Packing type graded cementing device

A graded cement injection and isolation technology, which is used in sealing/packing, wellbore/well components, earth-moving drilling, etc. The effect of reducing the difficulty of operation and improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

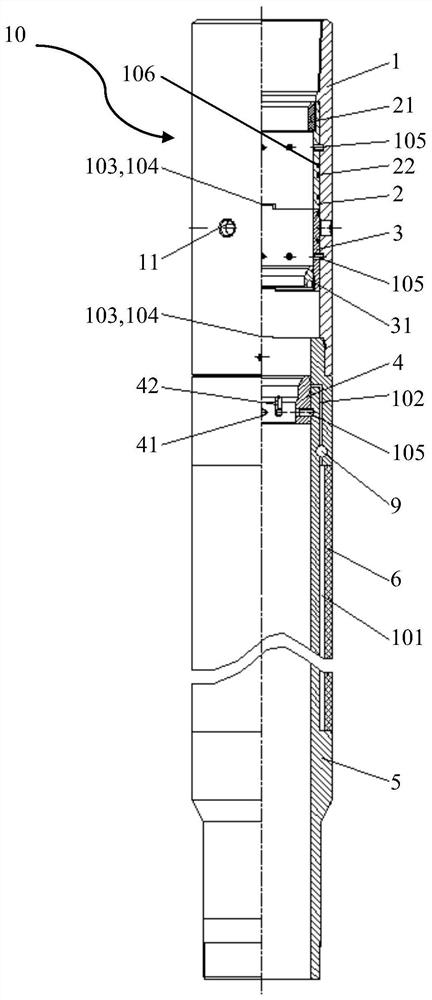

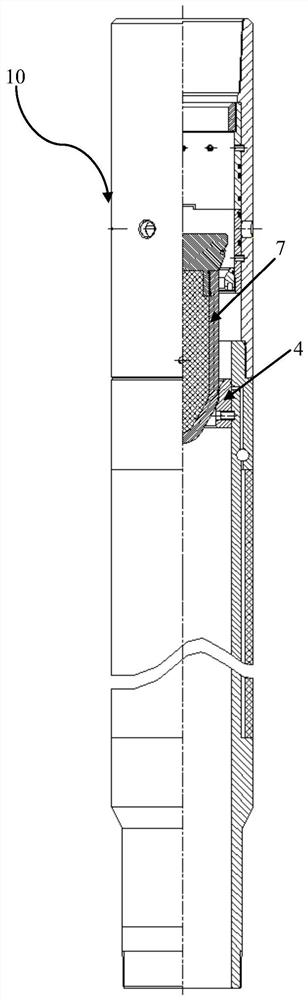

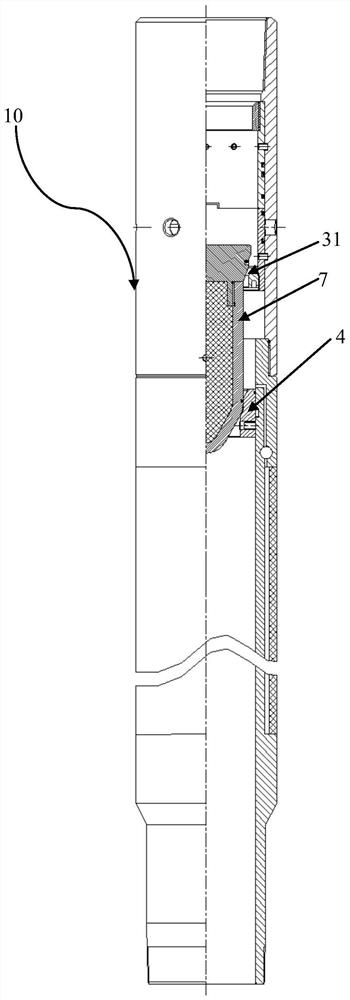

[0043] figure 1 Schematically shows the initial state of the isolated staged cementing device 10 of the embodiment of the present invention. figure 2 It schematically shows the state in which the plug opening of the sealed staged cementing device 10 of the embodiment of the present invention reaches the position of the swelling seal base. image 3 It schematically shows the open state of the liquid injection channel of the isolated staged cementing device 10 of the embodiment of the present invention. Figure 4Schematically shows the swelling state of the pack-off staged cementing device 10 of the embodiment of the present invention. Figure 5 It schematically shows the sealing state of the sealing-type staged cementing device 10 of the embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com