Thermal transfer ribbon used for edge crush type printer and preparation method thereof

A thermal transfer belt and printer technology, applied in printing, ink ribbon, inking device, etc., can solve the problems of short separation time interval between carbon ribbon and label, inability to achieve transfer effect, etc., to meet wear resistance, increase viscosity, etc. , The effect of clear transfer image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

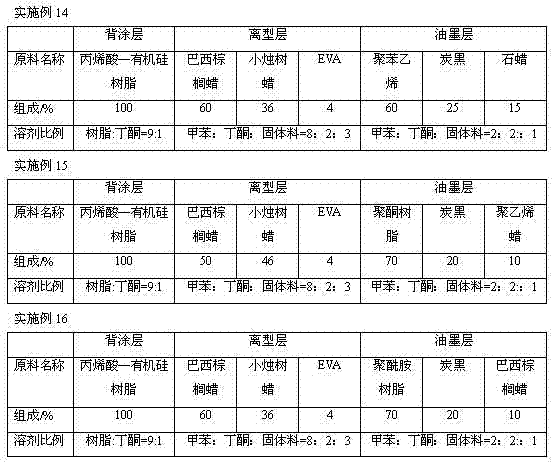

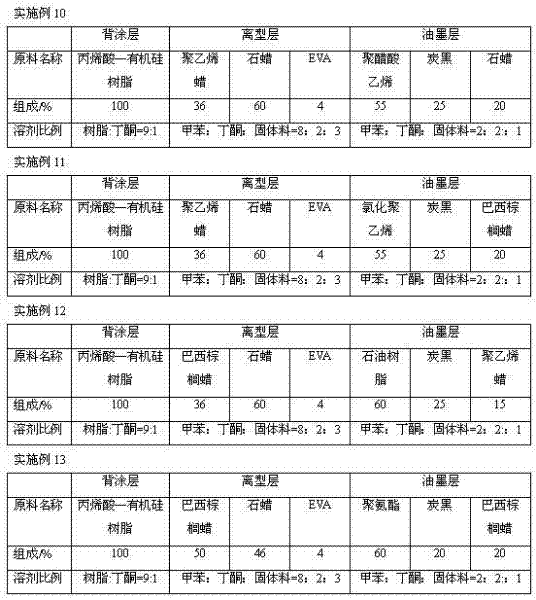

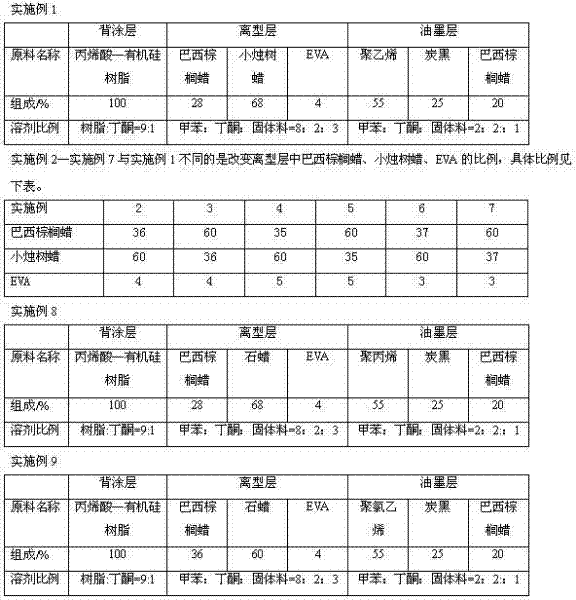

[0016] The following is the thermal transfer belt embodiment of the present invention for edge pressure printers, from top to bottom are ink layer, release layer, base film and back coating, the base film is polyester film, ink layer, release layer The composition of the type layer and the back coating is as follows:

[0017]

[0018]

[0019]

[0020] The resin in the backcoat in the embodiment 1-16 refers to acrylic-organic silicon resin, the solid material of the release layer refers to the total mass of wax and EVA, and the solid material of the ink layer refers to adhesive, carbon black and The total mass of wax; the VA content of ethylene-vinyl acetate copolymer (EVA) is 28~60%, and the melt index of ethylene-vinyl acetate copolymer is 2~300g / 10min.

[0021] The following steps are included in the preparation of the thermal transfer belts of Examples 1-16: (1) Preparation of the back coating: dissolve the acrylic-silicone resin in methyl ethyl ketone, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com