Electrochemical removal method for heavy metals in breeding circulating seawater

A heavy metal and electrochemical technology, applied in the electrochemical removal of mercury, zinc, cadmium, heavy metal copper and lead in aquaculture circulating seawater, can solve problems such as pollution of aquaculture aquatic products, and achieve simple and cheap equipment, moderate mechanical strength, and high reliability. Strong control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] In this embodiment, the technical content of the present invention is further explained by removing heavy metals from the circulating water of industrialized culture of turbot.

[0044] The electrochemical removal method of heavy metals in aquaculture circulating seawater specifically comprises the following steps:

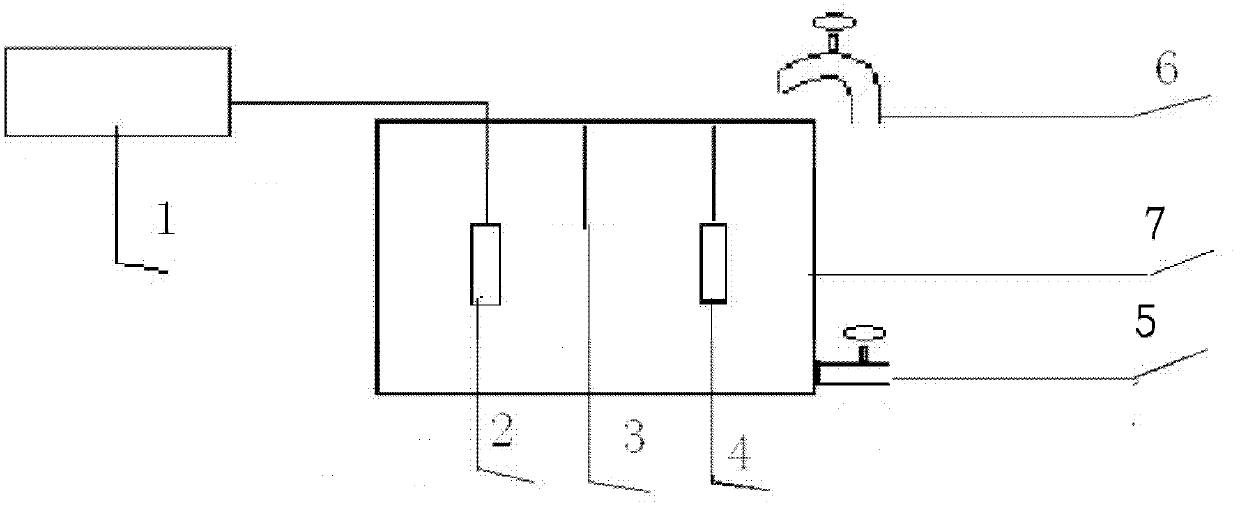

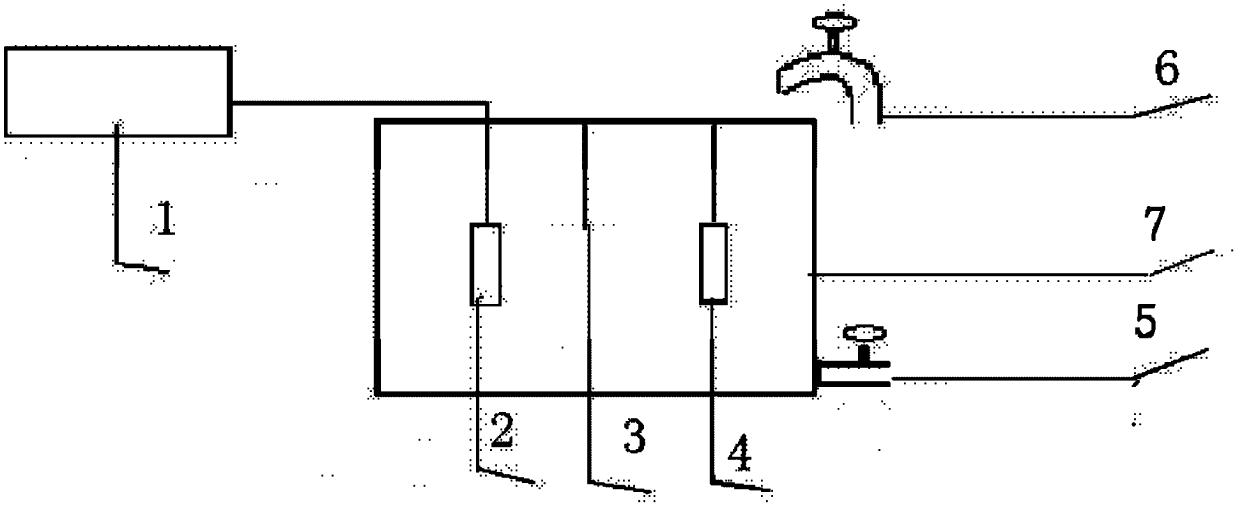

[0045] Step 1. Build 110m 3 FRP treatment tank 7 (including water inlet and outlet valve facilities), a three-electrode system is placed in the treatment tank—conductive carbon black paste electrode 2 with an area of 1m 2 , Columnar glassy carbon counter electrode 4 (model: AHDCL; diameter 2cm, working length 0.8m; Tianjin Aida Hengsheng Technology Development Co., Ltd.) and 217-type saturated calomel reference electrode 3 (Shanghai Yueci). The placement state of the working electrode is easy to take out and update, and the distance between the working electrode and the counter electrode is preferably more than 1m. There is no special requirement for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com