Regenerated papermaking wastewater treatment system and process

A treatment process and a treatment system technology, which are applied in the field of waste paper and papermaking wastewater treatment systems and processes, and can solve problems such as the inability to apply waste paper and papermaking wastewater treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

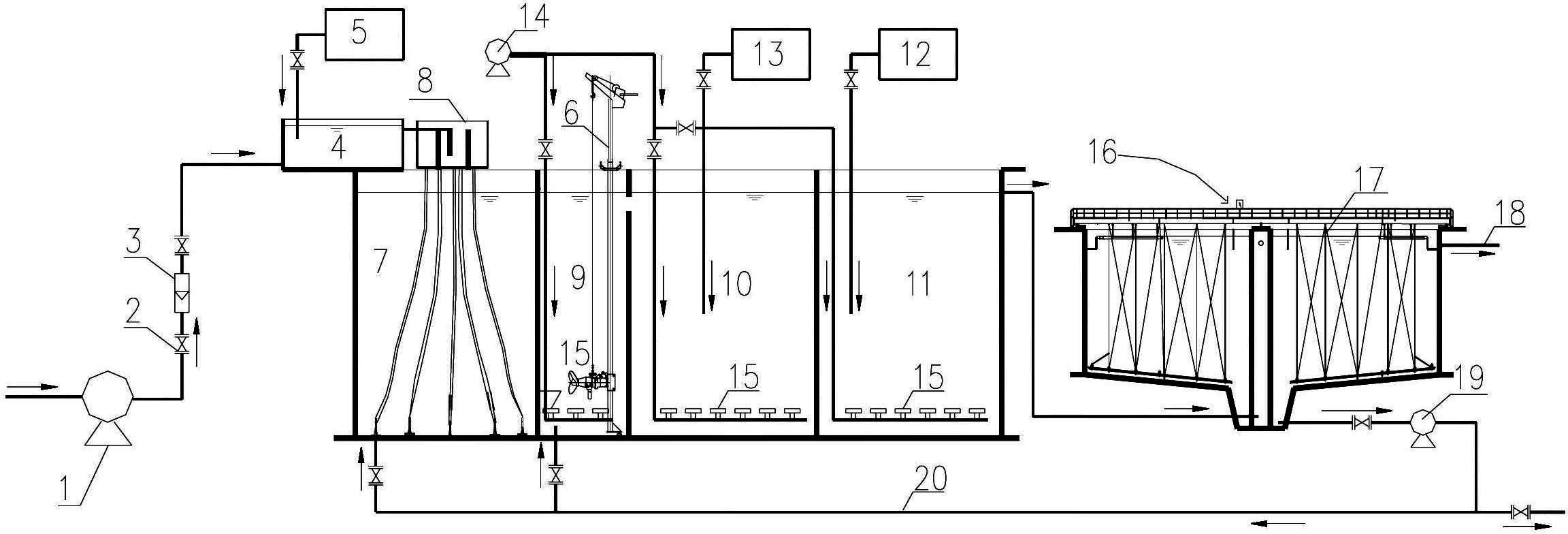

Embodiment 1

[0071] The water quality of a waste paper and papermaking sewage is pH: 7~8, CODcr: 1500~2500mg / l, SS: 500~800mg / l, and the inflow is 3000m 3 / d, the sewage treatment process is adjustment - air flotation - anaerobic hydrolysis - biological selection - aerobic decomposition - secondary sedimentation tank - effluent, and the effluent after treatment is required to meet the local standard of CODcr<100mg / l. The residence time of anaerobic hydrolysis is 12 hours. A submersible mixer is installed in the area to mix the mud and water fully, and a combined filler is installed to increase the biomass. Dosing 200mg / L iron salt in the air flotation tank, the residence time of the anaerobic treatment unit is 12 hours, the residence time of the biological selection unit is 1h, the residence time of the first aerobic treatment unit is 12 hours, and the residence time of the second aerobic treatment unit is 12 hours. for 8h. Activated sludge method, blast aeration, variable hole aeration h...

Embodiment 2

[0073] The wastewater in an industrial park is mainly waste paper and papermaking wastewater, the wastewater quality is pH6.5-8.5, CODcr:200-400mg / l, NH 3 -N: 5-10mg / l, TP0.5-1mg / l, SS: 150~300mg / l, water temperature is normal temperature, water volume is 40000m 3 / d, the sewage treatment process is: grille - sand settling - anaerobic hydrolysis - biological selection - aerobic decomposition - SBR - micro-flocculation sand filtration - ultraviolet disinfection - effluent, the effluent is required to meet the "urban sewage treatment plant pollution Class I B standard in GB18918-2002 emission standard. A submersible mixer is installed in the hydrolysis zone to mix the mud and water fully; the activated sludge method is adopted, the blast aeration is adopted, the residence time of the anaerobic treatment unit is 12 hours, the residence time of the biological selection unit is 1h, and the residence time of the first aerobic treatment unit is 8 hours, the residence time of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com