Cerium oxide/ aluminium oxide micro-nanostructure ceramic pigment and preparation method thereof

A technology of micro-nano structure and ceramic pigment is applied in the field of preparation of micro-nano structure materials, which can solve the problems of difficult morphology control and large product particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

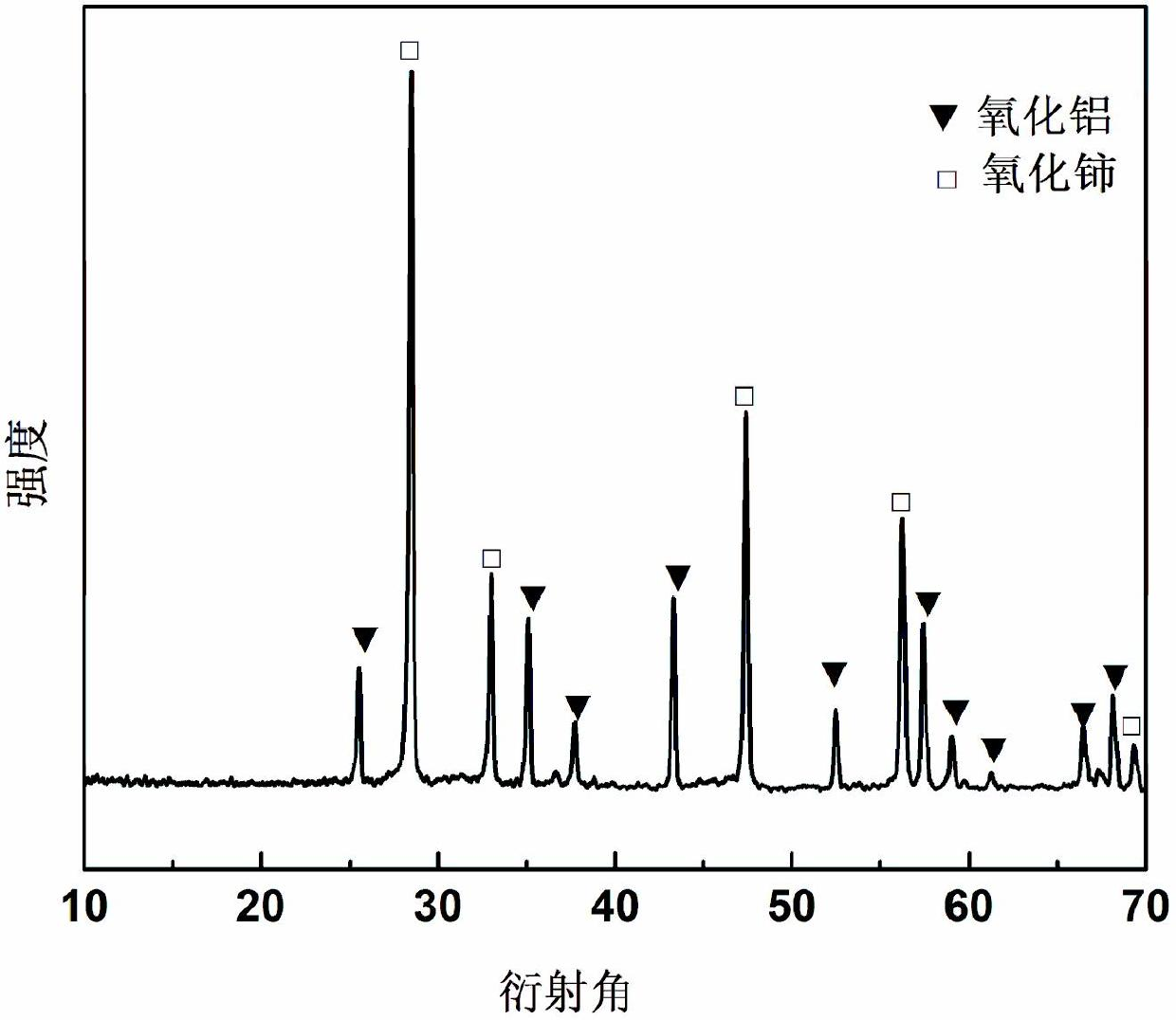

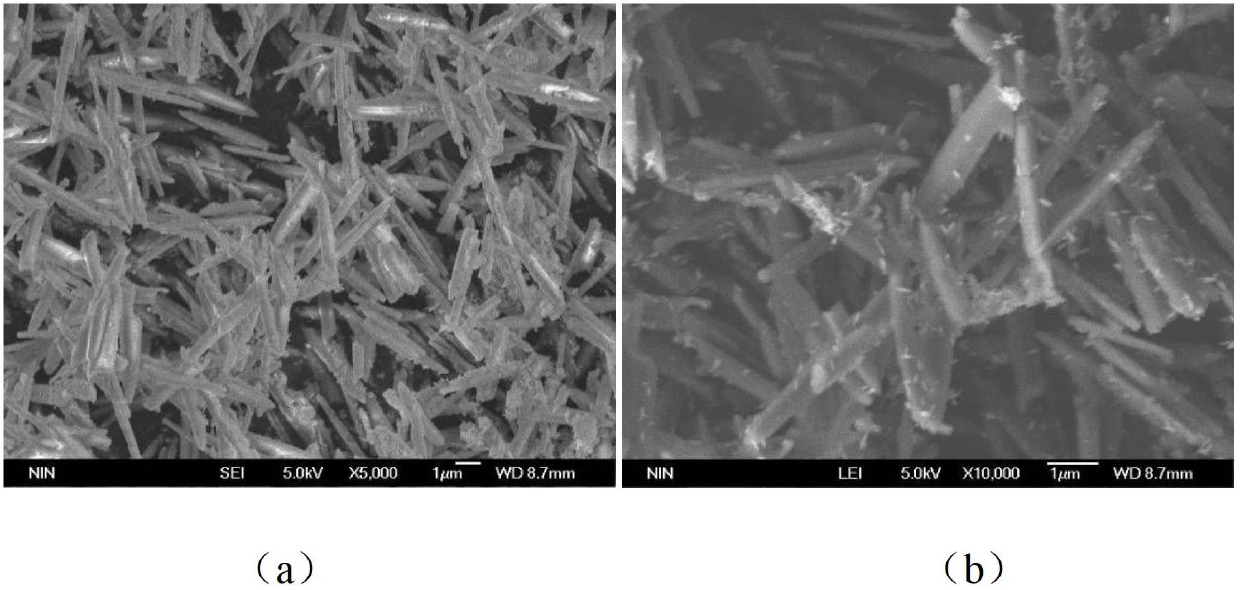

[0030] Prepare 35 mL of 0.03 mol / L cerium chloride solution. After fully stirring and mixing, add 7.5 g of aluminum nitrate nonahydrate to dissolve completely. The molar ratio of cerium salt and aluminum salt is 1:20. Dissolve 8 g of polyethylene glycol 20000 A transparent solution was formed in the mixed solution, and 20 g of urea was added to the solution and stirred until dissolved. The mixed solution was transferred to a Teflon-lined reactor and sealed. The reaction kettle was placed in an oven at a constant temperature of 120°C for 22 hours, and the reaction kettle was taken out and cooled to room temperature naturally. The white product in the hydrothermal kettle was collected and washed several times with deionized water and absolute ethanol, and then the product was dried in a vacuum drying oven at 60° C. for 24 hours to obtain a white powder. The above white powder was placed in a muffle furnace, calcined at 1200° C. and kept for 2 hours, and then cooled to room temp...

Embodiment 2

[0032] Prepare 35 mL of 0.09 mol / L cerium chloride solution. After fully stirring and mixing, add 7.5 g of aluminum nitrate nonahydrate to dissolve completely. The molar ratio of cerium salt and aluminum salt is 3:20. Dissolve 6 g of polyethylene glycol 20000 A transparent solution was formed in the mixed solution, and 19.2 g of urea was added to the solution and stirred until dissolved. The mixed solution was transferred to a Teflon-lined reactor and sealed. The reaction kettle was placed in an oven at a constant temperature of 120°C for 26 hours, and the reaction kettle was taken out and cooled to room temperature naturally. The white product in the hydrothermal kettle was collected and washed several times with deionized water and absolute ethanol, and then the product was dried in a vacuum drying oven at 60° C. for 24 hours to obtain a white powder. The above white powder was placed in a muffle furnace, calcined at 1200° C. and kept for 2 hours, and then cooled to room te...

Embodiment 3

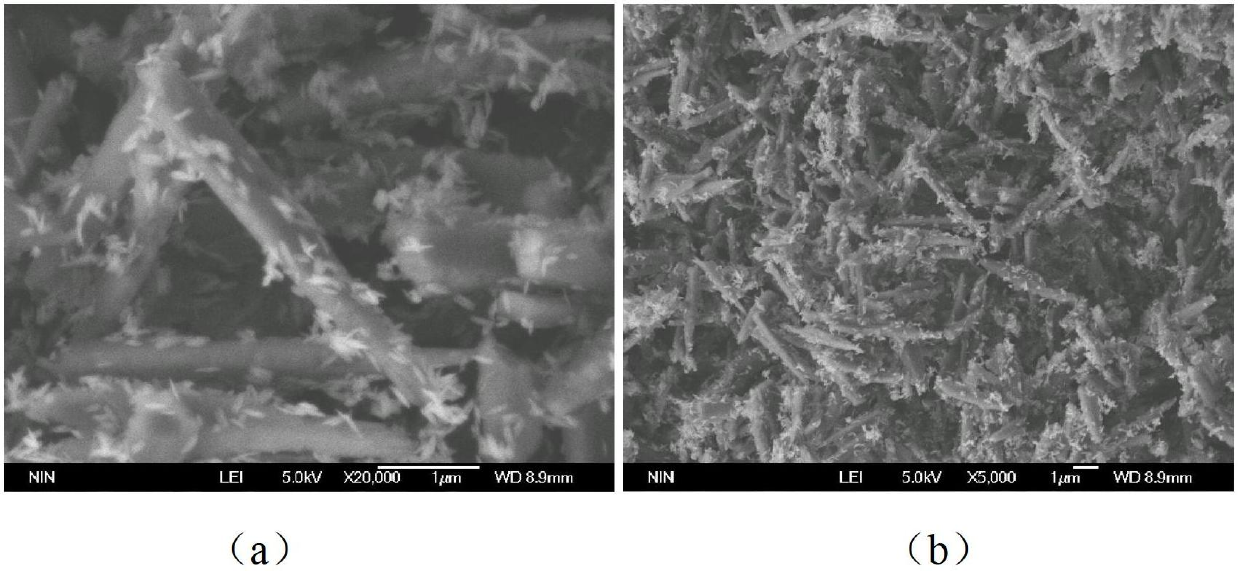

[0034]Prepare 35 mL of 0.06 mol / L cerium chloride solution. After fully stirring and mixing, add 7.5 g of aluminum nitrate nonahydrate to dissolve completely. The molar ratio of cerium salt and aluminum salt is 1:10. Dissolve 12 g of polyethylene glycol 20000 A transparent solution was formed in the mixed solution, and 20.4 g of urea was added to the solution and stirred until dissolved. The mixed solution was transferred to a Teflon-lined reactor and sealed. The reaction kettle was placed in an oven at a constant temperature of 120°C for 24 hours, and the reaction kettle was taken out and cooled to room temperature naturally. The white product in the hydrothermal kettle was collected and washed several times with deionized water and absolute ethanol, and then the product was dried in a vacuum drying oven at 60° C. for 24 hours to obtain a white powder. The above white powder was placed in a muffle furnace, calcined at 1200° C. and kept for 2 hours, and then cooled to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com