Transparent thermal insulation material and preparation method thereof

A heat-insulating material and transparent technology, applied in radiation-absorbing coatings, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve problems such as complex manufacturing processes, and achieve long-term quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

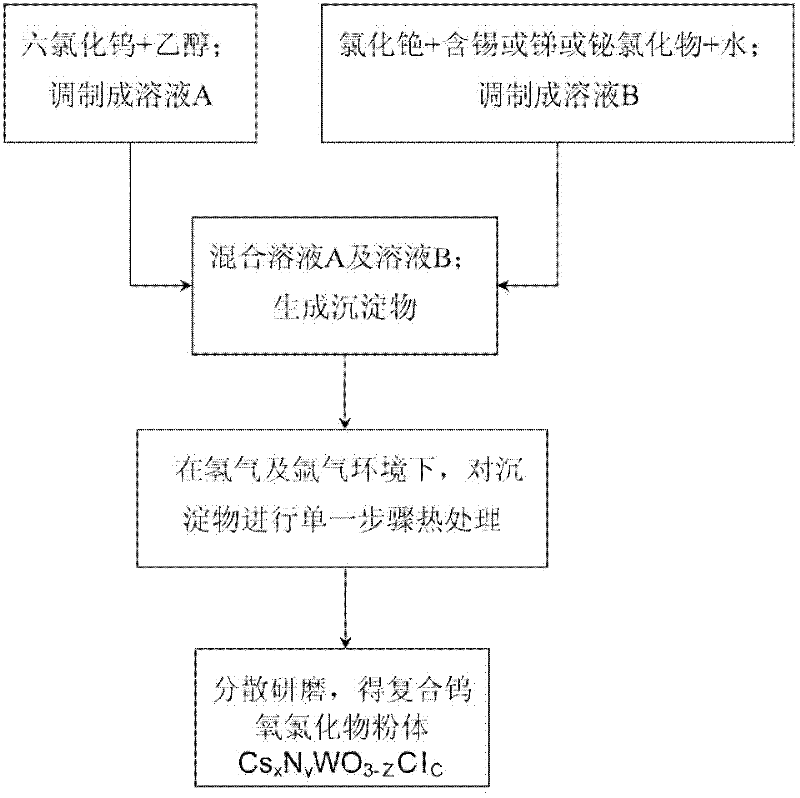

Method used

Image

Examples

Embodiment 1

[0071] Mix tungsten hexachloride and ethanol to prepare a blue solution A with a pH value of about 0; additionally take cesium chloride (CsCl) and antimony trichloride (SbCl) 3 ) were mixed together with water in a ratio of 1 mole to 0.1 mole to prepare clear solution B. The two solutions of A and B were co-deposited to produce precipitates. The chemical reaction formula is as follows:

[0072] 2WCl 6 +C 2 h 5 OH+3H 2 O→WOCl 4 ↓+WO 2 Cl 2 ↓+6HCl+C 2 h 5 OH;

[0073] WOCl 4 ↓+WO 2 Cl 2 ↓+C 2 h 5 OH+CsCl+SbCl 3 +3H 2 O→2WO 3 ↓+Cs + +Sb +3 +Cl - +6HCl+C 2 h 5 Oh.

[0074] Next, the obtained precipitate was placed in a high-temperature furnace, and a certain flow rate of argon and hydrogen was introduced. Under the condition that the temperature increase rate of the high-temperature furnace was 2°C per minute, the high-temperature furnace was raised from room temperature to 485-485°C. 515°C (expressed as an average temperature of 500°C), and heat treatment...

Embodiment 2

[0080] With embodiment 1, but get cesium chloride and antimony trichloride (SbCl 3 ) were mixed together with water in a ratio of 1 mole to 0.5 mole to prepare clear solution B.

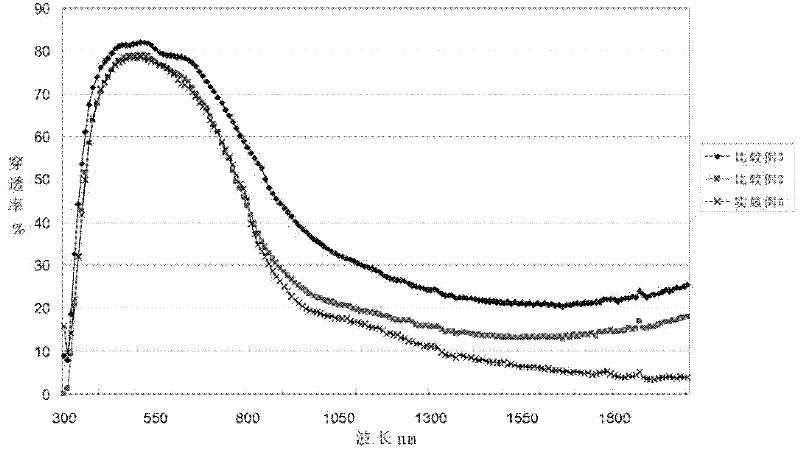

[0081] The transmittance of the prepared transparent heat-insulating film to a wavelength of 300-2000 nm was measured, and the results are listed in Table 1.

Embodiment 3

[0083] With embodiment 2, but use tin trichloride (SnCl 3 ) to replace antimony trichloride (SbCl 3 ) to prepare a transparent solution B.

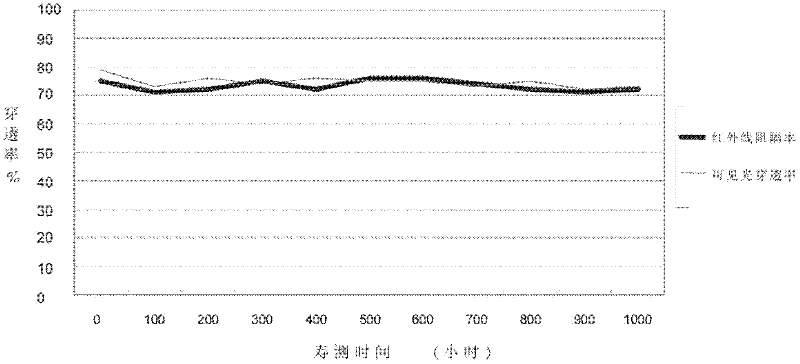

[0084] The transmittance of the prepared transparent heat-insulating film to a wavelength of 300-2000nm was measured, and the results are listed in Table 1; the results of the life test trend chart are listed in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com