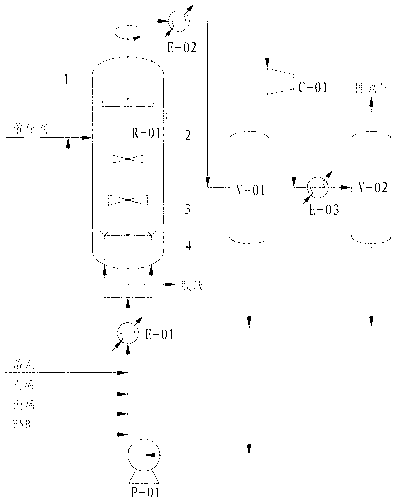

Polymerization reactor for producing ethylene propylene diene monomer by using solution method and process flow control method

A technology of EPDM rubber and polymerization reactor, which is applied in the direction of comprehensive factory control and electrical program control, which can solve the problems of monomer imbalance, unstable liquid level control, and liquid "flooding" to prevent unqualified The production of defective or defective products, the improvement of polymerization process control, the effect of reduction in yield and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

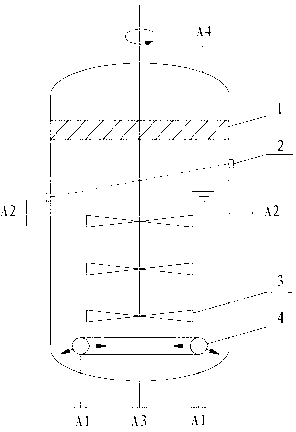

[0088] In a 65 cubic meter reactor, hexane is used as a solvent, and the liquid level is 60% of the height of the reactor. The designed reactor can well ensure that the monomer, solvent and catalyst components are evenly dispersed.

[0089] The stirring system of the polymerization solution ensures the uniform mixing of the components of the solution in the reactor and ensures that the residence time of each component is constant.

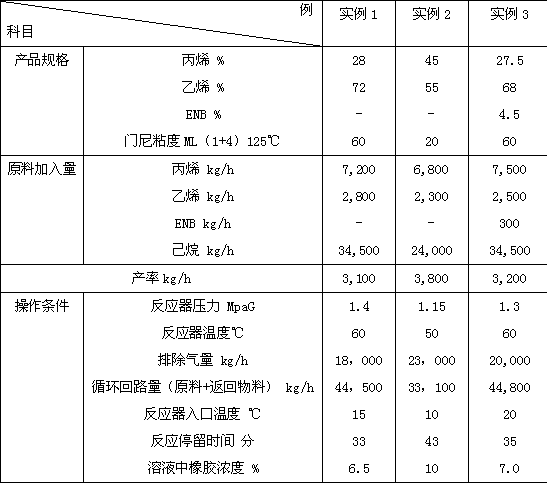

[0090] The design of the entire system of the reaction part (container, agitator, top light monomer evaporation and exhaust circulation loop, and related instruments connected to DCS) can produce more than 20 grades of EPDM rubber. Using this reactor, typical Examples 1-3 are shown in Table 1 below.

[0091] Table 1. Examples 1-3 (reactor volume 65m 3 , diameter 3.5m, height 7m, 3-layer stirring paddle) process conditions and results

[0092]

[0093] The invention's original reactor with a stirring system and original polymerization process c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com