Injection-production two-trip pipe string balanced well killing control method

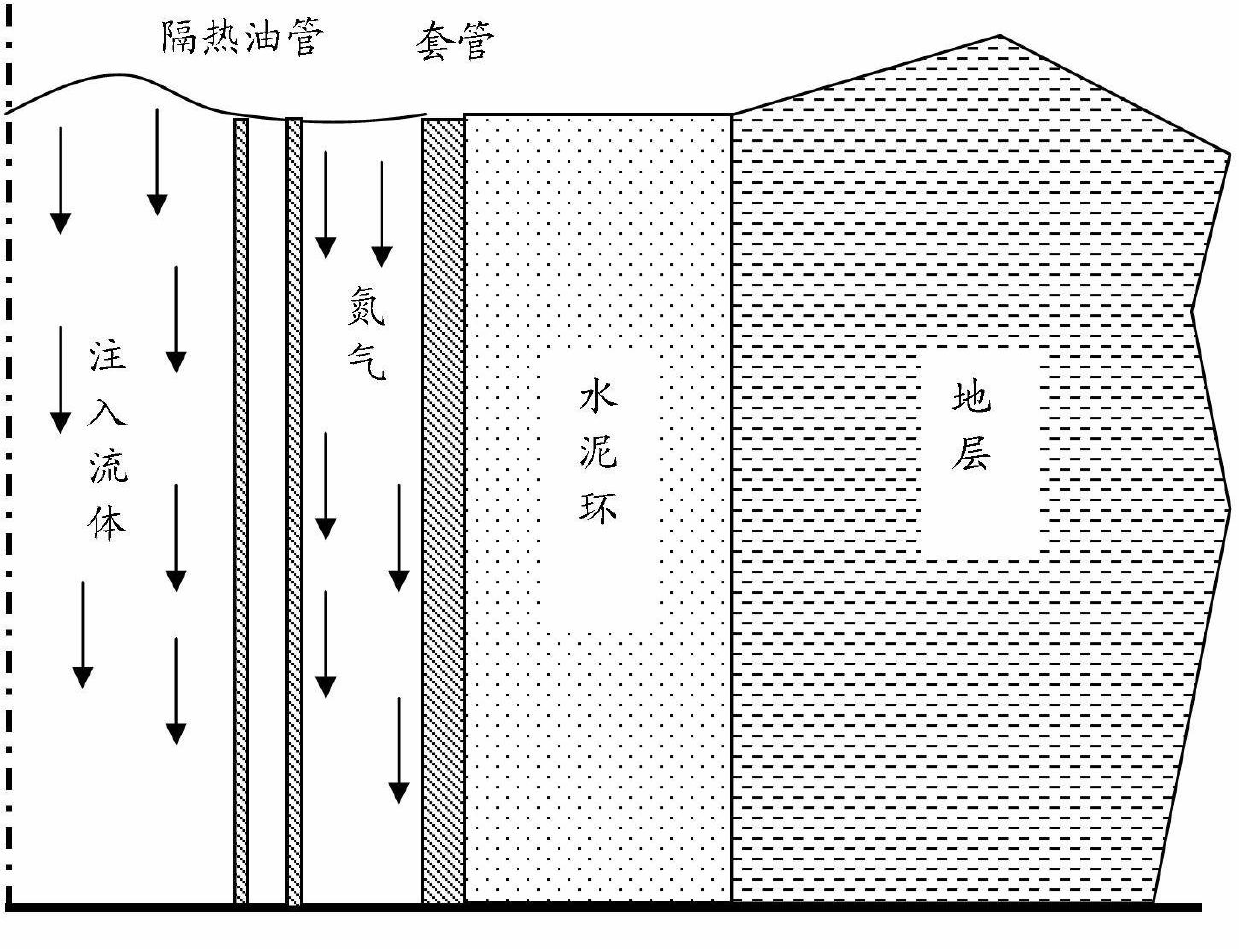

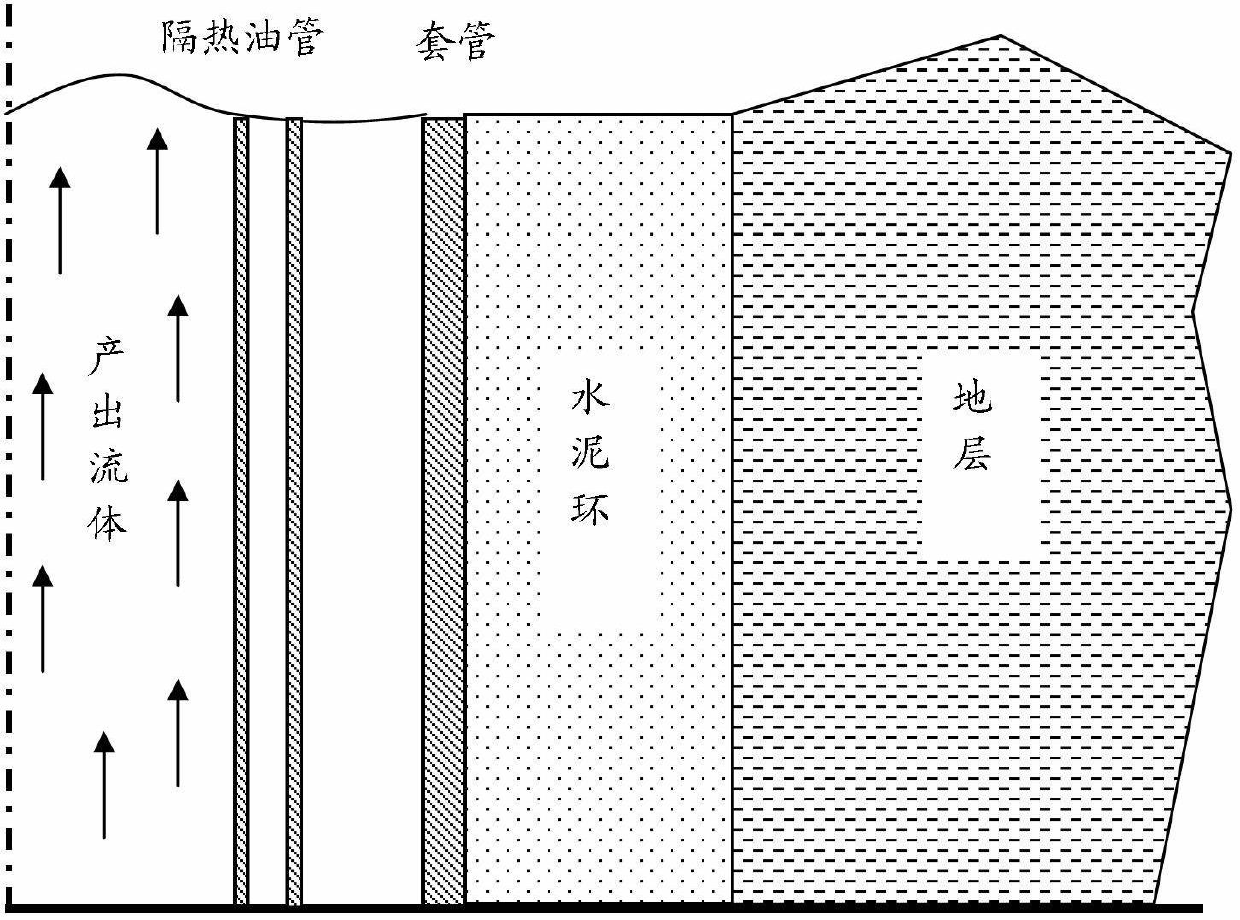

A control method and balanced pressure technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of lowering oil layer temperature, long killing operation time, increasing well killing fluid pollution and damage to the formation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

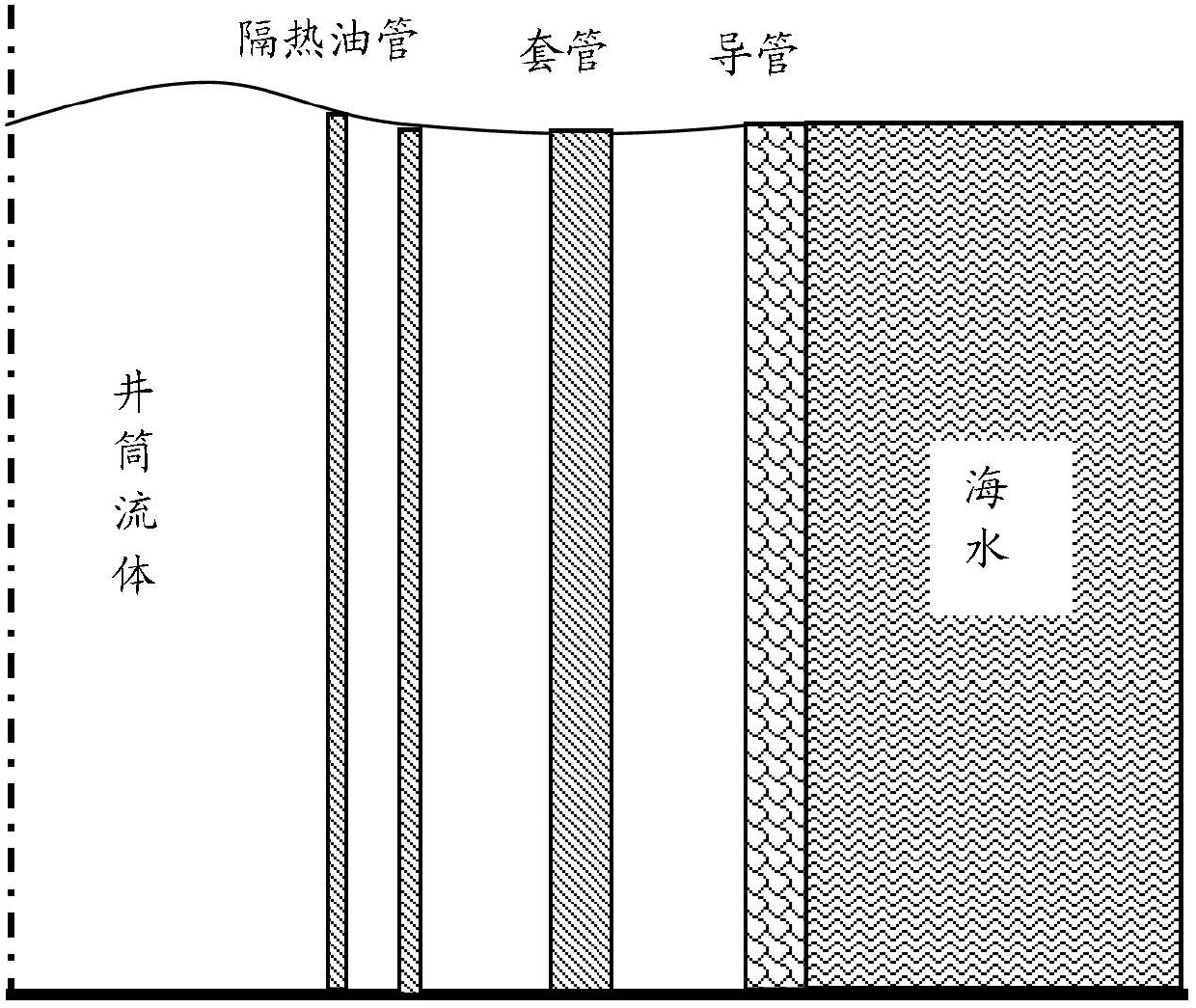

[0161] The general principle of the present invention will be described below by taking a multi-component thermal fluid huff and puff well located in an oilfield in Bohai Sea as an example.

[0162] Original formation data: original formation pressure 9MP a , the original formation temperature is 46°C, the supply radius is 600m, and the total geological reserves of the oilfield are 3×10 6 m 3 , original formation water storage 1×10 6 m 3 , oil layer depth 940m, formation thermal diffusivity 0.002m 2 / h, the specific heat of rock is 0.7KJ / (kg·℃), and the density of rock is 1900kg / m 3 , the thermal conductivity of rock is 2.4W / (m·℃);

[0163] Reservoir geophysical parameters: oil layer thickness 7m, permeability 4.56×10 -3 μm 2 , porosity 0.351, skin coefficient 0.38, formation crude oil viscosity 449mPa s, surface degassed crude oil density 0.92g / cm 3 , the original oil saturation is 0.7, the original water saturation is 0.2, the irreducible water saturation is 0.2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com