Radioactive anion resin microsphere and method for preparing same

An anion resin, anion technology, applied in the directions of radioactive carrier, radioactive physical shape, drug combination, etc., can solve the problems of high purity requirements of raw materials, complex preparation process, dependence on reactors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1: 32 P anion resin microspheres

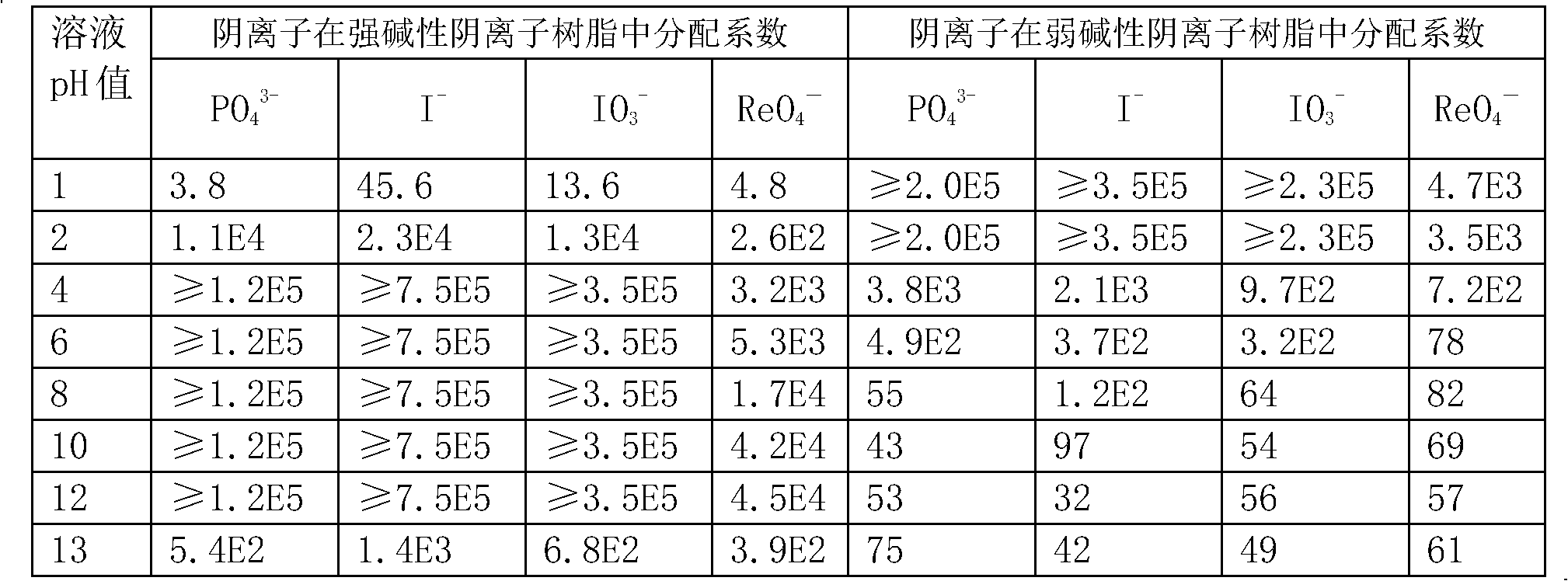

[0063] (1) the styrene-divinylbenzene anion-exchange resin (201 × 7 resin) that 2g crosslinking degree is 4%, and diameter is 10 μm~100 μm is transformed into OH type strongly basic anion resin;

[0064] (2) under room temperature conditions, the strong basic anion resin obtained in step (1) contains 8GBq in 20mL, pH value is 10 32 Na of P 3 PO 4 React in the solution for 1 hour, and exchange the radionuclide anion to the inside of the anion resin;

[0065] Get the reaction solution and use BH1216 type low background α, β measuring instrument (produced by Beijing Nuclear Instrument Factory) to measure remaining in the solution 32 P activity, calculated 32 P utilization rate, and then wash the resin with water until the pH value of the cleaning solution is less than 8;

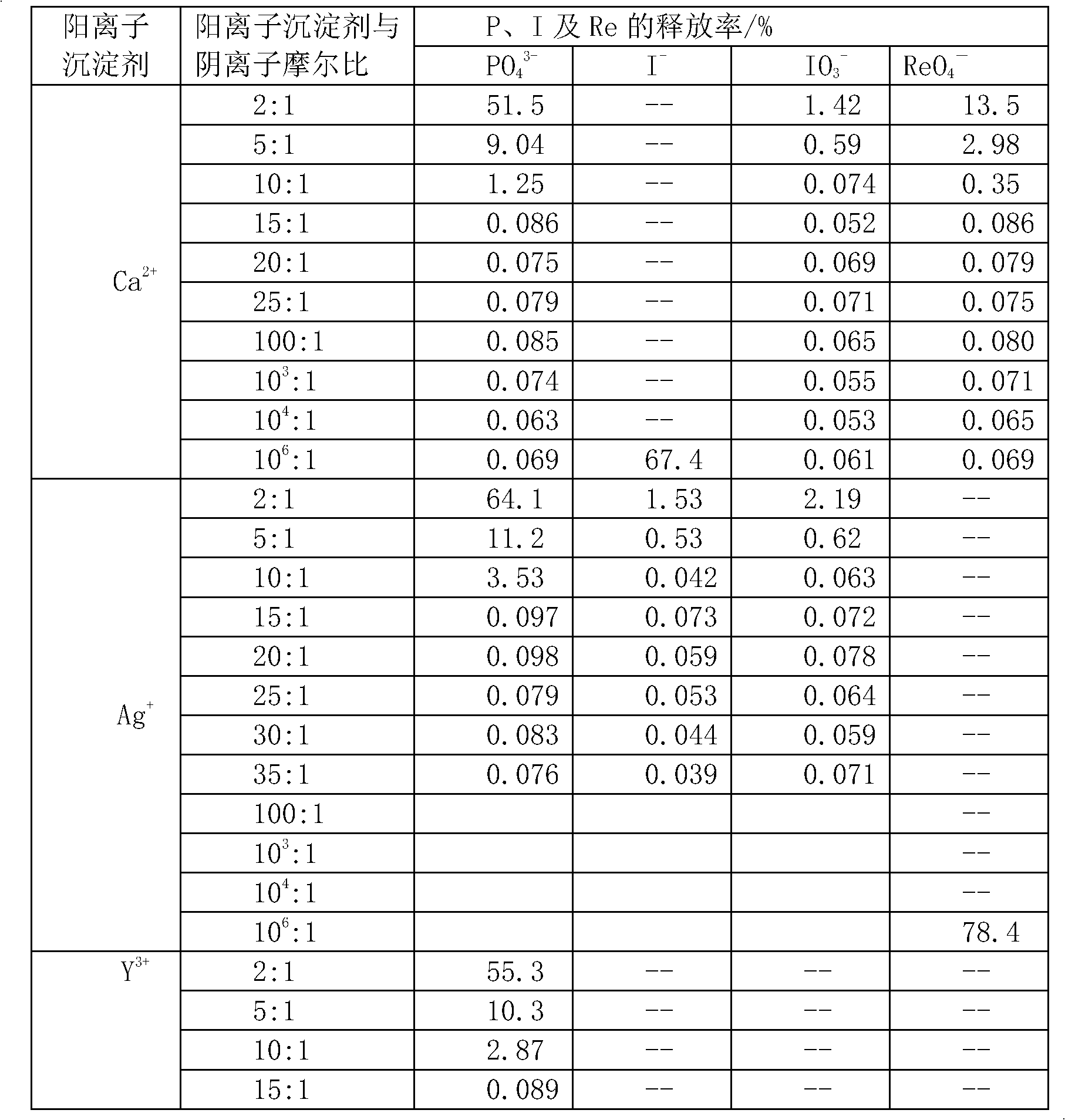

[0066] (3) Exchange 1g of them with 32 The resin of P was added to 20 mL of YCl containing 200 μg Y at pH 5 3 solution, react at room temperature for 4h...

Embodiment 2

[0072] Embodiment 2: I-131 anionic resin microspheres

[0073] Put 2g of OH-type strongly basic styrene-divinylbenzene anion exchange resin (201×7 resin) with a cross-linking degree of 4% and a diameter of 10 μm to 100 μm at room temperature in 20 mL of a pH value of 10 containing 5.2 GBq Soak in the NaI solution of I-131 for 1 hour, and exchange the radionuclide anion to the inside of the anion resin;

[0074] Get above-mentioned reaction gained reaction solution, measure remaining I-131 activity in the solution with F-613 type radioactivity counter (Beijing Nuclear Instrument Factory), calculate the utilization rate of I-131, then clean resin with water to the pH value of cleaning solution less than 8;

[0075] Add 1 g of I-131-exchanged resin to 20 mL of AgNO containing 1 mg of Ag at pH 3 3 solution, react at room temperature for 3 hours, wash with distilled water until the pH of the washing liquid is 6, then soak in 1mol / L NaOH solution for 4 hours, and filter to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com