Environmental-friendly black glaze for automotive glass and preparation method of black glaze

An automotive glass and environmental protection technology, which is applied in the field of black glaze for high-performance environmental protection automotive glass and its preparation, can solve the problem of high glass cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

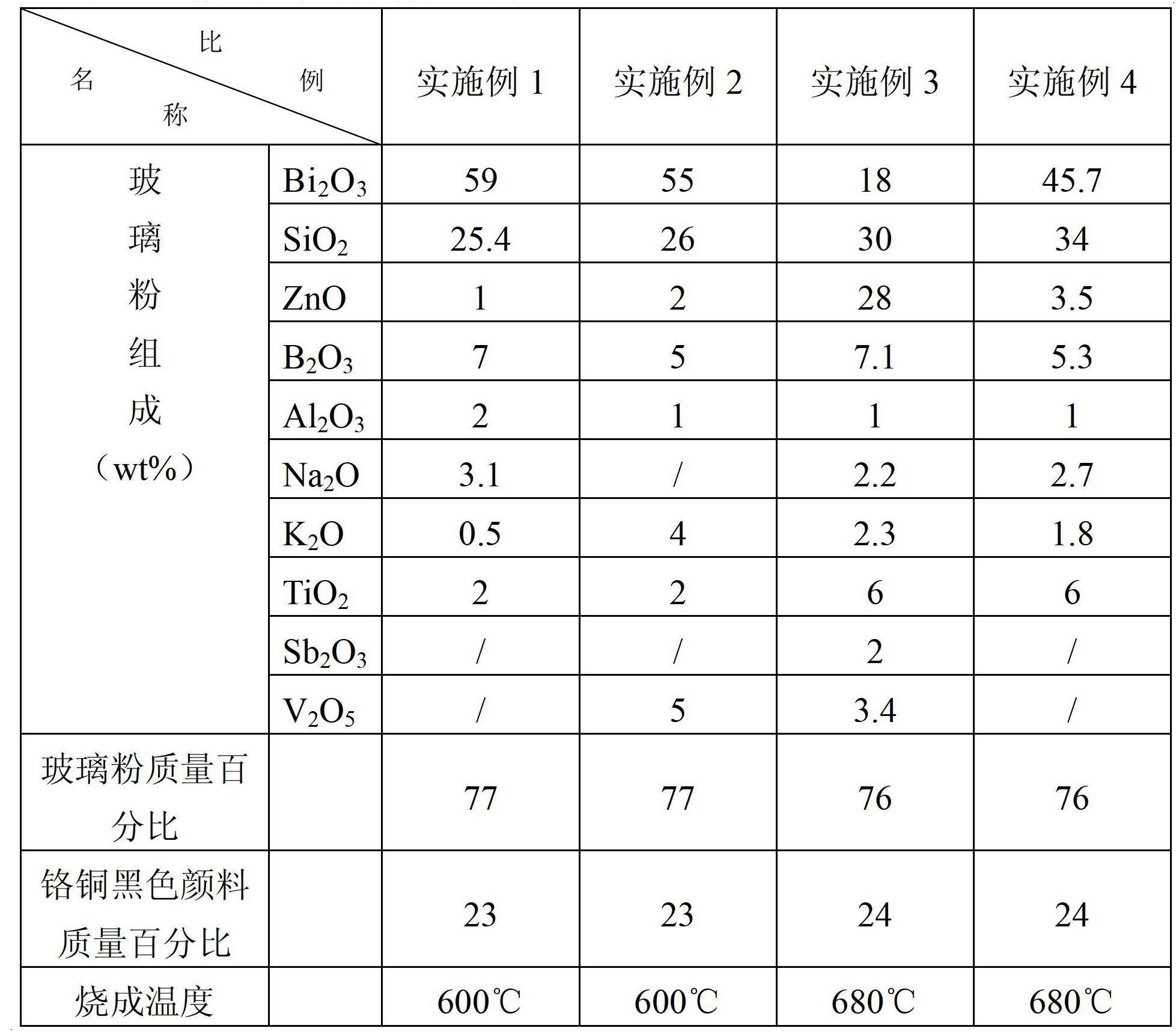

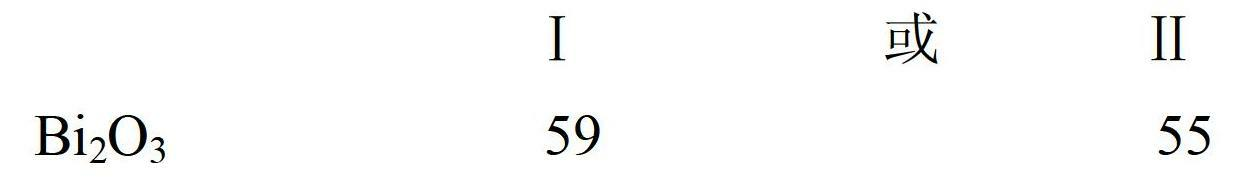

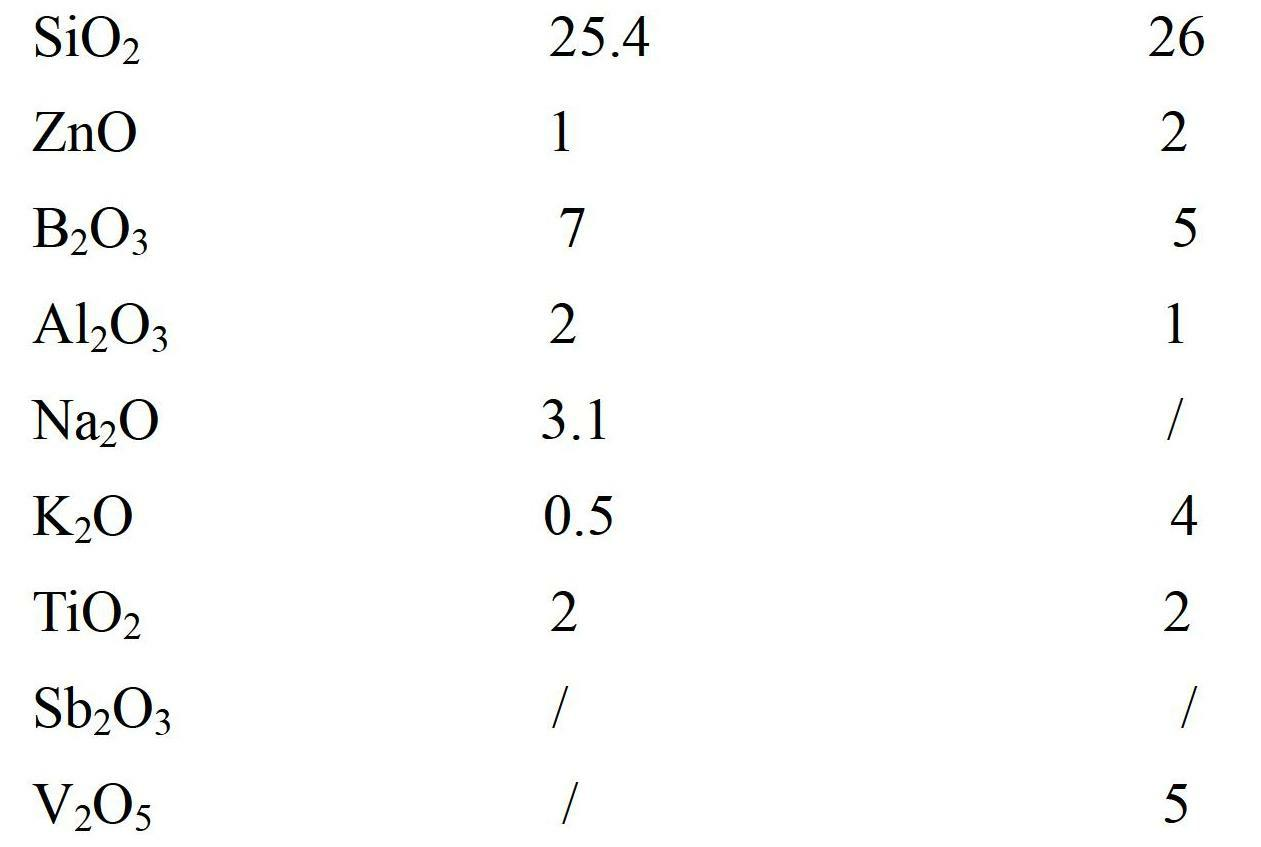

[0022] The embodiments of the black glaze for high-performance environment-friendly automobile glass of the present invention are summarized in Table 1

[0023] Table 1: Concrete composition of each embodiment

[0024]

[0025] The black glazes of the above-mentioned embodiments can be used alone or mixed in a certain proportion.

[0026] Above-mentioned embodiment 1 and embodiment 2 are used for front windshield, and embodiment 3 and embodiment 4 are used for rear windshield. The black glaze produced by each of the above-mentioned embodiments satisfies after firing:

[0027] (1) The coefficient of thermal expansion is (85-95)×10 -7 / °C;

[0028] (2) Acid resistance meets the requirements: soak at 80°C 0.1NH 2 SO 4 More than or equal to 40 hours black glaze does not change color;

[0029] (3) Blackness value L<7;

[0030] (4) Shielding △L<1;

[0031] (5) The anti-adhesive performance of the black glaze on the rear windshield meets the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com