Slurry acetylene recycling device

A recovery device and acetylene technology, which is applied in the field of wet acetylene generators, can solve problems such as liquid-sealed tank blockage, and achieve the effects of simple operation, significant economic benefits, and excellent safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with embodiment.

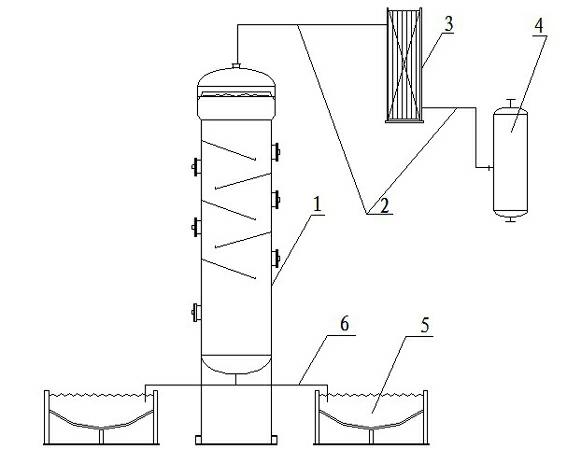

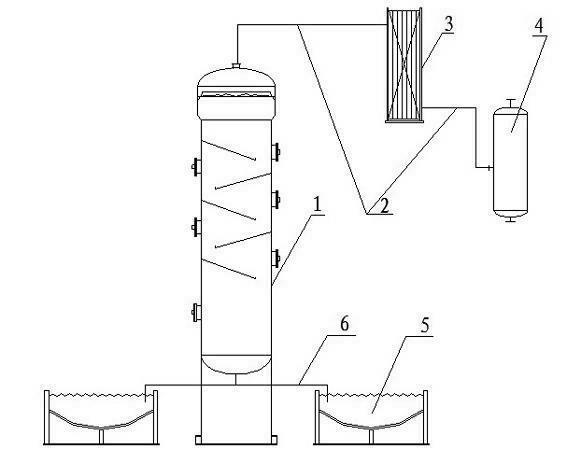

[0010] see figure 1 , the slurry acetylene recovery device is composed of a stripper 1, an acetylene cooler 3, a steam-water separator 4, and a concentration tank 5. The upper part of the stripper 1 is connected with the acetylene flash steam inlet of the acetylene cooler 3 through a pipeline 2, and the acetylene The lower part of the cooler 3 is connected with the steam-water separator 4 through the pipeline 2, and the outlet of the slurry feeding pipe 6 at the bottom of the stripping tower 1 is directly connected with the concentration tank 5 and submerged under the liquid surface of the concentration tank 5; It should be ensured that the stripper 1 acts as a liquid seal. In the figure, there are two concentrating pools 5.

[0011] The operating process of the present invention is briefly described as follows:

[0012] The slurry produced by the wet acetylene generator is forced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com