Long-lasting dripping anti-fog anti-aging agricultural film

An anti-aging and dripping technology, applied in applications, coatings, household appliances, etc., can solve problems such as the inability to guarantee dripping and anti-fogging functions, manpower, material resource consumption, poor control of connectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

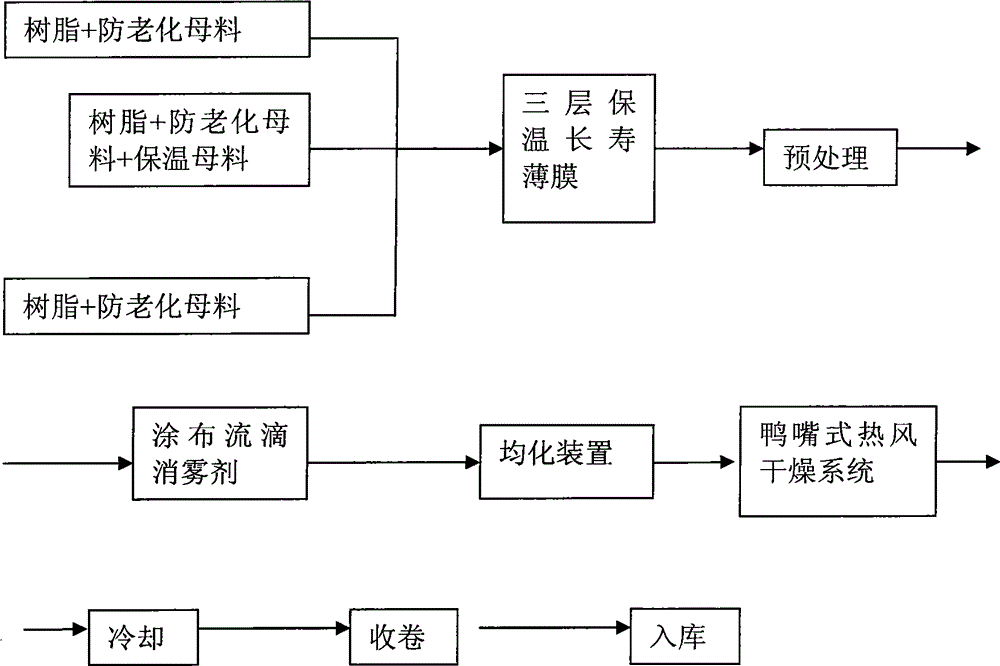

[0031] The one-step method of externally-coated inorganic nanometer water-soluble dripping anti-fog liquid is used to produce long-term dripping anti-fog heat preservation and anti-aging film. The production steps are as follows:

[0032] The first step: Mix 15Kg of light stabilizer and antioxidant with 90Kg polyethylene resin, and make an anti-aging masterbatch through a twin-screw extruder; pass 50Kg of hydrotalcite and 80Kg polyethylene resin through an internal mixer and a single screw The extruder makes hydrotalcite insulation masterbatch.

[0033] Step 2: Mix 200Kg LLPE 2045 and about 20Kg anti-aging masterbatch evenly, and then add them to the inner and outer layer feeding ports of the three-layer co-extrusion blown film unit; mix 100Kg mLPE 2005, 100Kg mLPE 2010, 20Kg insulation masterbatch is evenly mixed and then added to the middle feeding port of the three-layer co-extrusion film blowing unit. A tubular film is made by a three-layer co-extrusion blown film unit, c...

Embodiment 2

[0035] Embodiment 2, using the one-step method of externally coated inorganic nanometer water-soluble dripping anti-fog liquid to produce long-term dripping anti-fog heat preservation and anti-aging film, the production process is as follows:

[0036] The first step: mix 10Kg of light stabilizer and antioxidant with 85Kg polyethylene resin, and make an anti-aging masterbatch through a twin-screw extruder; pass 20Kg of hydrotalcite and 50Kg polyethylene resin through an internal mixer and a single screw The extruder makes hydrotalcite insulation masterbatch.

[0037] Step 2: Mix 200Kg of mLLPE 2010 and about 20Kg of anti-aging masterbatch evenly and add them to the inner and outer layer feeding ports of the three-layer co-extrusion film blowing unit; mix 100Kg of mLLPE2005, 100Kg of LLPE 2045 and 15Kg of anti-aging masterbatch Materials, 25Kg insulation masterbatch are evenly mixed and then added to the middle feeding port of the three-layer co-extrusion blown film unit. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com