Polymer-sylvite-carbon nanotube composite membrane material and preparation method thereof

A technology of carbon nanotube composite and carbon nanotube, which is applied in the field of high dielectric composite film materials, achieves the effect of low cost, simple process and convenient large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

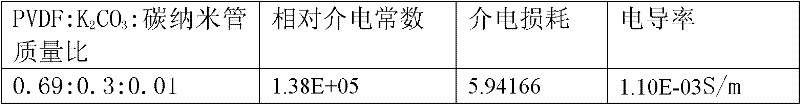

Embodiment 1

[0036] The polymer polyvinylidene fluoride, potassium carbonate, and carbon nanotubes are weighed according to their mass ratio of 0.69:0.3:0.01 as raw materials, and the weighed raw materials are placed in a nylon ball mill tank, using absolute ethanol as a medium, in a conventional ball mill Go up the ball mill for 16 hours, take out the slurry after ball milling and dry it in a constant temperature drying oven at 80°C to form a mixed powder; add 20ml of organic solvent N,N-dimethylformamide (DMF ) to obtain a mixed liquid; heat the mixed liquid to 50°C on a magnetic stirrer, stir to dissolve PVDF completely; then use an ultrasonic oscillator to ultrasonically vibrate to K 2 CO 3 and carbon nanotubes are evenly dispersed in the mixed liquid to obtain a composite liquid, and then the obtained composite liquid is poured on a flat glass sheet cleaned by deionized water and absolute ethanol to make it evenly cast; the glass loaded with the composite liquid Place the sheet in a ...

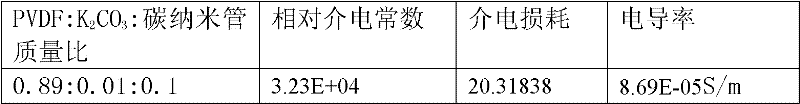

Embodiment 2

[0040] The polymer polyvinylidene fluoride, potassium carbonate, and carbon nanotubes are weighed according to their mass ratio of 0.89:0.01:0.1, and the weighed raw materials are placed in a nylon ball mill tank, and absolute ethanol is used as a medium, in a conventional ball mill Ball mill for 24 hours, take out the ball-milled slurry and dry it in a constant temperature drying oven at 80°C, add 10ml of organic solvent N, N-dimethylformamide (DMF) to the dried mixed powder to obtain a mixed Liquid, heat the mixed liquid to 70°C on a magnetic stirrer, stir to completely dissolve the PVDF in the mixed liquid; then use an ultrasonic cleaner to ultrasonically vibrate to K 2 CO 3 and carbon nanotubes are uniformly dispersed in the mixed liquid to obtain a composite liquid, and then the obtained composite liquid is poured on a flat glass sheet cleaned by deionized water and absolute ethanol to make it uniformly cast; the glass loaded with the composite liquid Place the sheet in ...

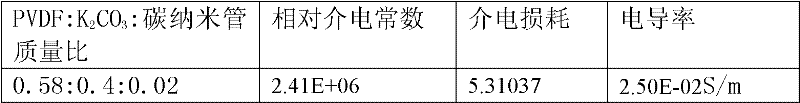

Embodiment 3

[0044] The polymer polyvinylidene fluoride, potassium carbonate, and carbon nanotubes are weighed according to their mass ratio of 0.58:0.4:0.02, and the weighed raw materials are placed in a nylon ball mill tank, and absolute ethanol is used as a medium to grind the raw materials in a conventional ball mill Ball milled for 6 hours; the slurry after ball milling was taken out and dried in a constant temperature drying oven at 80°C, and 15ml of organic solvent N, N-dimethylformamide (DMF) was added to the dried mixed powder to obtain a mixed liquid; heat the mixed liquid to 80°C on a magnetic stirrer, stir to completely dissolve the PVDF in the mixed liquid; then use an ultrasonic cleaner to ultrasonically vibrate to K 2 CO 3 and carbon nanotubes are uniformly dispersed in the mixed liquid to obtain a composite liquid, and then the obtained composite liquid is poured on a flat glass sheet cleaned by deionized water and absolute ethanol to make it uniformly cast; the glass loade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com