Continuous preparation equipment and process for fiber-reinforced metal glass composite filament

A technology of metallic glass and composite materials, applied in the field of amorphous alloys, which can solve the problems of long contact time between fibers and alloy liquid, and reduced effect of reinforcements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

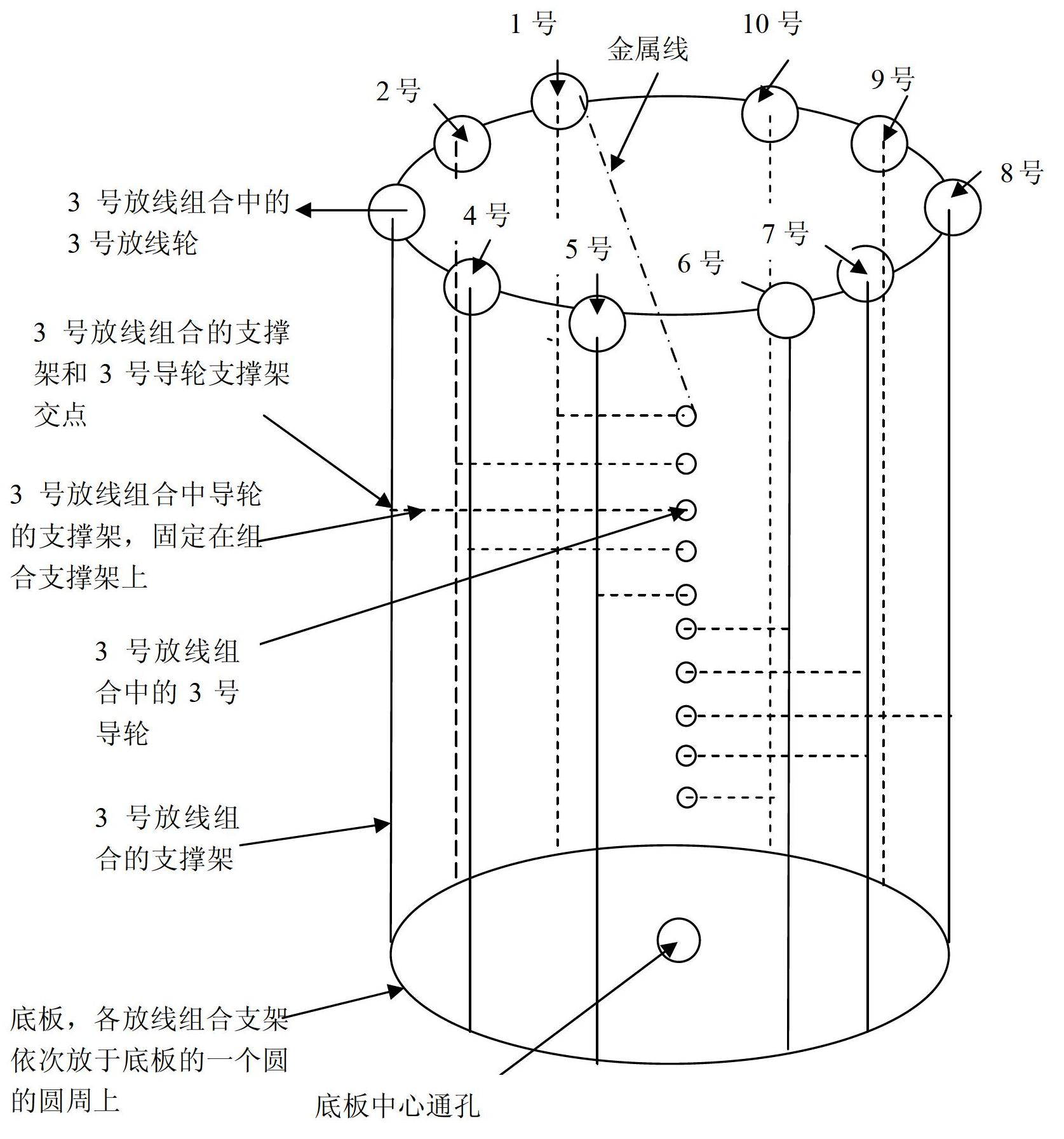

Method used

Image

Examples

Embodiment 1

[0034] Zr, Ti, Cu, Ni and Be with a purity greater than 99.99% are arc-melted in an argon atmosphere adsorbed by titanium according to the nominal composition ratio, mixed evenly, and cooled to obtain an ingot. The tungsten wire with a diameter of 80 μm was electrochemically polished in 5% NaOH solution to remove the surface oxide film, and then washed in water. The treated tungsten wire is wound on the guide wheel on the upper part of the traction mechanism, and the lead-out part together with the pulverized master alloy is put into the crucible with a small hole at the bottom. One end of the tungsten wire passes through the small hole of the crucible from the inside to the outside. Remelt the Vit1 master alloy at 820oC in the heating furnace and keep it warm. Then, the metal wire impregnated in the melt is pulled down by the motor at a rate of V=30mm / s through the traction mechanism, so that the surface is uniformly impregnated with a layer of alloy liquid. After passing thro...

Embodiment 2

[0036] The technical solution is as in Example 1. In the continuous seepage process, 24 tungsten wires are selected, the diameter of the tungsten wire is 80um, the alloy remelting temperature is adjusted to 750oC, the casting speed of the monofilament coating is adjusted to be V=40mm / s, and the subsequent continuous The pulling speed during the infiltration process is V=20mm / s, and high-quality continuously prepared tungsten wire-reinforced zirconium-based metallic glass composite wire can be obtained. Cross-sectional SEM photos, X-ray diffraction patterns (XRD) and thermal analysis curves (DSC) are as follows Figure 6 , Figure 7 red curve, Figure 5 Shown by the black curve. From Figure 6 It can be seen from the figure that the edge of the tungsten wire is very clear and smooth, no obvious dissolution and exfoliation occurs, and the interface of the composite material is very smooth. From Figure 7 It can be seen that the diffraction peak of the uncomposited sample is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic limit | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com