Engine pedestal trial run liquid

An engine bench and derivative technology, applied in the field of engine bench test fluid, can solve problems such as insufficient compatibility of non-metallic materials, insufficient compatibility of antifreeze, insufficient antirust ability, etc., and achieve long-term and stable performance and high temperature stability Excellent performance and long anti-corrosion period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

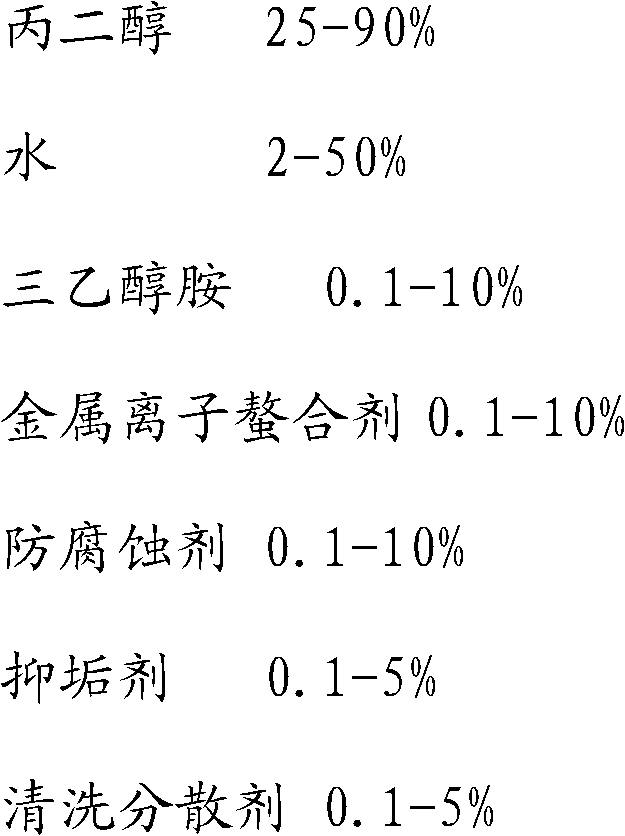

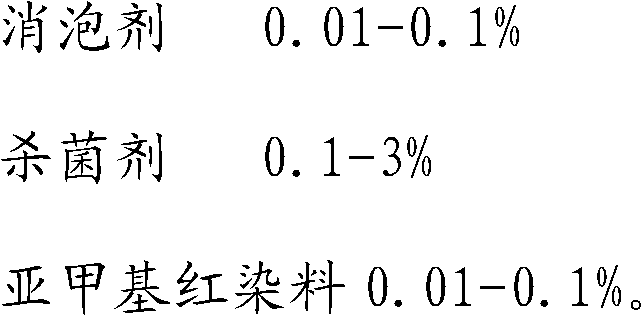

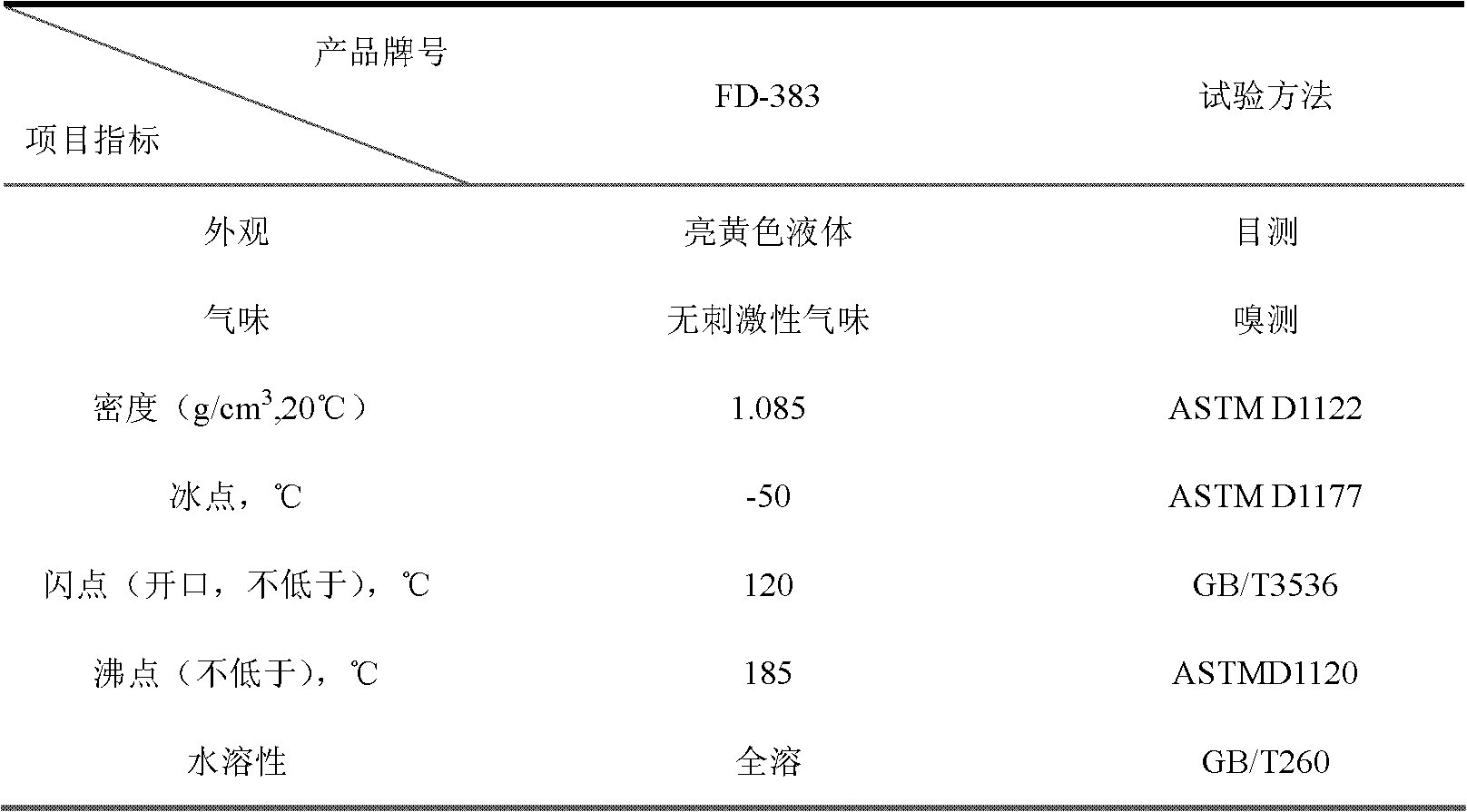

Method used

Image

Examples

Embodiment 1

[0026] Raw materials: Propylene Glycol 90%, Triethanolamine 3.0%, EDTA-2Na 0.5%, Hydroxyethylidene Diphosphonic Acid HEDP 0.6%, Sodium Benzoate 2.2%, Benzotriazole 1.2%, Polyoxygen Vinyl ether 380000 0.1%, polyethylene glycol 600 0.1%, fungicide MIT (isothiazolinone derivatives) 0.29%, methylene red dye 0.01%, and the balance is water.

[0027] It is prepared according to the following steps: according to the process requirements, weigh water, triethanolamine, ethylenediaminetetraacetic acid disodium, sodium benzoate, phenylacryltriazole, hydroxyethylidene diphosphonic acid, polyoxyethylene ether 380000, Add polyethylene glycol 600 and fungicide into a stainless steel mixing kettle with stirring device and heating function, adjust the temperature at 30-45°C and stir for 1-2.5 hours, then slowly add propylene glycol to dissolve and disperse according to the regulations, mix well and then add The methylene red dye is fully mixed and dispersed. At this time, the pH of the mixed s...

Embodiment 2

[0029] Raw materials: Propylene Glycol 49.0%, Triethanolamine 10%, Ethylenediaminetetraacetic Acid Tetrasodium EDTA-4Na 0.4%, Phosphoryl Carboxylic Acid Copolymer POCA 0.1%, Sodium Benzoate 1.8%, Adipic Acid 0.4%, Mercaptobenzotris Azole 0.8%, polyoxyethylene ether 900000.8%, polyethylene glycol 6000.01%, fungicide MBM (morpholine derivatives) 1.8%, methylene red dye 0.05%, and the balance is water.

[0030] It is prepared according to the following steps: according to the process requirements, weigh water, triethanolamine, tetrasodium ethylenediaminetetraacetic acid, sodium benzoate, adipic acid, benzotriazole, phosphoryl carboxylic acid copolymer, polyoxygen Vinyl ether 90000, polyethylene glycol 600 and fungicide MBM are added to a stainless steel mixing kettle with stirring device and heating function, and the temperature is adjusted to 30-45 ° C. After stirring for 1-2.5 hours, slowly add propylene glycol to dissolve and disperse according to the regulations , after fully...

Embodiment 3

[0032] Raw materials: propylene glycol 25%, triethanolamine 8%, ethylenediaminetetraacetic acid 10%, tricarboxylic acid 8%, aminomethyl phosphoric acid 5%, sorbitan trioleate polyoxyethylene ether 1.6%, polyethylene glycol Alcohol 4000.03%, fungicide M1T (isothiazolinone derivatives) 3%, methylene red dye 0.03%, and the balance is water.

[0033] It is prepared according to the following steps: according to the process requirements, weigh water, triethanolamine, ethylenediaminetetraacetic acid, tribasic carboxylic acid, aminomethyl phosphoric acid, sorbitan trioleate polyoxyethylene ether, polyethylene glycol Diol 400 and fungicide M1T are added to a stainless steel mixing kettle with stirring device and heating function, and the temperature is adjusted to 30-45°C. After stirring for 1-2.5 hours, slowly add propylene glycol to dissolve and disperse according to the regulations, and add sub- Methyl red dye is fully mixed and dispersed. At this time, the pH of the mixed solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com