Light emitting diode packaging structure

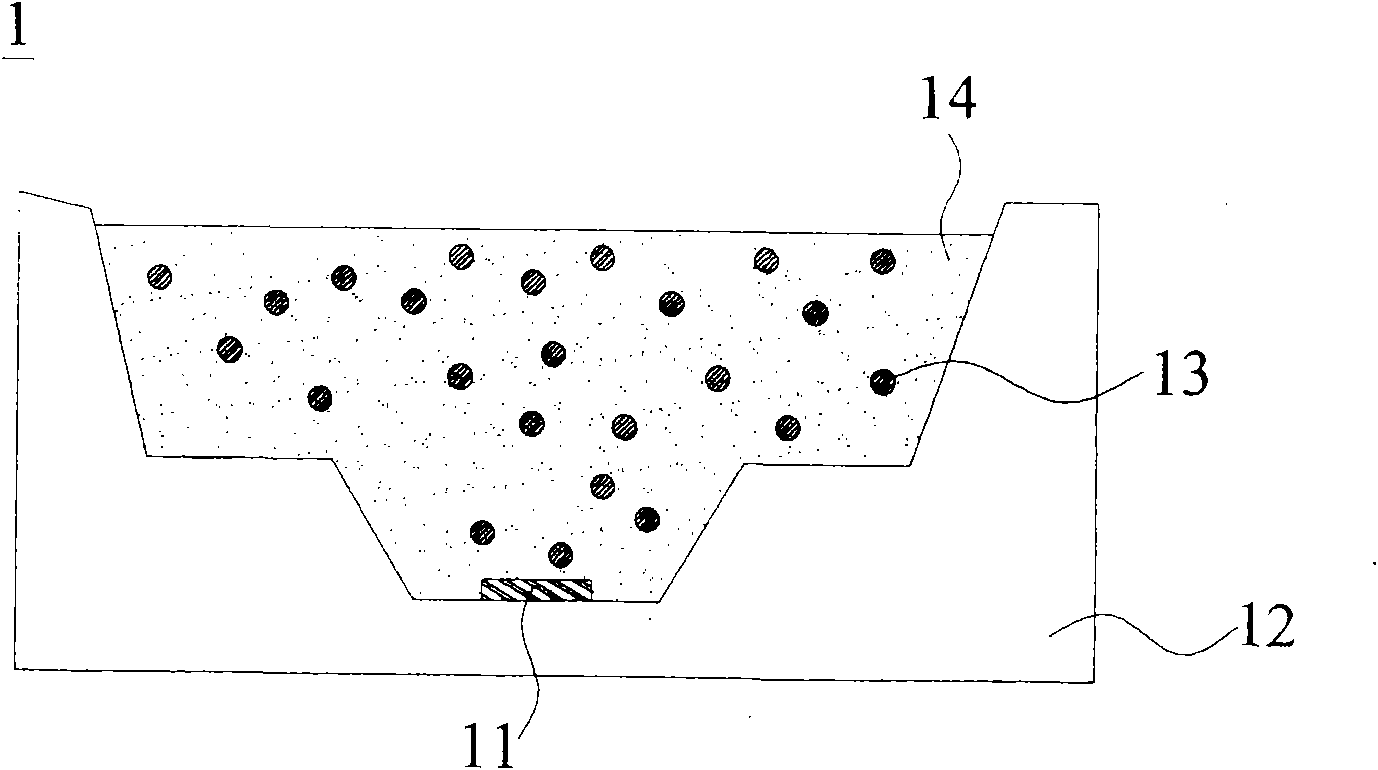

A light-emitting diode and packaging structure technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high target cost, inability to separate the base material, thin inside and thick outside, etc., and achieve the effect of uniform color temperature of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable your examiner to clearly understand the content of the invention, the following descriptions are provided with drawings, please refer to them.

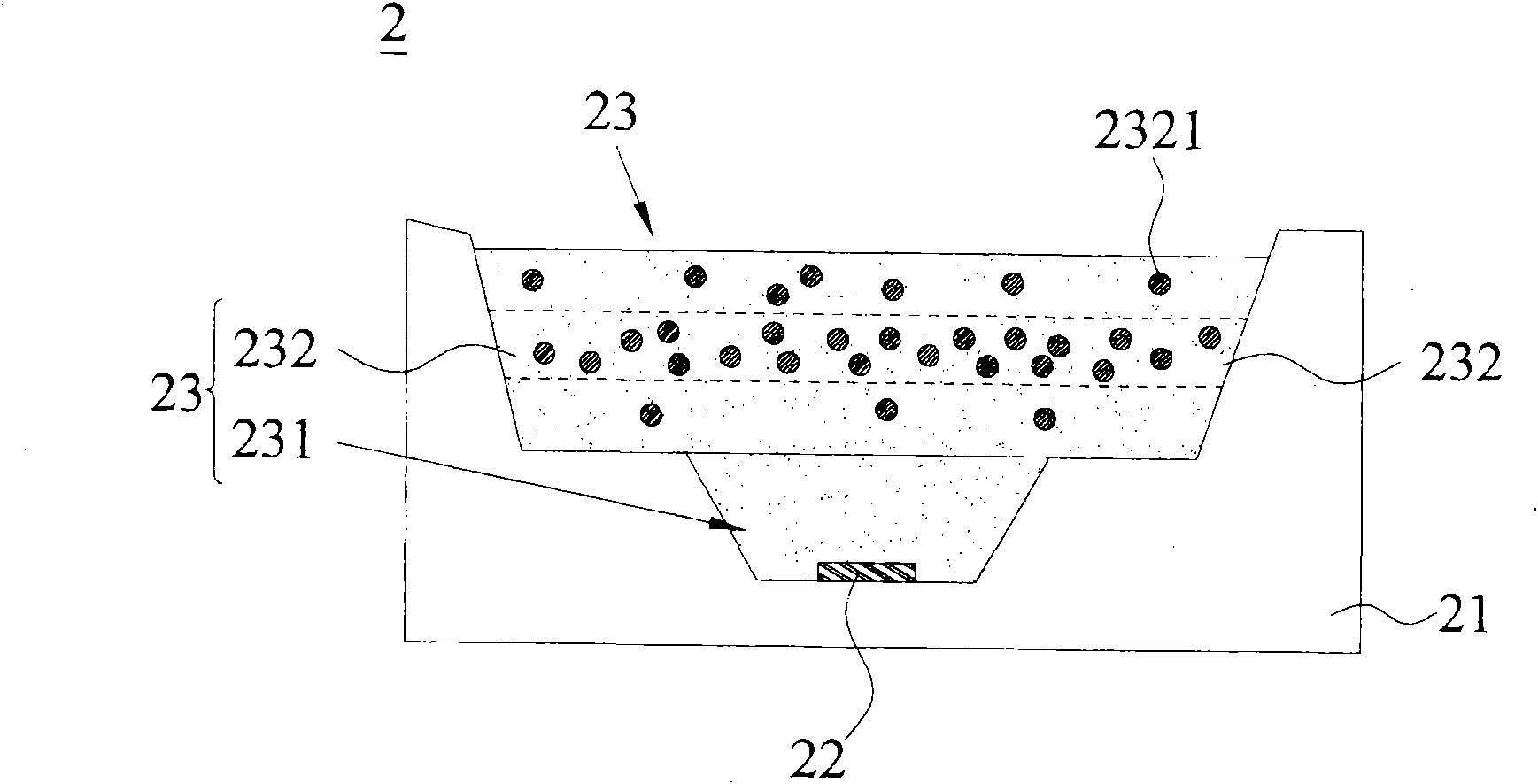

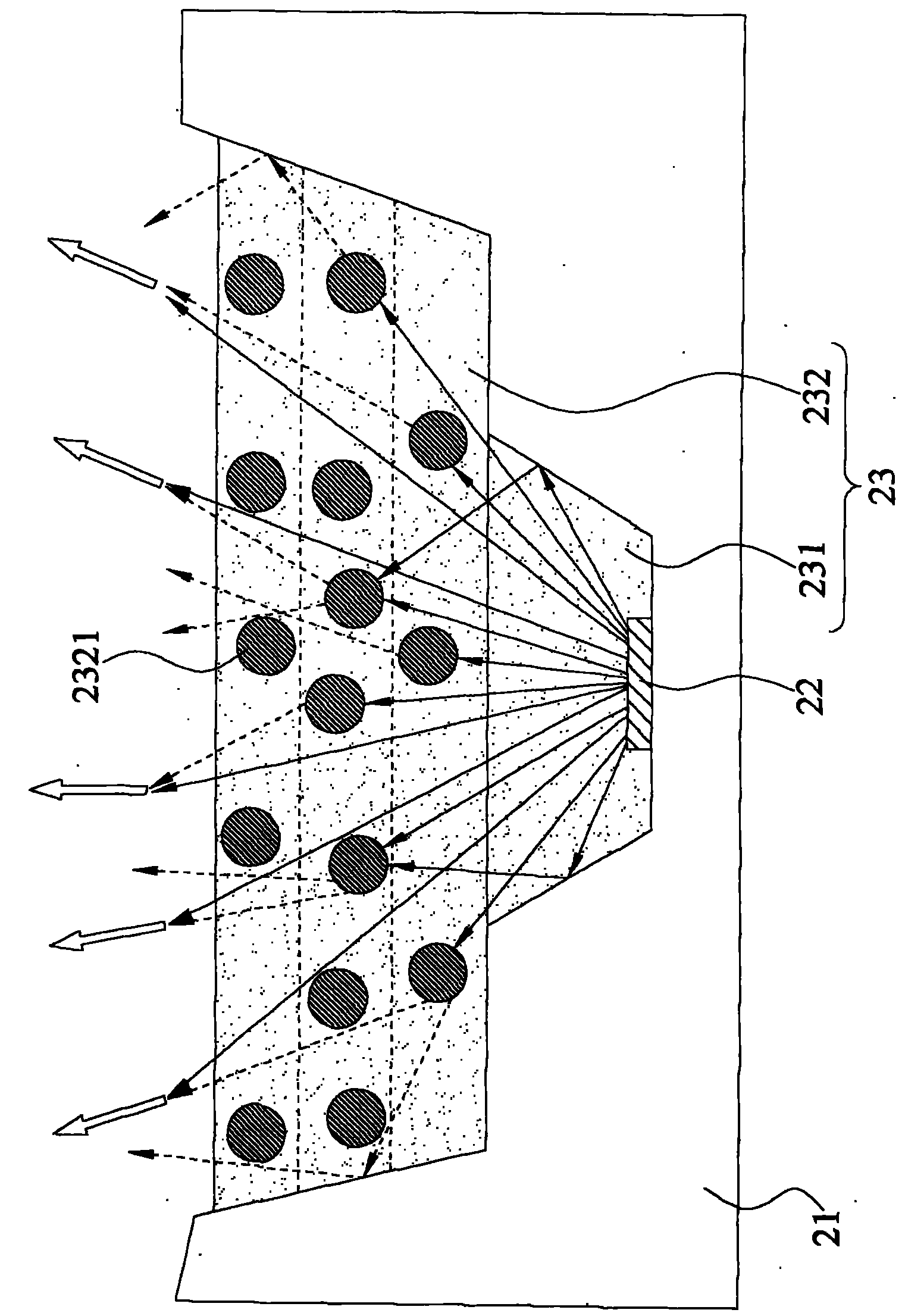

[0034] see figure 2 As shown, it is a schematic diagram of the first embodiment of the LED packaging structure of the invention. In the figure, the LED package structure 2 includes a base 21 , a LED chip 22 and a packaging compound 23 .

[0035] In this embodiment, the base 21 is an LED reflective cup. The light emitting diode chip 22 is a blue light emitting diode, which can emit a wavelength of about 450-460 nm after being driven, and is arranged on the bottom side of the base 21 . The encapsulant 23 includes a first optical adhesive 231 and a second optical adhesive 232 . The first optical adhesive material 231 can be epoxy resin (Epoxy) or silicone resin, and is coated on the LED chip 22 . The second optical adhesive material 232 can be epoxy resin (Epoxy) or silicone resin, and is disposed on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com