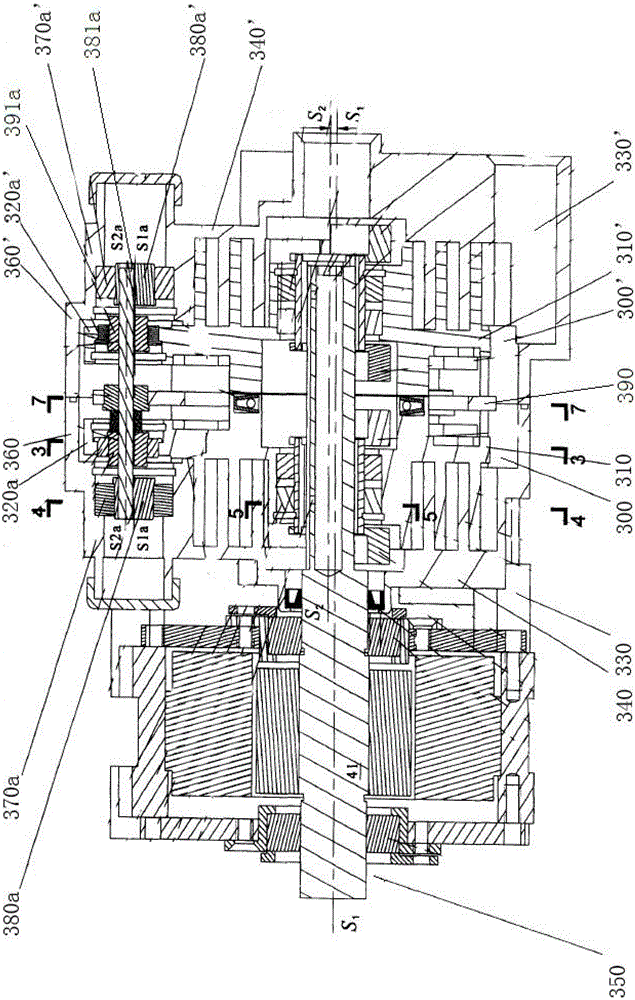

Scroll vacuum pump with magnetic fluid translational sliding thrust bearing and sealing structure

A technology of sliding thrust bearing and sealing structure, which is applied to parts of pumping devices for elastic fluid, pump parts of rotary piston type/oscillating piston type, rotary piston type pumps, etc., and can solve the problem that vacuum pumps cannot meet the sealing requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

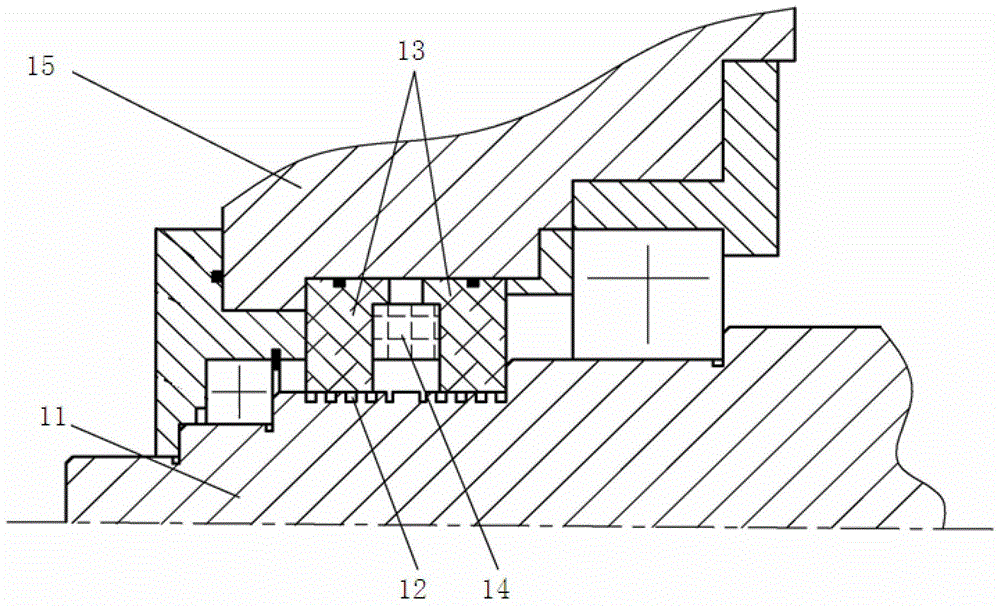

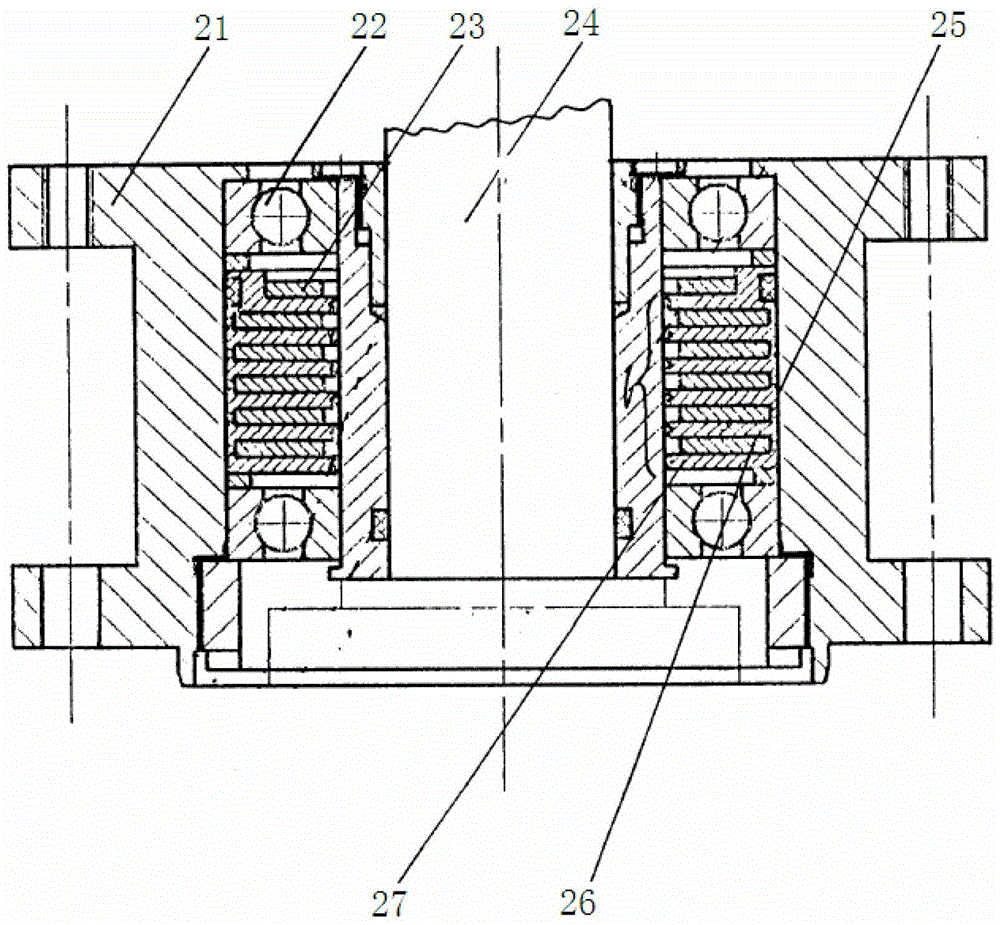

[0042] In further embodiments of the present invention, please refer to Figure 4 to Figure 7 Shown. The end surface of the magnet 72 close to the magnetic fluid is coated with a layer of anaerobic fluid coating 73. The material of the anaerobic fluid coating 73 is mainly polytetrafluoroethylene. The magnetic fluid coating 73 is used to converge The role of the magnetic fluid, thereby improving the pressure resistance and air tightness, and reducing the resistance, reducing the loss of the magnetic fluid.

[0043] In a further embodiment of the present invention, Figure 8 for Figure 5 The first scheme schematic diagram of the groove on the radial end face of the middle piston rear seat, please refer to Figure 8 Shown. The cross-sectional shape of the convex ring 92 provided between the two adjacent first annular grooves 91 on the radial end surface of the piston rear support 9 is rectangular.

[0044] In a further embodiment of the present invention, Picture 9 for Figure 5 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com