Method for preparing adhesive for compounding aluminizing film

A technology of adhesives and aluminized films, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of low solid content of polyurethane adhesives, poor solvent release, transfer of aluminized layers, etc. problem, to achieve the effect of good wettability, less transfer amount and lower content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

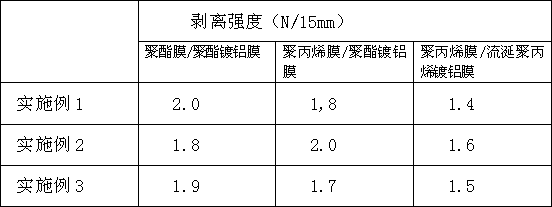

Examples

Embodiment 1

[0011] The preparation method of the main agent;

[0012] 1) Preparation of polyester polyol; put 0.9mol of ethylene glycol and diethylene glycol (ethylene glycol: diethylene glycol = 1:2) into the reaction kettle, add 0.2mol of terephthalic acid, stir and heat up, When the temperature rises to 180°C, add 82ppm of tetraisopropyl titanate catalyst and continue to heat up to 190°C. When the water produced in the reaction system reaches the theoretical amount, add trimethylpentanediol and neopentyl glycol for a total of 0.3 mol (trimethylpentanediol: neopentyl glycol = 2:1), 0.8 mol of phthalic anhydride and adipic acid (phthalic anhydride: adipic acid = 1:3), keep warm for 4 Hours, sampling after the heat preservation is over, when the acid value is 14mgKOH / g, and the hydroxyl value is 120mgKOH / g, turn on the vacuum pump, and when the vacuum degree reaches -0.098MPa, esterify and polycondense for 2 hours to obtain polyester polyol, take a sample for detection, The acid value is...

Embodiment 2

[0018] The preparation method of the main agent;

[0019] 1) Preparation of polyester polyol; put 0.85mol of ethylene glycol and diethylene glycol (ethylene glycol: diethylene glycol = 3:14) into the reaction kettle, add 0.2mol of terephthalic acid, stir and heat up, When the temperature rises to 180°C, 82ppm of tetraisopropyl titanate catalyst is added, and the temperature continues to rise to 190°C. When the water produced in the reaction system reaches the theoretical amount, trimethylpentanediol and neopentyl glycol are added for a total of 0.35 mol (trimethylpentanediol: neopentyl glycol = 2.5:1), isophthalic acid and adipic acid total 0.7mol (isophthalic acid: adipic acid = 2:5), continue to heat up to 230°C Insulate at ~235°C for 4 hours. After the end of the incubation, take samples for testing. When the acid value is 12mgKOH / g and the hydroxyl value is 115mgKOH / g, turn on the vacuum pump. When the vacuum reaches -0.098MPa, esterify and polycondense for 2 hours to obta...

Embodiment 3

[0025] The preparation method of the main agent;

[0026] 1) Preparation of polyester polyol; put 0.8mol of ethylene glycol and diethylene glycol (ethylene glycol: diethylene glycol = 1:15) into the reaction kettle, add 0.25mol of terephthalic acid, stir and heat up , when the temperature rises to 180°C, 82ppm of tetraisopropyl titanate catalyst is added, and the temperature continues to rise to 190°C. When the water produced in the reaction system reaches the theoretical amount, trimethylpentanediol and neopentyl glycol are added 0.4mol (trimethylpentanediol: neopentyl glycol = 1:1), isophthalic acid, phthalic anhydride and adipic acid total 0.75mol (isophthalic acid: phthalic anhydride: adipic acid = 2:1:4.5 ), continue to heat up to 230 ℃ ~ 235 ℃ and keep warm for 4 hours. After the heat preservation is over, take a sample test. When the acid value is 10.3mgKOH / g and the hydroxyl value is 112.0mgKOH / g, turn on the vacuum pump. When the vacuum reaches -0.098MPa After 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com