Method for increasing softening point of extract powder of traditional Chinese medicine extract

A softening point, traditional Chinese medicine technology, applied in pharmaceutical formulas, plant raw materials, medical preparations with inactive ingredients, etc., can solve the problems of increasing production costs, reducing economic benefits, reducing patient compliance, etc. Production time, effect of increasing softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of Cornus officinalis Extract Powder

[0030] Get 250 ml of the water extract of Cornus officinalis (ρ=1.035, solid content 0.35%), and spray dry it to obtain Cornus officinalis extract powder I.

[0031] Get Cornus officinalis water extract (ρ=1.035, solid content 10%) 250ml, add 10% plasdone S-630, 15% light magnesia and 1% maltodextrin according to the percentage that accounts for the solid content of extraction concentrated solution and dissolve and mix with Cornus officinalis The extract was mixed evenly, and after spray drying, the cornus officinalis extract powder II was obtained.

[0032] Determination of softening point

[0033] Utilize the Vicat softening point tester to measure the softening point of Cornus officinalis extract powder, and the experimental results are shown in the following table:

[0034] Table 1 Determination results of softening point of Cornus officinalis extract powder

[0035]

[0036] The experimental results showed th...

Embodiment 2

[0044] Preparation of Eucommia Extract Powder

[0045] Take 250 ml of eucommia water extract (ρ=0.994, solid content 0.35%) and spray dry to obtain eucommia extract powder I.

[0046] Take 250ml of eucommia water extract (ρ=0.994, solid content 0.35%), add 7% plasdone S-630, 7% light magnesium oxide and 3% maltodextrin to dissolve, mix with eucommia extract and spray dry to obtain Eucommia Extract Powder II.

[0047] Determination of softening point

[0048] Utilize the melting point apparatus to measure the softening point of Eucommia traditional Chinese medicine extract powder, the experimental results are shown in the following table:

[0049] Table 2 Determination results of softening point of eucommia extract powder

[0050]

[0051] The experimental results show that after adding auxiliary materials, the softening point of Eucommia extract powder II is significantly improved.

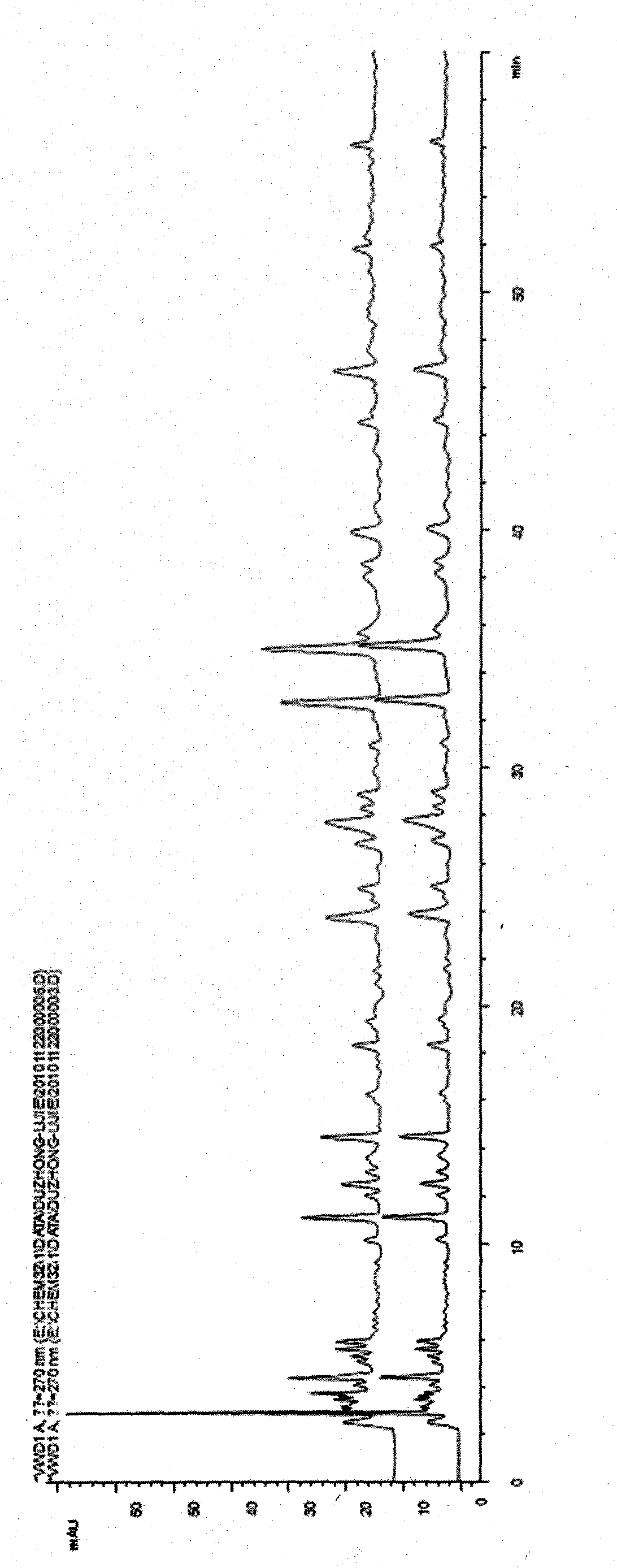

[0052] Investigation on the Interference of Compound Excipients on Effective Components...

Embodiment 3

[0059] Preparation of Hawthorn Extract Powder

[0060] Get 250ml of hawthorn water extract (ρ=1.01, solid content 6.8%), carry out spray drying, obtain hawthorn extract powder I.

[0061] Take 250ml of hawthorn water extract (ρ=1.01, solid content 6.8%), add 3% plasdone S-630, 8% light magnesium oxide and 5% maltodextrin to dissolve, mix with hawthorn extract and spray dry to obtain Hawthorn Extract Powder II.

[0062] Determination of softening point

[0063] The softening point of hawthorn traditional Chinese medicine extract powder was determined by melting point apparatus, and the experimental results are shown in the following table:

[0064] Table 3 Determination results of softening point of eucommia extract powder

[0065]

[0066] The experimental results showed that the softening point of hawthorn extract powder II was significantly improved after adding auxiliary materials.

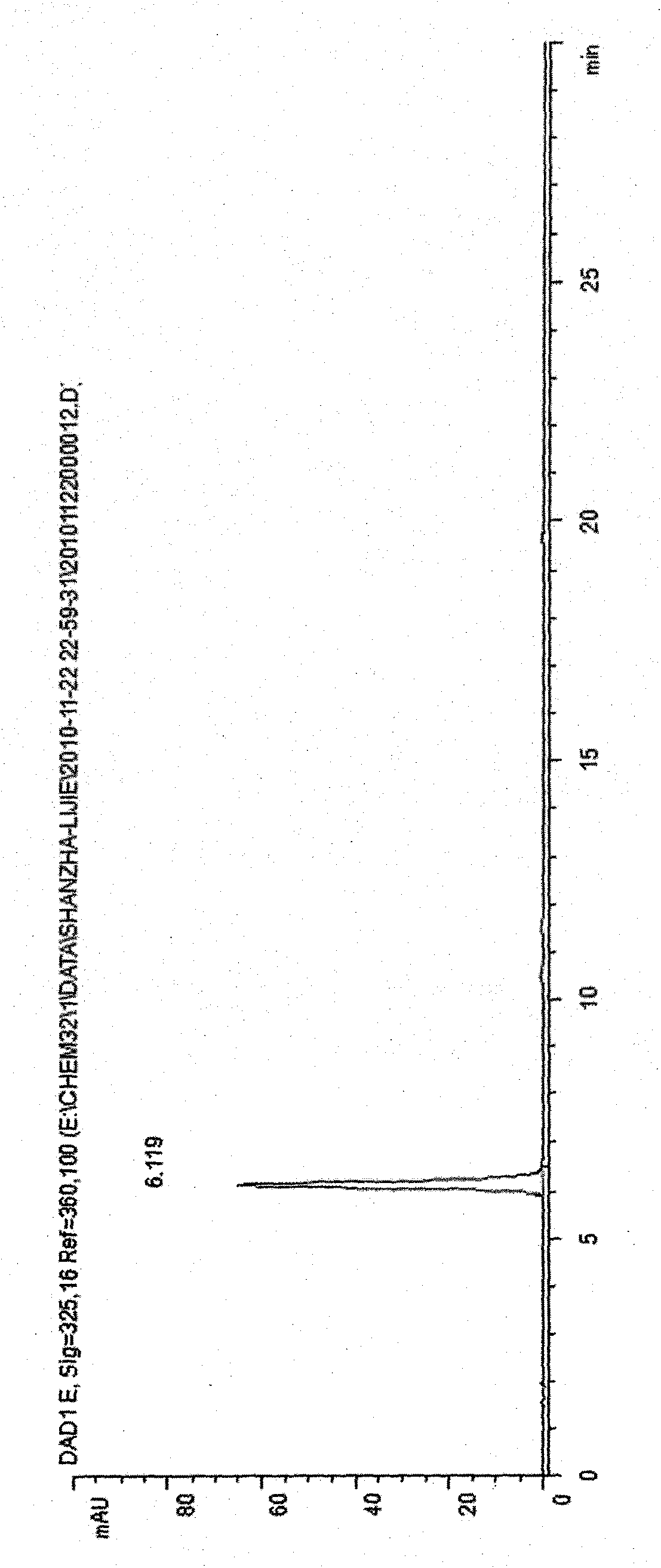

[0067] Investigation on the Interference of Compound Excipients on Active Components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com