vaporizer

A gasifier and gasification technology, applied in the field of gasifiers, can solve problems such as fluctuations in the supply concentration of gasification gas, and achieve the effects of preventing uneven temperature and uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Hereinafter, an Example and a comparative example are given, and this invention is demonstrated more concretely. However, the present invention is not limited by the following examples.

Embodiment

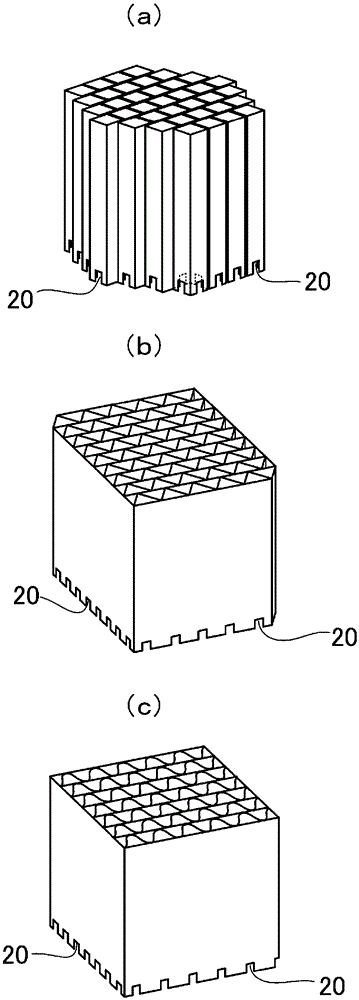

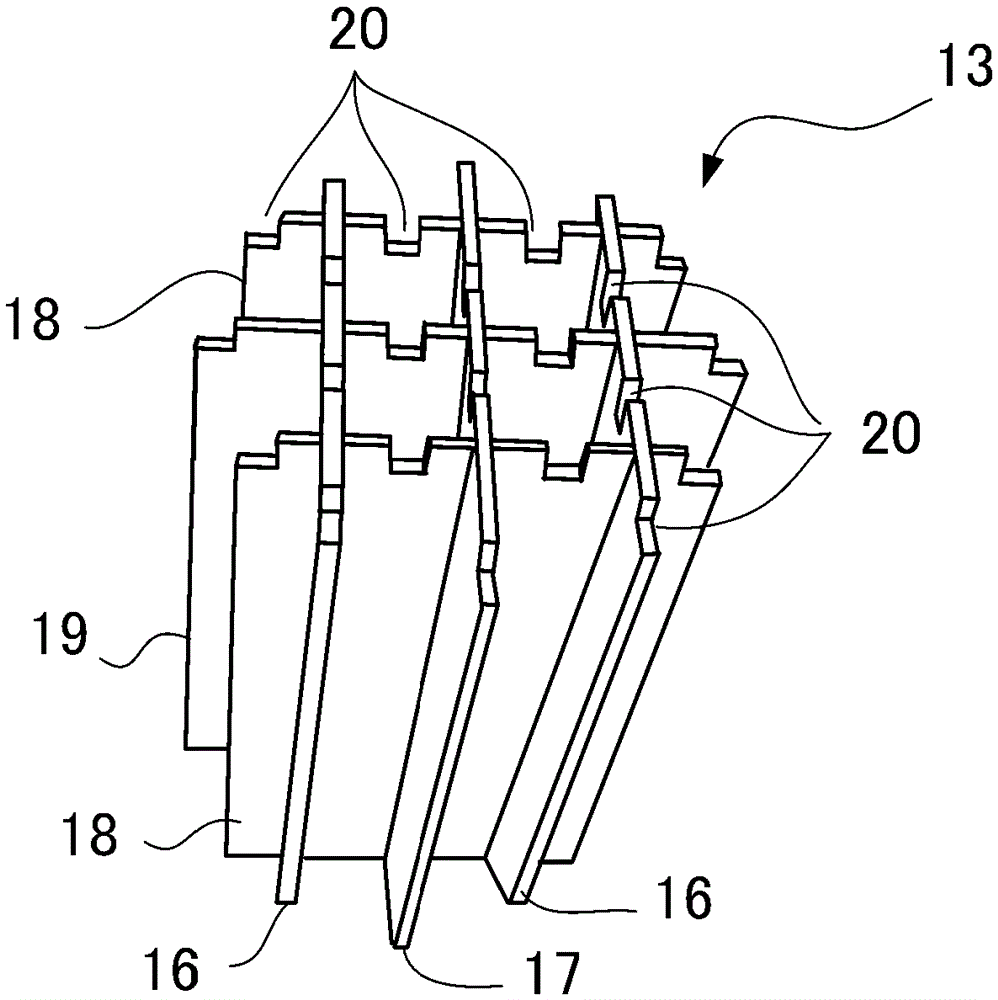

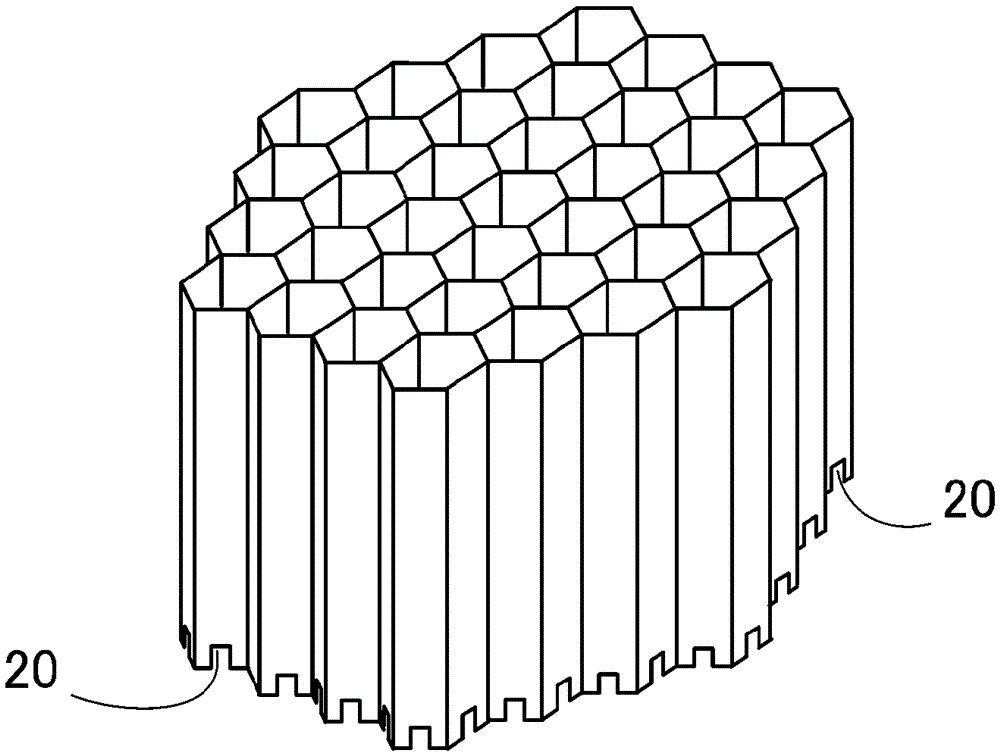

[0051] In the example, using the figure 1 The same system as the liquid material gasification supply system shown, housed in the gasifier Figure 2-4 A grid-like partition wall structure of the shape shown. The grid-like partition wall structure is formed of a stainless steel plate with a thickness of 0.5 mm, the grid interval (the length of one side of a grid division) is 3.6 mm, the height is 2.5 cm, and the height of the notched recesses constituting the liquid flow part is 1 mm. As the liquid material, TMGa (trimethylgallium) was used. The pressure of the pressure-feeding gas (nitrogen) was set at an absolute pressure of 200 kPa. The heating device was controlled so that the temperature in the vaporizer became 75°C. The pressure on the downstream side of the pressure-adjustable flow control device was set to 1.8 Torr, and the flow rate was controlled to 56 sccm by the pressure-adjustable flow control device. When the TGMa of the liquid in the vaporizer decreases and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com