Method for advanced treatment of high-concentration chemi-mechanical pulp effluent by catalytic oxidation

A catalytic oxidation and chemical mechanical technology, applied in chemical instruments and methods, oxidized water/sewage treatment, processing wastewater treatment, etc., can solve the problems of high treatment cost, large content and large amount of sludge, and achieve rapid mixing. , the effect of reducing usage and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Table 1 Pollution characteristics of wastewater samples from a chemical mechanical pulp mill

[0025]

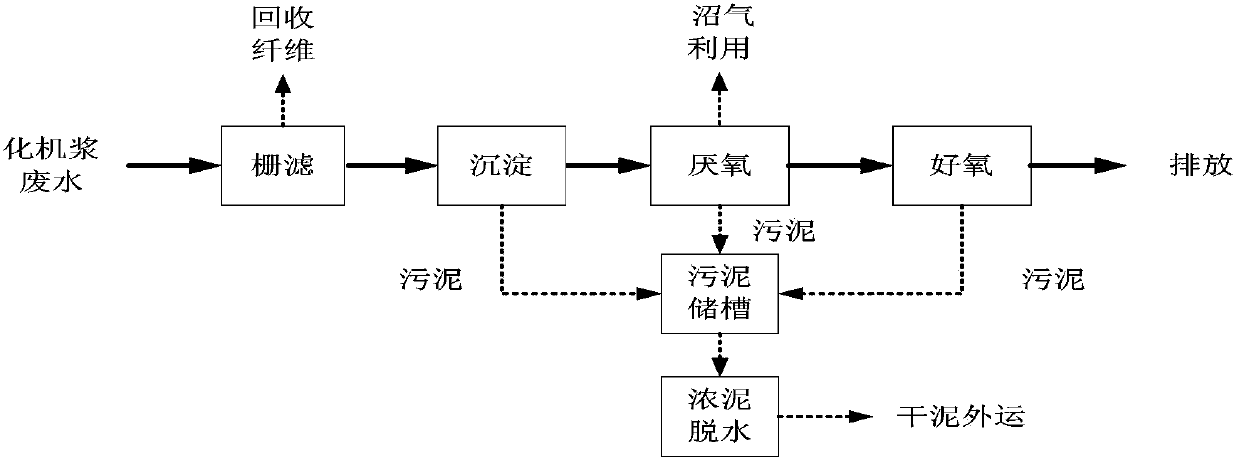

[0026] A chemical mechanical pulp mill discharges 3000-5000m of chemical mechanical pulp wastewater per day 3 , COD4500~6000mg / L, pollution characteristics are shown in Table 1. go through figure 1 After the precipitation-anaerobic-aerobic engineering treatment shown, the COD of the aerobic effluent is reduced to about 500mg / L.

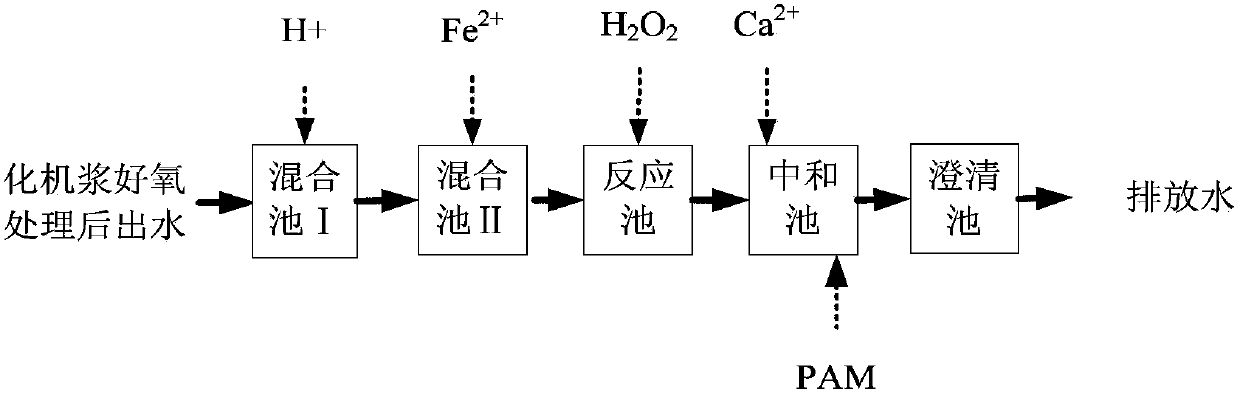

[0027] Direct use of aerobic treated effluent figure 2 The shown Fenton oxidation treatment, the specific steps are the effluent after aerobic treatment of chemical mechanical pulp wastewater, enter the mixing tank I and add concentrated sulfuric acid 0.40kg / m 3 ~0.75kg / m 3 , to reduce the pH of wastewater. Then enter the mixing pool II, add ferrous sulfate 0.40kg / m in the pool 3 ~0.80kg / m 3 . Then enter the reaction tank, add hydrogen peroxide 0.50kg / m in the reaction tank 3 ~0.70kg / m 3 . The flow rate of sulfuric acid enterin...

Embodiment 2

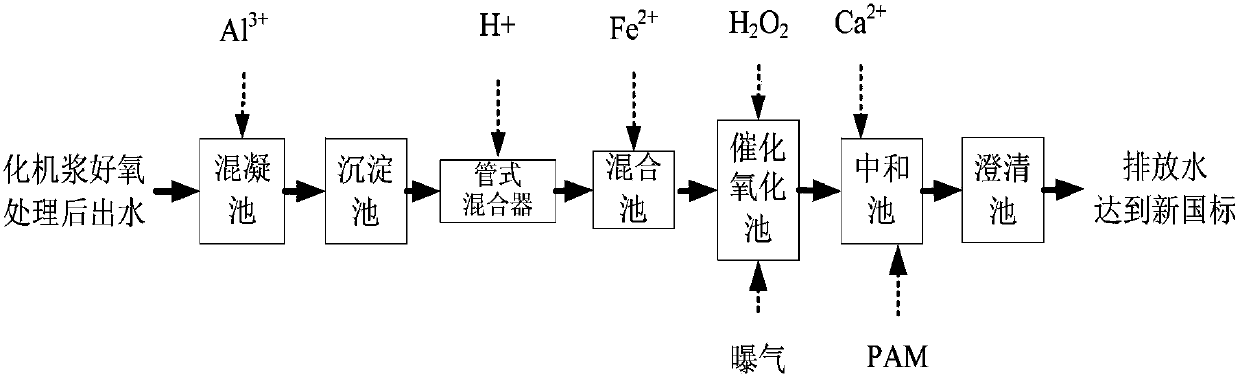

[0037] The waste water treatment site of a chemical mechanical pulp mill was upgraded, and a catalytic oxidation advanced treatment project was added. The process is as follows image 3 . Since July 2011, the government has implemented the new "Discharge Standards for Pulp and Paper Water Pollutants" (GB3544-2008), and conducted on-site monitoring of the advanced treatment project. The results are shown in Table 4. Judging from the one-month operation situation, the chemical mechanical pulp produced by the enterprise after aerobic treatment was 265-724 mg / L. After the advanced treatment of the catalytic oxidation project of the present invention, the COD of the total discharge outlet water was reduced to 31-87 mg / L (national standard heavy chromium Potassium acid method GB11914-89), or 36 ~ 89mg / L (on-line instrument monitoring), fully meet the national emission standards of COD ≤ 100mg / L.

[0038] Table 5 shows the material consumption and cost of catalytic oxidation advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com