Polysiloxane for semiconductor packaging adhesive

A polysiloxane and encapsulant technology, applied in adhesives, other chemical processes, chemical instruments and methods, etc., can solve the problems of poor light transmittance, yellowing, and brittle epoxy resin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] 1. Preparation of polysiloxane A

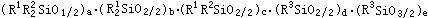

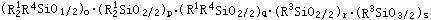

[0033] The present invention relates to the general structural formula of polysiloxane A:

[0034]

[0035] Where R 1 Is an alkyl group, such as methyl, ethyl, propyl, butyl, etc., preferably methyl; R 2 Is an alkyl or alkenyl group, such as methyl, vinyl, allyl, butenyl, etc., preferably vinyl; R 3 It is an aryl group, such as phenyl, tolyl, naphthyl, etc., preferably phenyl. a+b+c+d+e=100, a=1~20, b=0~20, c=0~20, d=0~20, e=30~60.

[0036] The present invention relates to a preparation method of polysiloxane A: adding catalyst, solvent, end-capping agent, methylsiloxane, methylvinylsiloxane, and phenylsiloxane dropwise while stirring at room temperature or under heating Phenyltrialkoxysilane, after dripping the phenyltrialkoxysilane, react at room temperature or heating for 3~18 hours, stand still, separate the upper acid water, wash the lower oil phase with water, and wash the oil phase to the middle After removing the low component at 1...

Embodiment 1

[0044] Put 20g of 30% sulfuric acid, 54g of toluene, 40g of hexamethyldisiloxane, 22g of octamethylcyclotetrasiloxane and 26g of tetramethyltetravinylcyclotetrasiloxane into a four-necked flask, start stirring, Slowly add phenyltrimethoxysilane dropwise, after dropping 178g of phenyltrimethoxysilane, react at room temperature for 18 hours, stand still, separate the upper acid water, wash the lower oil phase with water, and wash the oil phase to neutral , And then unplug the low distillate at 150°C and -0.099Mpa to obtain a colorless and transparent product A1.

Embodiment 2

[0046] Put 25g of 30% sulfuric acid, 107g of toluene, 30g of hexamethyldisiloxane, 88g of dimethyldimethoxysilane and 49g of tetramethyltetravinylcyclotetrasiloxane into a four-necked bottle, and set it to reflux Turn on the tube, stir, and start adding phenyltrimethoxysilane slowly. After dropping 400g of phenyltrimethoxysilane, stir at room temperature for 16 hours, then stand still, separate the upper layer of acid water, and wash the lower oil phase with water , Wash the oil phase to neutral, then pull out the low distillate at 150°C and -0.099Mpa to obtain a colorless and transparent product A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com