Continuous negative pressure dryer and continuous drying method

A drying machine and negative pressure technology, which is applied in the direction of local stirring dryers, static material dryers, dryers, etc., can solve the problem that the drying temperature and drying time cannot be controlled at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

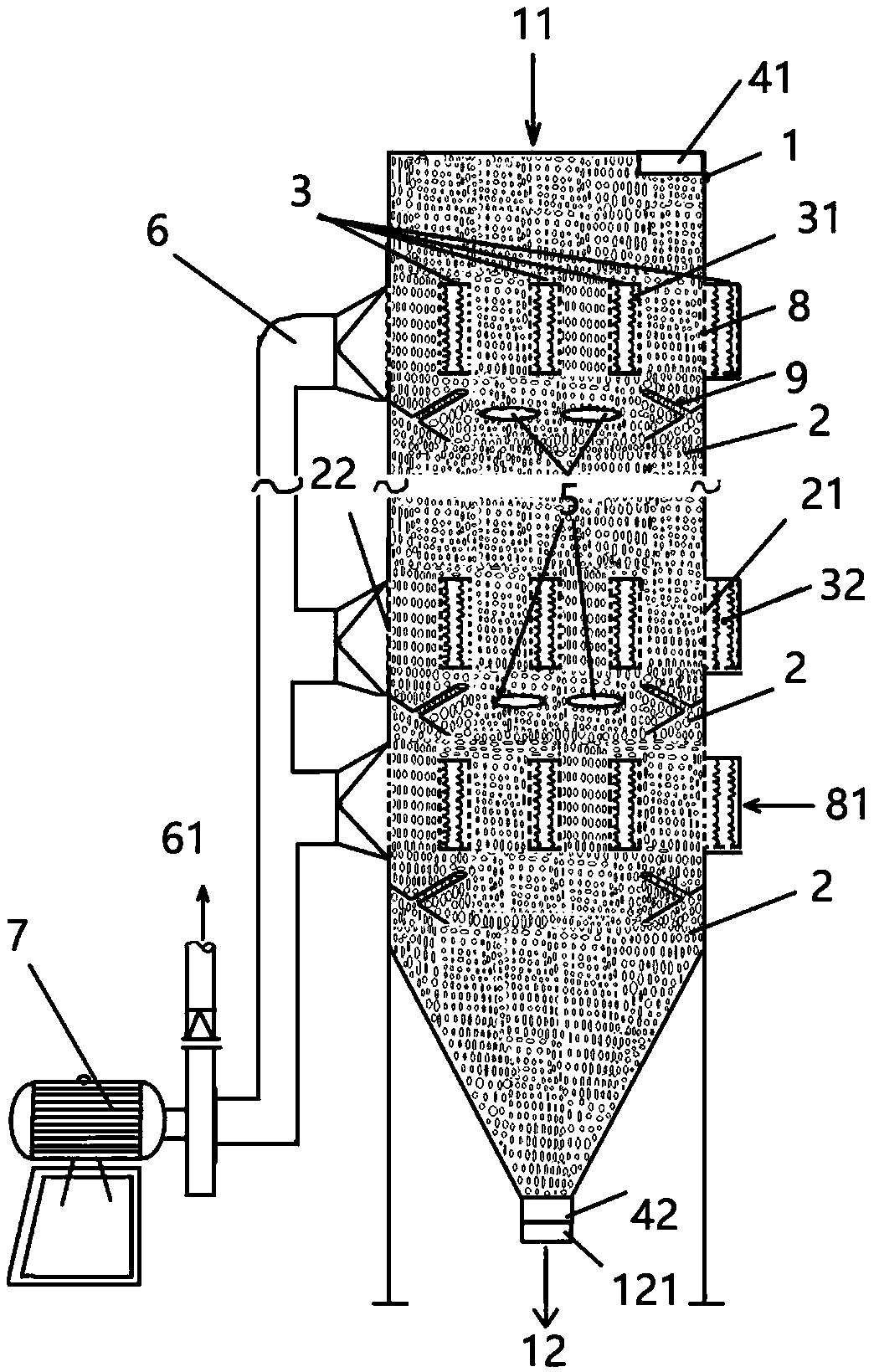

[0051] This embodiment provides a negative pressure continuous dryer, its structure is as follows figure 1 As shown, it includes a vertically arranged bin body 1 , the top of the bin body 1 is a feeding port 11 , and the bottom is a feeding port 12 . The grain is put into the bin body 1 from the feed port 11, heated and dried in the bin body 1 to remove moisture, and then discharged from the discharge port 12 to complete the drying process. In this embodiment, the material passes through the interior of the bin body 1 from top to bottom under the action of its own weight, and several drying layers 2 are distributed along the moving direction of the material. Each drying layer 2 is equipped with a heating unit 3 for heating and drying the material. . An air outlet 22 is opened on the side wall of the bin body 1, and the negative pressure device connected to the air outlet 22 of the bin body 1 discharges the air in the bin body 1, forming a negative pressure in the bin body 1, ...

Embodiment 2

[0070] This embodiment provides a negative pressure continuous dryer, the difference between its structure and the negative pressure continuous dryer in Example 1 is that there is no temperature sensor in each drying layer, instead there is a temperature sensor in each drying layer A moisture detection device is provided to detect the moisture content of the material in the drying layer, and the control device controls the working temperature of the heating unit in the adjacent next drying layer according to the detection result of the material in the upper drying layer.

Embodiment 3

[0072] This embodiment provides a kind of continuous drying method, utilizes the negative pressure continuous dryer that provides in the embodiment 1 to carry out the following operation steps to the grain:

[0073] S1: The grain is sent into the bin body from the feed port;

[0074] S2: heat and dry the grain in the bin body, comprising the following steps:

[0075] S21: adopt the first moisture detector that is positioned at feed inlet place to detect grain, obtain original moisture content M 0 , and feed back the result to the control device;

[0076] S22: The control device according to the above original moisture content M 0 The detection result controls the heating temperature of the heating unit in the first drying layer;

[0077] Specifically, different drying stages corresponding to the moisture content range of the grain and the temperature of the grain itself are pre-registered in the control system, and the corresponding heating temperature needs to be set for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com