Ash removal device for heat exchange pipe of tail flue of boiler

The technology of tail flue and ash cleaning device is applied in the field of ash cleaning device for heat exchange tube of boiler tail flue, which can solve the problems of high energy consumption, economic loss of power plants and factories, long operation period, etc. The effect of low investment cost and short cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

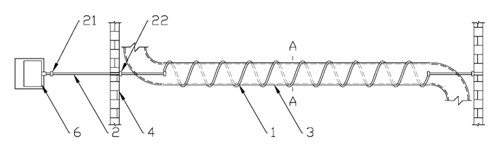

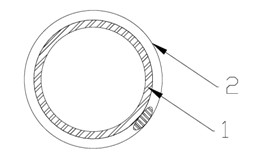

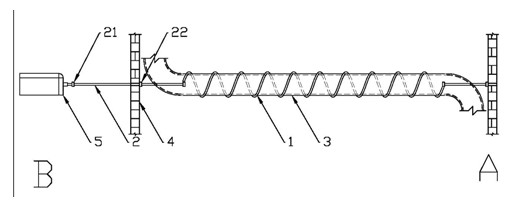

[0025] The boiler tail flue heat exchange tube soot cleaning device of the present invention comprises a coil spring 1 and a pull rod 2, the axial direction of the pull rod 2 is parallel to the stretching direction of the coil spring 1, one end of the pull rod 2 is connected with one end of the coil spring 1, and the coil spring 1 is wound on the outside of the cleaned heat exchange tube 3, and the tie rod 2 passes through the flue wall 4 of the boiler where it is located. A second blocking and sealing plate 22 is provided on the rod section inside the wall 4 .

[0026] In an embodiment of the present invention, there is one pull rod 2 , and the end of the coil spring 1 not connected to the pull rod 2 is fixed inside the flue wall 4 .

[0027] In another embodiment of the present invention, the two ends of the coil spring 1 are respectively connected with a pull rod 2, and the dust cleaning operation process is carried out at both ends in sequence during operation, and the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com