In-pipe cutting device for heat transfer surface pipe of reactor steam generator

A technology of steam generator and heat transfer surface, applied in pipe shearing device, shearing device, shearing machine, etc., can solve the problems of large dose of personnel exposure, long operation time, low degree of automation, etc., and reduce labor intensity and radiation exposure dose, small size, and the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

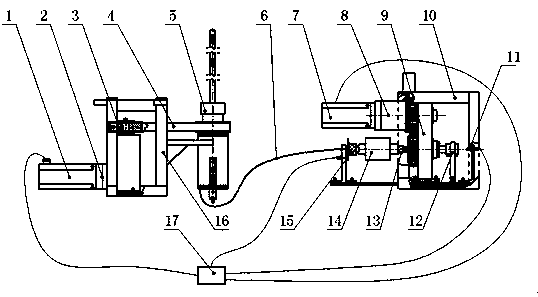

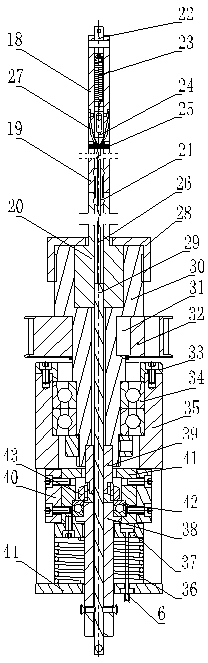

[0020] Such as figure 1 As shown, the cutting device of the present invention includes a rotating part, a knife feeding part and an electric control system 17, and the rotating part and the knife feeding part are connected to each other by a brake wire steel wire 6, and are respectively connected to the electric control system 17 through wires.

[0021] Rotating parts: It consists of a rotating part servo motor 1, a rotating part reducer 2, an active synchronous pulley 3, a synchronous belt 4, a cutting assembly 5 and a rotating part frame 16.

[0022] The rotating part servo motor 1 and the rotating part reducer 2 are fixed on the rotating part frame 16 with screws after being connected with the shaft and the connection key; the cutting assembly 5 is fixed on the rotating part frame 16 through screws; the rotating part reducer 2 and the active After the synchronous belt pulley 3 is connected with the connecting key with a shaft, it is connected with the cutting assembly 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com