Online prediction system and method for density of powder injection molded blank

A technology of powder injection molding and prediction system, which is applied in the field of powder injection molding to achieve the effect of saving cost, improving efficiency and saving tedious labor

- Summary

- Abstract

- Description

- Claims

- Application Information

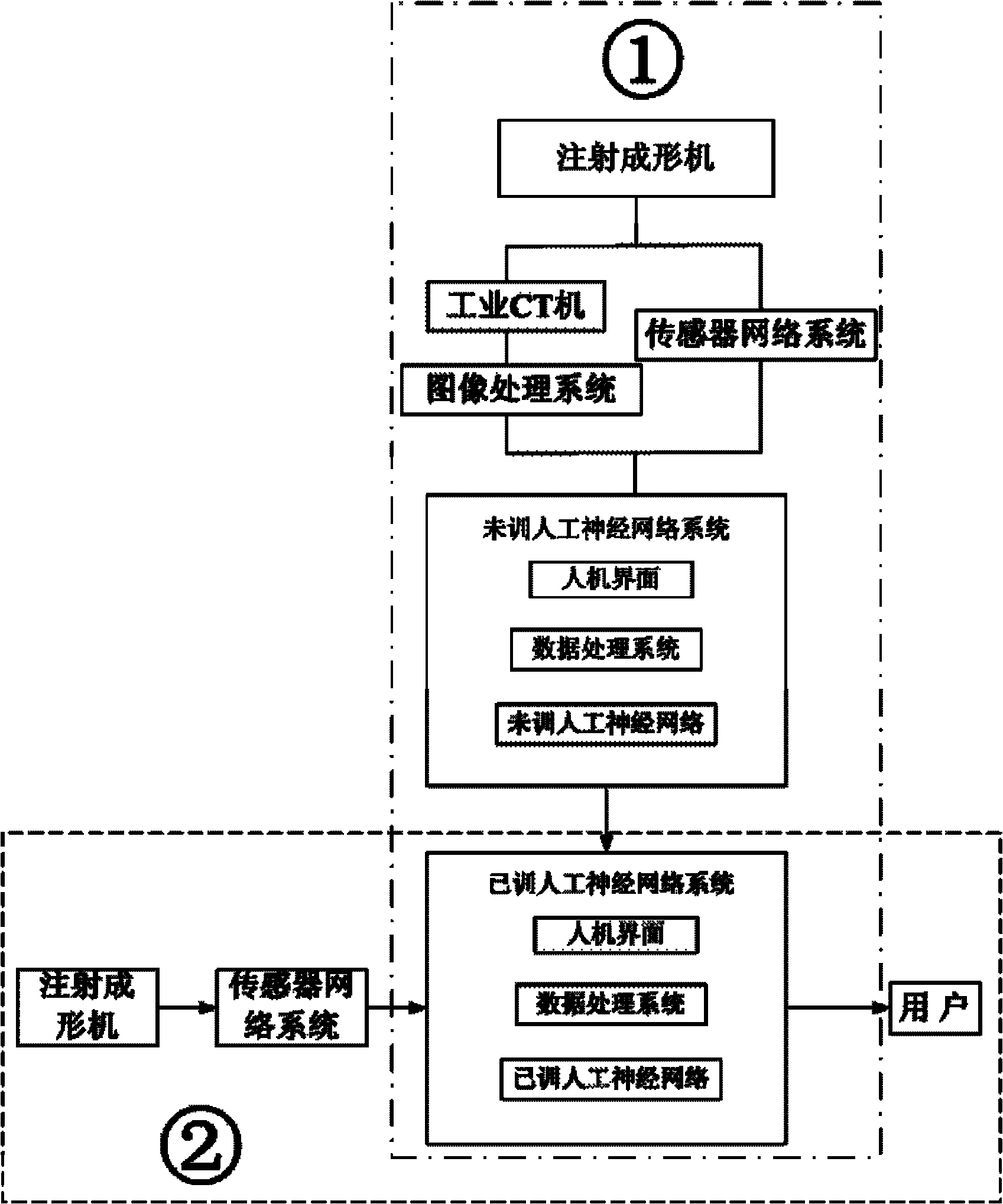

AI Technical Summary

Problems solved by technology

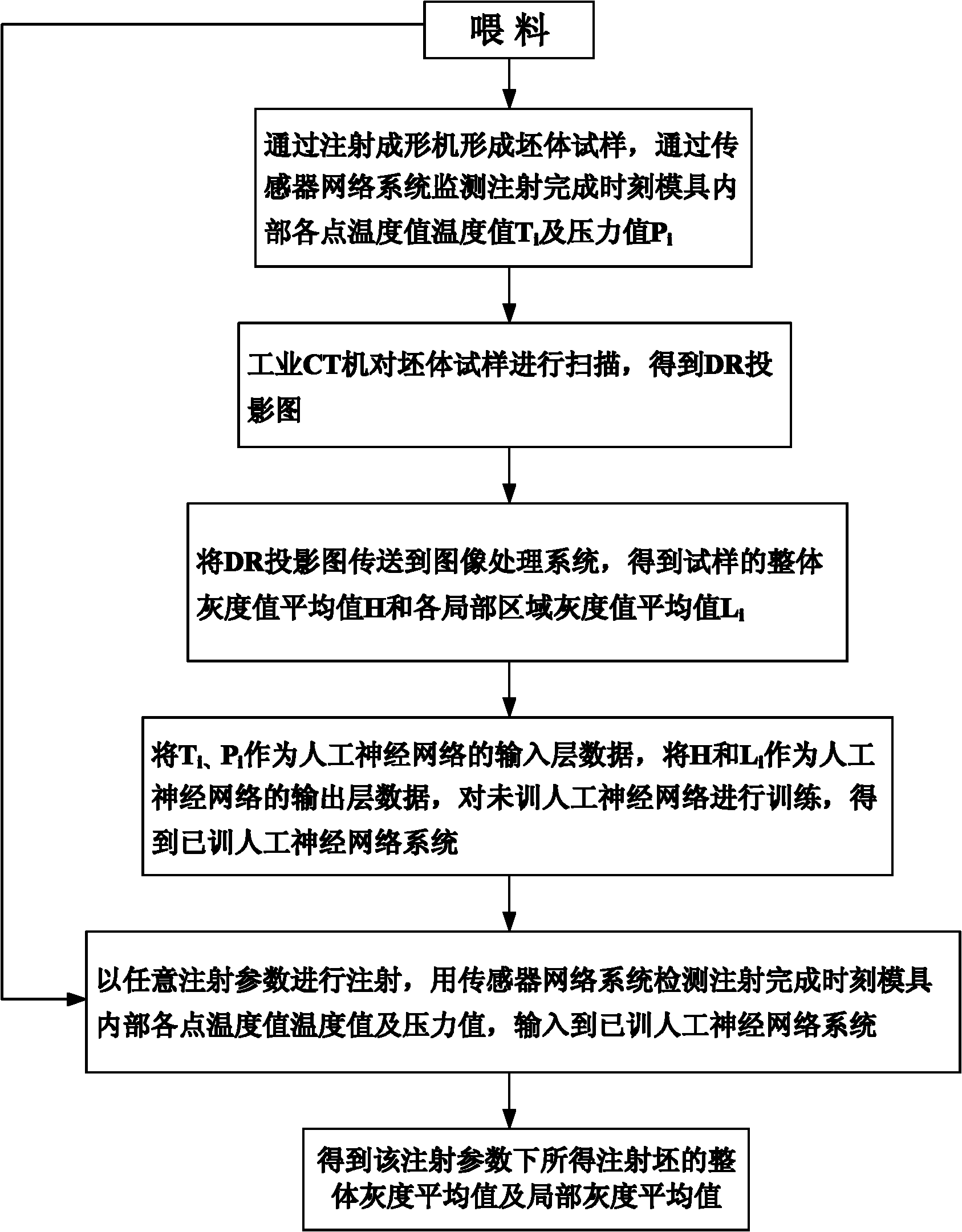

Method used

Image

Examples

Embodiment

[0041] Choose 316L stainless steel powder, the binder is 79% paraffin + 20% high-density polyethylene + 1% stearic acid, and the powder loading is 53%. The powder and binder were mixed at 140°C-150°C for 1.5h to obtain uniform feeding.

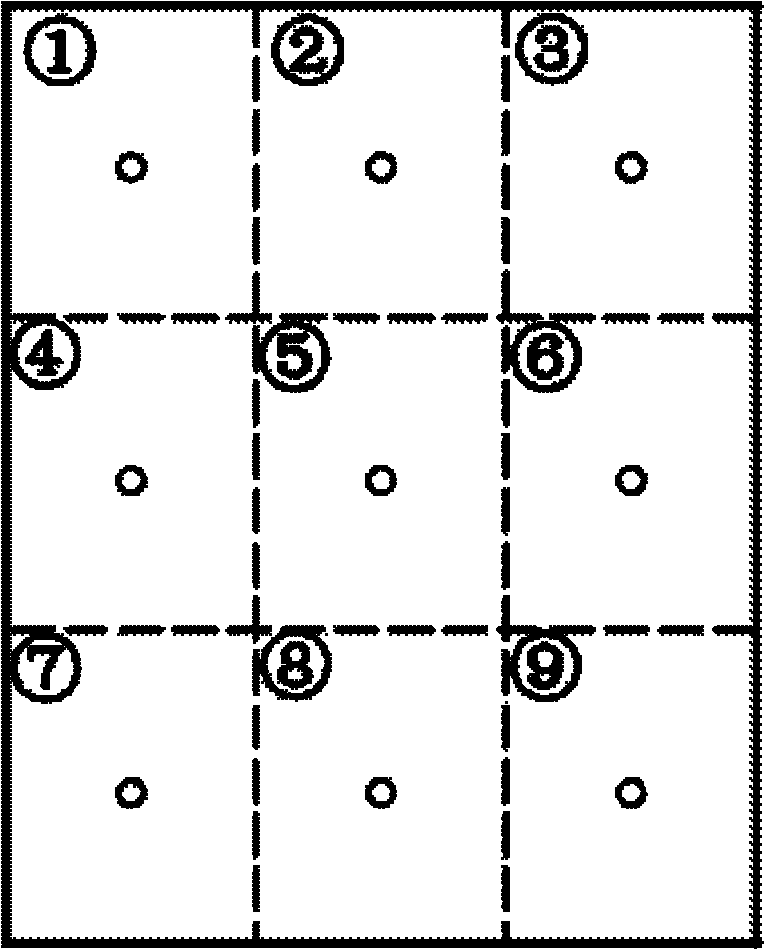

[0042] A cuboid sample is injected on an injection machine, and the mold size is 28.3mm×20mm×6mm. Use the following series of parameter combinations for injection, the mold temperature is kept at 300K; the injection temperature is between 420K and 450K, and an injection point is taken every 5K; the injection rate is 60cm 3 / S~90cm3 Between / S, every 2cm 3 / S interval to take an injection point. A cuboid sample was injected under each set of parameters, and a total of 1×2×16=32 injections were made to obtain 32 injection blank samples. At the same time, when each injection is completed, the temperature value T of each point inside the mold is monitored through the sensor network. i and pressure value P i .

[0043]

[0044] Put each in...

example 1

[0048] Example 1: Using a mold temperature of 300K, an injection temperature of 420K, and an injection rate of 63cm 3 / S Such a group of parameters is injected, and the temperature and pressure values of each point inside the mold are obtained through the monitoring of the sensor network system as follows: (T1, P1) = (419.5, 81.6); (T2, P2) = (421.3, 83.5); (T3, P3) = (419.5, 81.6); (T4, P4) = (420.0, 82.8); (T5, P5) = (422.5, 84.3); (T6, P6) = (420.0, 82.8); (T7 , P7) = (418.6, 80.6); (T8, P8) = (420.2, 83.0); (T9, P9) = (418.6, 80.6)

[0049] The data obtained from the above monitoring is normalized through the man-machine interface and then input to the artificial neural network system for grayscale prediction, and at the same time, the grayscale detection of the same sample is carried out through the industrial CT machine. The predicted and detected values are listed in the table below:

[0050]

[0051] It can be seen that the predicted value of the artifi...

example 2

[0052] Example 2: Using a mold temperature of 300K, an injection temperature of 422K, and an injection rate of 75cm 3 / S Such a group of parameters is injected, and the temperature and pressure values of each point inside the mold are obtained through the monitoring of the sensor network system as follows: (T1, P1) = (421.6, 82.2); (T2, P2) = (423.5, 84.3); (T3, P3) = (421.5, 82.2); (T4, P4) = (422.6, 83.5); (T5, P5) = (424.3, 84.8); (T6, P6) = (422.5, 83.6); (T7 , P7) = (419.8, 81.9); (T8, P8) = (421.3, 83.5); (T9, P9) = (419.8, 81.8)

[0053] The data obtained from the above monitoring is normalized through the man-machine interface and then input to the artificial neural network system for grayscale prediction, and at the same time, the grayscale detection of the same sample is carried out through the industrial CT machine. The predicted and detected values are listed in the table below:

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com