Fixture used for band saw machine tool

A technology of machine tools and band saws, which is applied in the field of fixing devices, can solve problems such as the inability to fix thinner workpieces to be sawed, and achieve the effects of easy adjustment, simple structure, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

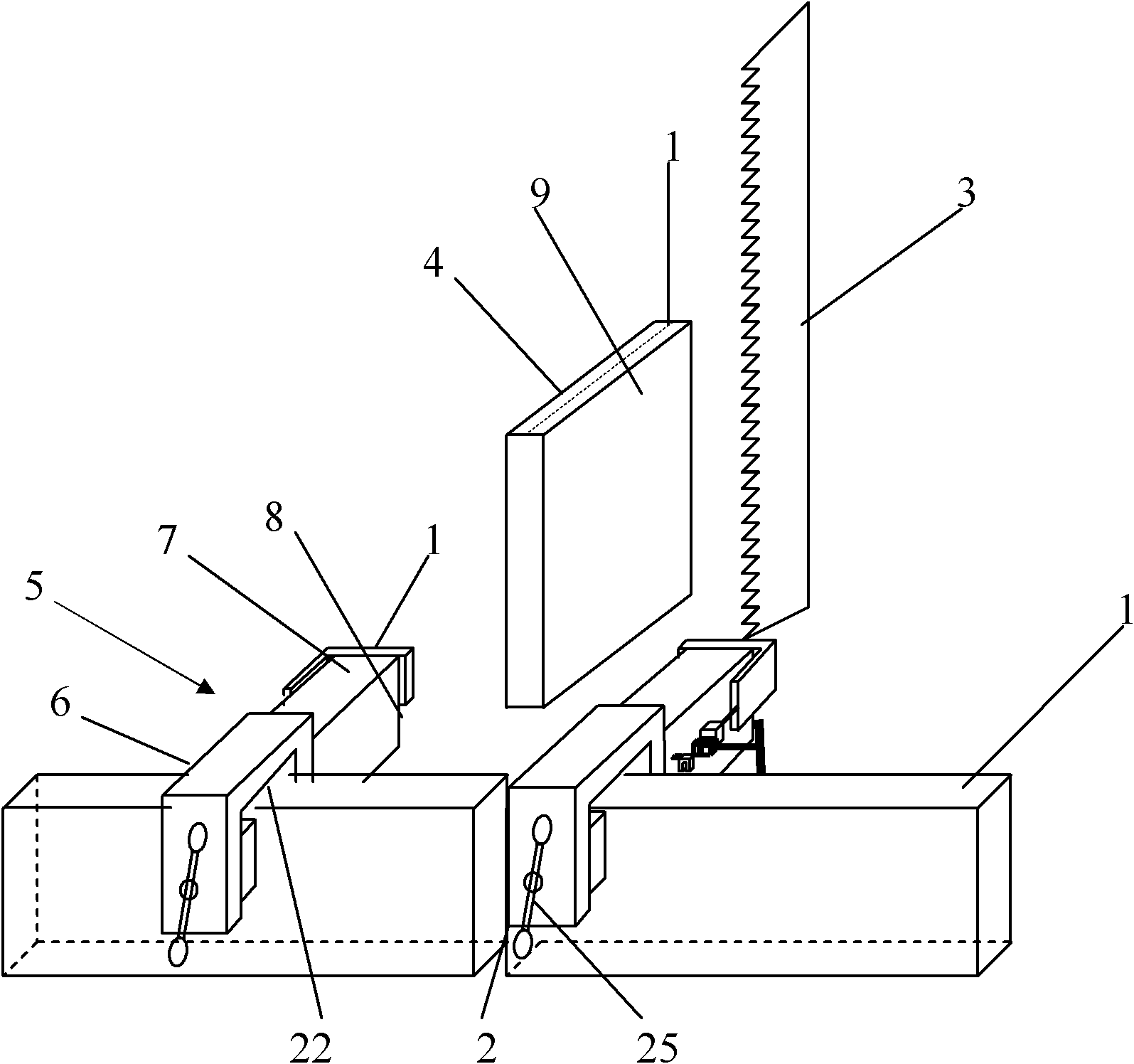

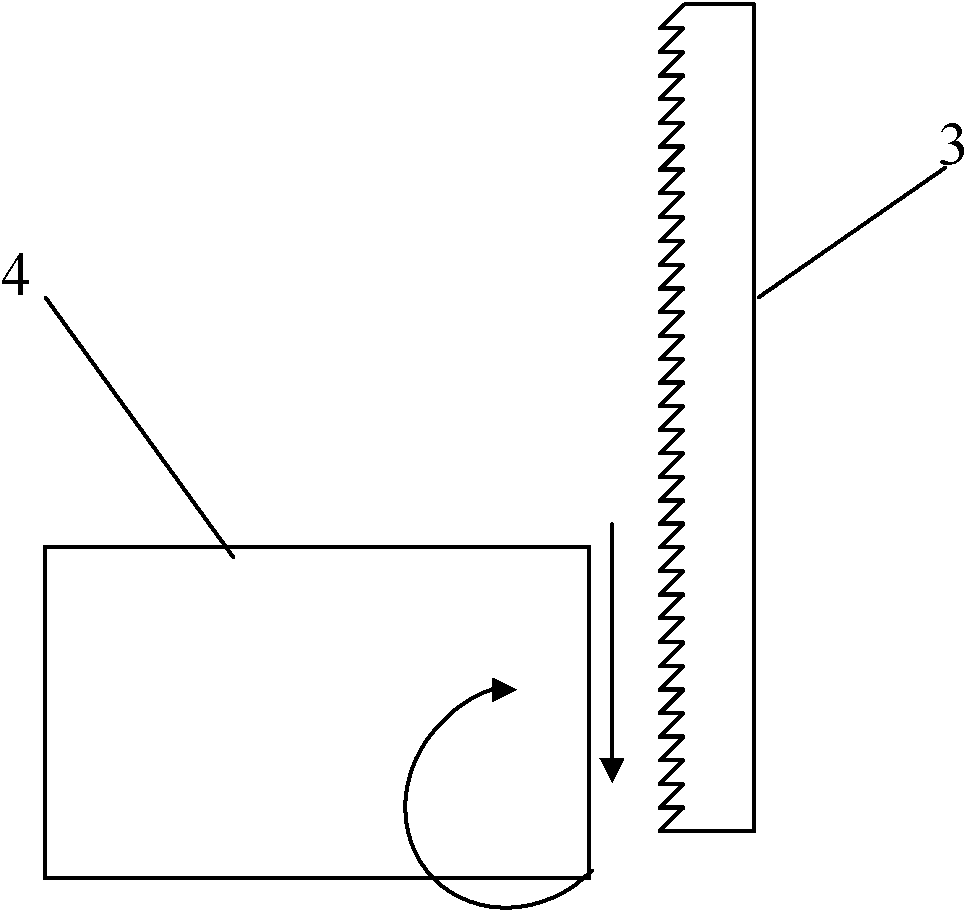

[0030] figure 1 It is a structural schematic diagram of an embodiment of the clamp for band saw machine tool of the present invention, as figure 1 As shown, the fixture of the band saw machine tool of the present invention, the band saw machine tool has a horizontal workbench for placing workpieces to be sawed, one side of the horizontal workbench is vertically provided with a clamping table 1, and the horizontal workbench And the clamping platform 1 is provided with a saw blade passing slot 2 perpendicular to the clamping platform 1 . In the working state, the saw blade 3 moves vertically, and as the horizontal workbench is fed horizontally, the workpiece 4 to be sawed is cut into two parts by the saw blade 3 . The clamp includes two clamping parts 5 arranged in parallel on the clamping table 1 , and the two clamping parts 5 are respectively fixed on the clamping table 1 on both sides of the saw blade passing slot 2 . In this embodiment, the structures of the two clamping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com